April 14, 2014

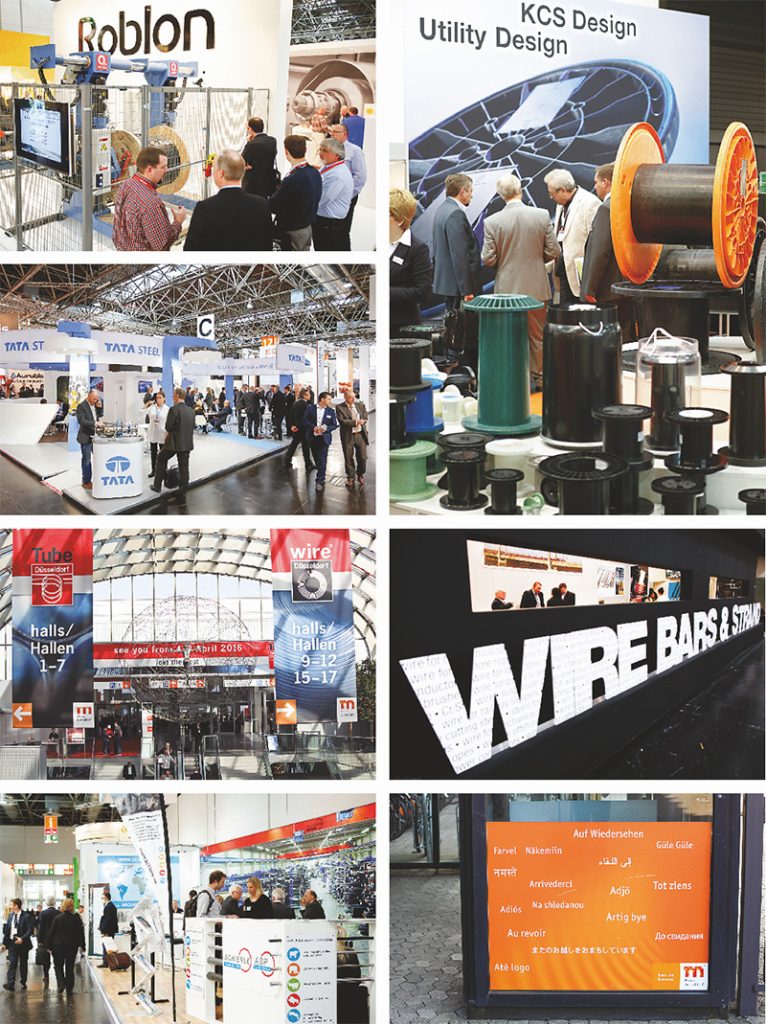

The upward trend continues: The more than 2,500 international exhibitors from the wire, cable and tube industries can look back on five successful trade fair days. Inspired by the upswing of the steel market, the exhibiting companies presented their product innovations at the Düsseldorf Exhibition Centre during the two leading trade fairs, wire 2014 and Tube 2014.

“The trade fairs took place at exactly the right time. Now several companies are planning on investing in order to position themselves for continued competition,” explained Joachim Schäfer, Managing Director accountable for the fairs at Messe Düsseldorf. “Once again, wire and Tube recorded exhibitor growth as well as a significant increase in booked exhibition space,” he continued with satisfaction.

Networked worldwide and globally active, the exhibitors presented themselves to the 72,000 trade visitors that travelled to the exhibition halls on the Rhine from 104 different countries. They came to learn about the latest machines, equipment and products for the wire, cable and tube processing industries at the no. 1 international trade fairs, wire – International Wire and Cable Trade Fair and Tube – International Tube Trade Fair.

International contacts, lots of conversations, healthy buying interest and actual closes, as well as the anticipation of interesting post-event business, characterised the mood at wire and Tube.

The steel and NE metal industry has long been considered to be a reliable early indicator for all other industries. The entire economy benefits when this market is strong.

In total, about 98% of the exhibitors gave top scores for the way the two trade fairs went. The companies exhibiting at both fairs occupied a total of more than 108,000 square metres of net exhibition space.

wire 2014

More than 1,300 companies from 54 countries journeyed to Düsseldorf for wire 2014. They occupied approximately 58,500 square metres of space – a 2% increase compared with the square metre figures from 2012.

The offerings in exhibition halls 9 to 12 and 15 to 17 ranged from machines and equipment for wire production and processing to tools and auxiliary materials for process engineering to materials and specialty wires.

