Viraj Profiles has the history of doing things differently, capturing the first mover advantage and setting its own niche. With this vision they have once again embarked on the expansion regime with the commissioning of new section rolling mill spanning in 10 hectare of land and equipped with most recent technology available globally. And this is the good time to go into their strategic mode and explore more about what they are upto!!!

Below are the edited excerpts of the interaction Team Wire and Cable India (WCI) had with Mrs. Renu Kochhar, Managing Director, Viraj Profiles Ltd

WCI: First of all a look back on 2013, how it has been for Viraj Profiles along with the current status of the business?

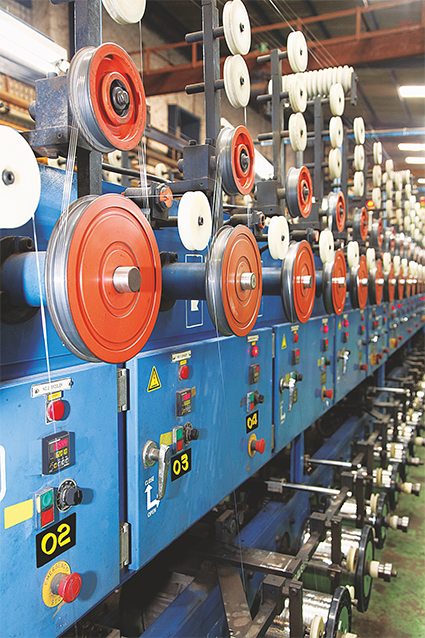

Renu Kochhar (RK): The past year can be summarized in a few words: In the face of significant challenges, we made significant progress. Amidst the challenging business environment, we delivered another year of strong performance and solidified our leadership in the industry by turning risks and challenges into opportunities and continuously enhancing competitiveness and innovation. While there is much work to do and there may be further challenges ahead, we step into the year 2014 with a vision to expand ourselves in all aspects and be able to serve our customers and clients in better and more efficient manner. The year gone by witnessed one major milestone in our journey–commissioning of new Section Rolling Mill. Equipped with completely automated process, the plant is first of its kind in the country on an industrial scale.

The use of fully automated process will not only help us in increasing our production capacity rather it will also give us more flexibility in plant operations. We aim for continuous development and growth of the business in manufacturing stainless steel engineering products. The new facility will allow us to strengthen our business both locally as well as globally. Currently we are catering to the huge global demands of our products from customers base spread across 6 continents, more than 90 countries and to around more than 1300 customers and with the new plant we are hoping to serve our customers better and better and spread further our footprints globally.

WCI: What strategies do Viraj has made to combat the current situation of economic slowdown, stagnant demand and oversupply situation?

RK: Though, it is a fact that the global economy has witnessed a slowdown last year but with two decades of marketing and business experience, Viraj enjoys a strong reputation in the overseas market. Our preparedness to take decisive action has established our reputation as the undisputed leader in stainless steel long product manufacturing. With a rich history of constant progress, Viraj has become today one of the largest producers of stainless steel engineering products in the world. We have been exporting stainless steel flanges, bars, fasteners and many other products to several countries in Europe, USA, Australia, Middle East and other Asian countries. Our long list of satisfied customers have always looked upon us for delivering quality products at assured delivery time and we are happy to share with you that we did not let them down in any ways. As a matter of fact we added lot many new customers for our existing product lines in the last year and all this has been possible because of our strong commitment to continual growth through excellent customer service, innovation, quality standards, up-gradation and adaptation of latest technologies etc. Our production planning wing works in sync with the customer demand while utilizing the production facilities at optimum value. We offer real time based CRM services to all our customers wherein the customers can log into our system and see the actual status of their order at any given point of time. This service has proved to be a boon for our customers as well as for us since it helps us in planning our production schedule more efficiently and thus avoids the situation of over production or under production.

WCI: Share the new developments at Viraj?

RK: Viraj Profiles Ltd, one of the largest producers of stainless steel engineering products globally recently started its new state-of-the-art section rolling mill (SRM) plant in Tarapur, Maharashtra, India. Equipped with completely automated process, the plant is first of its kind in the country on an industrial scale. The plant is quite unique in terms of online pickling facilities, automatic labeling inter-alia packaging line. This new facility would be able to manufacture more than 700 different shapes and designs of angle, flats and other profiles. With the new plant in place, the company which has created a niche for its products globally; hopes to deliver world class quality products at assured delivery time and thus, increasing its efficiencies in catering to the significant global as well as local requirements. Commissioning of this new plant is a bright example of group’s commitment to its strategy of modernization of the facilities and increasing the production volumes. The annual capacity of this plant will be up to 180,000 MT per annum. The plant, which is spread across around 10 hectares of land, boasts of some of the best machineries in the world in stainless steel industry. The new project has been implemented within the scope of Viraj’s strategic investment program targeted at production facilities modernization; improved products quality, rise in production volumes and increased output of high added value products. The plant complies with the high environmental standards of modern stainless steel manufacturing and has level – 2 automation processes.

