As a 115-Year-old global lubricant supplier, RichardsApex manufactures world class lubricants for both wire drawing and hot rolling applications. Its products include – semi-synthetic and synthetic lubrication compounds for wet drawing of non-ferrous (copper, aluminum, brass etc.) and ferrous wire. In addition, the protective coatings, cleaners, corrosion inhibitors, and oil form lubricants for all non-ferrous and ferrous alloys are also available in both wire and rod rolling applications.

RichardsApex currently supplies over 95% of the lubricants and protective coatings for the manufacture of copper wire rod within the Indian market (SK series, HRAL & CC40); thus, our understanding and technical expertise of rod and wire is our core competitive advantage. The company is one of the few lubricants suppliers globally, that can provide the lubrication products and technical expertise, from the copper rod manufacture, right through the process to the final drawn wire.

With today’s machines performing at peak efficiencies, customers are demanding more from their lubricant suppliers. Our teams of scientists are constantly looking for new technologies to bring to the market that will exceed our customer’s expectations.

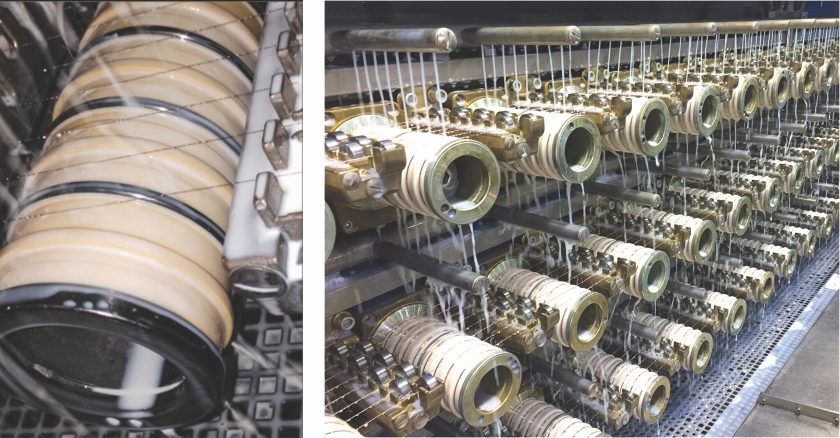

In recent years, RichardsApex responded to the market request to develop a modern, water-soluble copper wire drawing lubricant. Over several years and demanding on-site testing, RA400 was developed and designed to meet the rigorous demands of our global wire drawing customer base. It incorporates specific friction modifiers for today’s advanced machinery; die’s and speeds, combined with a lower lubricant consumption, compared to competitive products.

RichardsApex’s RA400 produces a stable, low foaming exceptionally clean running emulsion that will not generate excessive copper soap formations. The RA400 technology also supports improved tank life and wire drawing performance, through fewer wire breaks per tonne of wire produced.

Suitable for copper, copper plated alloys and EC aluminum, RA400 can be used for rod breakdown, single and multi-wire machines as well as inline annealing. With a proven track record of success in a wide variety of operations, RA400 stands alone as an ultra-modern, universal wire drawing product. RA400 has quickly become the company’s fastest growing wire drawing lubricant based on its global success and market exposure.

With over 115 years of history, the company has an established global sales network to service customers throughout the world. This network provides on-site support and technical sales assistance, to help you improve productivity, enhance quality, and reduce your manufacturing costs.

RichardsApex has been a proud supplier of lubrication products to India, for well over 60 years and currently have both employees and product representatives within the key Indian market. The company’s service philosophy remains integral to their decades of success globally in wire drawing, copper tube production and rod rolling markets. It remains committed to providing a product and service that adds value to the long-term relationship with our Indian and global customer base.

RichardsApex maintains a network of global subsidiaries based in AustralAsia and Europe. The company also has representatives in India, China, Japan, Korea, Malaysia, Vietnam, Taiwan, Thailand, UAE, South Africa, Canada, Venezuela, Mexico, Brazil, Peru, Russia, Italy, Romania, Poland, Greece, Turkey, Ukraine, Belarus and Kazakhstan.