Innovations from the areas of cable, measurement and control technology, as well as test engineering, were presented. Special fields such as logistics, conveying systems and packaging rounded off the offerings. The mesh welding machinery domain was presented combined under one roof for the first time – roughly 20 companies showed their products in hall 16. The range of products was very well received by the visitors.

Current forming technologies were presented in hall 15, while the latest spring-making methods were featured in parts of hall 16.

All applications involving wire, cable and fibreglass machines, wire and cable production, as well as trade, were located in halls 9 to 12, 16 and 17.

Manufacturers of tools for process engineering and companies that manufacture machines for wire production and processing were also extremely pleased with the course of wire. Material producers and companies that supply specialty wire and cable also consider wire to have been a success. The exhibitors particularly appreciated the professional competence of the visitors and the high level of conversations at the stands. Almost all of the companies surveyed expect good post-event business.

Visitors @ wire 2014

Overall, the trade fair visitors gave top scores for the quality of the exhibiting companies’ offerings, and considered their trade fair visit to be completely successful.

The percentage of international trade fair guests is traditionally high: 66% of the wire visitors travelled to Düsseldorf from abroad, representing a total of 70 countries.

The majority of all wire visitors came to Düsseldorf from classic visiting nations like India, the USA, France, Italy, Great Britain, Switzerland, Belgium, Spain, Sweden, Turkey, the Netherlands and Japan. The visitors came primarily from industry (75%), trade (11%) and craft (4%). Of primary interest to the visitors were machines for the processing of wire, steel bars and steel band (35%), machines for the fabrication of wire, steel bars and steel band (32%), end products (22%), assistive equipment (machines, devices, tools, consumables; 21%), forming technology (15%) and spring-making technology (11%).

Forecast: wire 2016 and Tube 2016

wire and Tube once again take place simultaneously from 4 to 8 April 2016 in Düsseldorf.

Successful WIRE 2014 Show for Enkotec

WIRE show in Düsseldorf was indeed a positive experience for ENKOTEC. Talking about the show Bent Just Petersen, Managing Director, Enkotec A/S sai, “Our many pieces of news were well received by the record-high number of visits to our booth and generated many specific requests. We had visitors from all around the world, proving that nail production is an international business and that Enkotec is a worldwide brand.”

At the Enkotec booth we displayed the following equipment:

1) ENKOnail+ NP02 nail machine running in-line with ENKOroll thread roller TA01 and wire coil collator CWC01 with fully auto-matic packing system PCC01, engineered and manufactured by BAUSSMANN. This line is capable of producing up to 2500 nails per minute.

2) ENKOnail MM01 nail machine running in-line with ENKOpack NCP02 packing system and featuring our nail head-marking system. The PD01 payoff was running with ENKOTEC’s wire coil fixation unit.

3) Our brand-new ENKOllator paper-tape stick collator, type CTS01, running as a standalone machine. The CTS01 is prepared for in-line set-up with our ENKOnail+ nail machines. This line was running at a speed of 1600 nails per minute during the show, and it was equipped with our new ENKOfeed feeder bowl.

Both the ENKOllator paper collator and the ENKOfeed bowl are in a test stage and therefore have not yet been released for sale. Both systems will go into field-test after the Wire 2014 show with expected release later this year. Enkotec test procedures call for 500 – 1000 hours’ production run before new equipment can be released for sale.

.

PolyOne Showcases Solutions for Efficient Manufacturing at WIRE 2014

PolyOne Corporation, a premierglobal provider of specialized polymer materials, services and solutions,featured solutions that help wire and cable manufacturers to boost efficiency and reach their sustainability goals at the WIRE 2014 trade show.

Holger Kronimus, PolyOne vice president Europe and general manager, Specialty Engineered Materials Europe, commented, “We’ve recently developed several technologies in close collaboration with customers that help toimprove manufacturing efficiency while also addressing the need for sustainable operations and products.”

PolyOne solutions help wire and cable manufacturers meet many of the challenges facing the industry. Recently introduced offerings include:

• ECCOH XLS, a moisture-cured technology that helps manufacturers reduce production and operating costs

• Next-generation FireCon™ CPE (chlorinated polyethylene) RoHS-compliant material for wire and cable jacketing that processes 30% to 70% faster and reduces scrap for improved profitability without compromising performance

• ECCOH LSFOH formulations for elevated temperature wire and cable help to meet UL requirements, maintain equipment flexibility, streamline secondary processing, and reduce scrap.

.