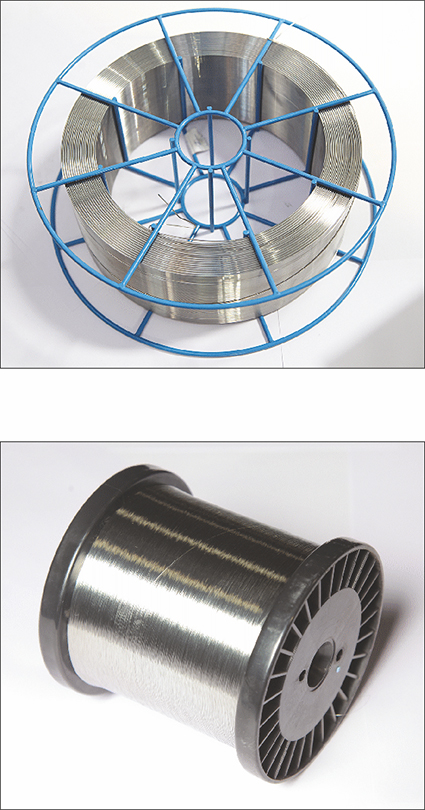

WCI: Your views on the challenges and opportunities for the wire industry in the next 2-3 years and what steps should be taken to overcome them?

RK: With the signs of recovery in the global economy overall, stainless steel wires in recent years has been extended to the application range of the, chemical fibre industry, covering oil pipeline, boiler heat preservation, antifreeze, civil engineering and construction, supplies and other fields, and the demand of market is set to get bigger and bigger. Today stainless steel wires and wire rods are used across various industries like ship building, medical, agriculture, springs, vineyard, petroleum, automobile, weaving braiding, fastener, food processing, paper mills etc. Growth of stainless steel wire industry, a part of stainless steel industry is dependent on a number of factors such as level of economic activity, and state of the end use industries such as construction and automotive industry, which are some of the major consumers of SS wires. Growing investments in infrastructure and higher disposable incomes in several developing economies are key factors driving growth in stainless steel and its derivative products. In light of this, several new technologies were developed to meet demand for high-quality SS wire rod products from construction and automotive industries. These technological innovations in the field of dimension, measurement, improved finishing operations and rolling with precision tolerances; ensured consistency in dimensions, finish, and mechanical properties. Going forward, the economic conditions globally have started showing good signs and rapid expansion and industrialization in developing countries are indicating that the future of SS wires as a product will also be bright. However, this product alone might not see a major shift in its demand pattern but combined with other products, it is surely set to see a new height in its demand.

In order to keep up with the changing trend in the market and the changing global scenario, customer’s specification about quality standards, being competitive the manufacturers will have to focus on newer and better technologies which can enable them to produce better quality of products. Investments in new technologies will surely reap you benefits in the time to come. This new facility has several locational advantages as well. The nearest railway track is merely 8 kms from the production site and the nearest port is around 170 kms only. Inland container depot (ICD), started by Viraj Profiles at Tarapur will ensure smooth logistical support to its clients. The combination of the specific design and fully automated process coupled with smooth logistics arrangement allows for a reliable and consistent production and supply of high quality products at optimum operational economy. The new facility will help Viraj to serve current and future markets in a more efficient manner.

WCI: What do you think about the role of different countries as part of your global footprint?

RK: Globally stainless steel is set to witness a surge in its consumption. Today, stainless steel has become one of the most important and reliable materials in various industries globally. Therefore, stainless steel consumption has been rising continuously across the globe. Stainless steel products are used in a wide variety of applications including consumer goods, architecture, building and construction, food and beverage industry, transportation, chemical, petrochemical, oil and gas, pulp and paper industries, and power generation. Moreover, it is expected that stainless steel consumption will increase further in future with rising demand in various sectors. Viraj will be the first to reap benefits of rising demand within India.

The Middle East market holds much potential for us, due to the inherent applications for our products in the oil and gas industry. Similarly, the construction industry is extremely active in that region. Dubai and Abu Dhabi are highly promising considering the fast rate of architectural and construction activities happening in that region. Even countries like Iran and Iraq are recovering from recent socio-political developments. Together with tremendously large-scale oil and gas projects that are being realised in the area, we feel confident that we are fully equipped for offering a product portfolio as per the requirements of Middle Eastern customers.

On a larger scale, as the stress on maintaining environment is growing day by day and companies are becoming more aware about their responsibilities towards creating a greener earth, what better option do we have than stainless steel which is 100 percent recyclable material and long lasting and turns out to be very cost effective considering its low maintenance and longevity. Even developing countries are becoming aware of this fact and have started adopting this wonder material called stainless steel in big way.

WCI: What are your expectations from wire and Tube 2014, Dusseldorf and what new products will be showcased by Viraj Profiles?

RK: Wire and Tube Expo being held in Dusseldorf is one of the biggest fairs in this industry and Viraj has been participating in this expo from past couple of years and the response has been quite encouraging. It gives us a great opportunity to meet up with so many customers, suppliers, partner’s etc all under one roof. The exhibition works as a wonderful platform not only to strengthen the relationship with existing partners but also in nurturing relationship with new partners. Rounds of meetings and discussions held with such a large number of people from the industry actually gives you a clear insight about the market trend, where the market is going, what are the changes in the global demand and supply pattern, where is the gap between the need and supply, the level of competition, new technologies which can further help the company in improvising its manufacturing etc. and paying heed to these feedback, you can always prepare a roadmap for your company to see how you adapt yourself in line with these changes.

As far as product launches are concerned, we have decided not to launch any new product this year. Our focus is on consolidating our business and strengthening our existing product lines with technological advancements and by investing in procuring new technologies and machineries, which shall increase our efficiency and help us in bringing out better quality products. Viraj has commissioned a fully automatic section rolling mill in Tarapur, Maharashtra and that will be one of the major highlights for us there in the expo. The plant is likely to be fully operational by the month of April 2014.