Rosendahl and Nextrom had an intense & successful show

Wire 2014 was an intense and successful show for Rosendahl and Nextrom! They say the atmosphere and the spirit at the exhibition and their booth was enthusiastic. Partnerships and business relations have been intensified and they celebrated their closed deals, birthdays of colleagues and customers and their new developments which they had on display in Düsseldorf. Rosendahl’s RX180 crosshead for example. It is the largest of Rosendahl’s crosshead series which is used for single layer applications with up to 2 stripes for a max of 180 mm outer diameter products. Not only the exhibit was an eye catcher for itself. Rosendahl and Nextrom always manage add-ons to their products. This time it were two beer taps in the crosshead that have been well adopted. Nextrom’s highlight was its new high speed DFT 2500 dual fiber take-up. The automatic change over at full line speed allows a continuous drawing process and minimizes the scrap with long fiber lengths. The audience’s attention was great for the daily live-stream to Nextrom’s factory with the running loose tube line OFC 40. This line is running at speeds of 600 m/min which is a new break through in loose tube production.

.

Huntsman launches new products completing comprehensive Wire & cable portfolio

Huntsman, a global leader in the development and manufacture of polyurethane, announced the launch of a number of new thermoplastic polyurethanes (TPU) for the wire and cable industry. The products were unveiled on the first day of Wire – the international trade fair taking place in Dusseldorf, Germany.

The new products, all available under the IROGRAN® TPU brand, complement Huntsman’s existing wire and cable portfolio, and enhance the company’s offering in three fields: standard ether solutions; UV stabilized TPUs for offshore applications; and high flame retardant grades aligned to clear market demand for higher safety solutions.

Each new TPU grade was developed following careful market evaluation and extensive discussions with Huntsman’s customers, and each offers outstanding performance and processing properties for the application it was designed for.

Two new high performance ether grades – IROGRAN® A 80 P 5039 and IROGRAN® A 95 P 5044 – have been created. IROGRAN® A 80 P 5039 gives customers a solution for applications where softer grades are needed for high flexibility cables. IROGRAN® A 95 P 5044 is a harder solution that gives wire and cable manufacturers the chance to reduce wall thickness and achieve cost efficiencies, without losing any of the benefits typically associated with TPUs. Both materials are particularly well suited for cable jacketing for sensor cables across the wire & cable market.

In offshore applications, cable solutions need to offer high UV stability; a requirement Huntsman has responded to by producing IROGRAN® A 85 P 4394UV and IROGRAN® A 92 P 4637UV. These new UV-stabilized developments offer outstanding performance and physical properties in this growing market segment and give operators the safety they need from materials employed in extreme environmental conditions.

The third group of new products has been developed in reaction to the trend for harder, higher flame retardant solutions for industrial applications where safety is a priority.

The products, IROGRAN® A 89 P 5028DP and IROGRAN® A 89 P 5012DP, offer excellent hydrolysis and microbial resistance, and close the gap between the existing Shore A 85 and Shore A 95 products available in the Huntsman IROGRAN® portfolio. The new materials offer high flame retardancy without compromising physical or functional properties. Ideal for technical extrusion and injection molding applications, IROGRAN® A 89 P 5028DP is a harder version of IROGRAN® A 85 P 4380 – a well-established brand in the cable industry. The new grade offers outstanding extrusion and dimension stability. Additionally it meets UL 94 V0 standards.

.

PWM celebrates 30 years of service at wire 2014

British company PWM (Pressure Welding Machines) Ltd celebrated 30th years of service to the wire and cable industry at wire 2014.

PWM, based in Kent, England, designs, manufactures and supplies high-performance cold welding machines and dies to wire and cable manufacturers worldwide.

PWM’s first machines were small, manually operated cold welders for joining fine wire and strip. The M10, M25, and M30 models for wire sizes 0.10mm to 1.80mm, are all still produced today.

Over the years, PWM gradually expanded its range and introduced larger, powered cold welders, including the P1500 rod welder for joining large rod sections up to 30mm diameter. Recent innovations include the portable air/hydraulic powered HP100 and HP200 machines, which provide effortless welds on wire and strip 1mm to 5mm and 2mm to 6.50mm. All PWM machines and dies are precision engineered in-house to stringent quality standards by PWM’s own team of skilled engineers and technicians.

PWM has a worldwide network of experienced agents who, together with its UK team, provide fast and effcient on-site support with full back-up and after-sales service.

PWM’s on-going research and development programme ensures that it continues to offer wire and cable manufacturers the most advanced and comprehensive range of cold welders in the world. To explain the cold weld process, the company recently developed a series of videos demonstrating the technique, which can be viewed at its website.