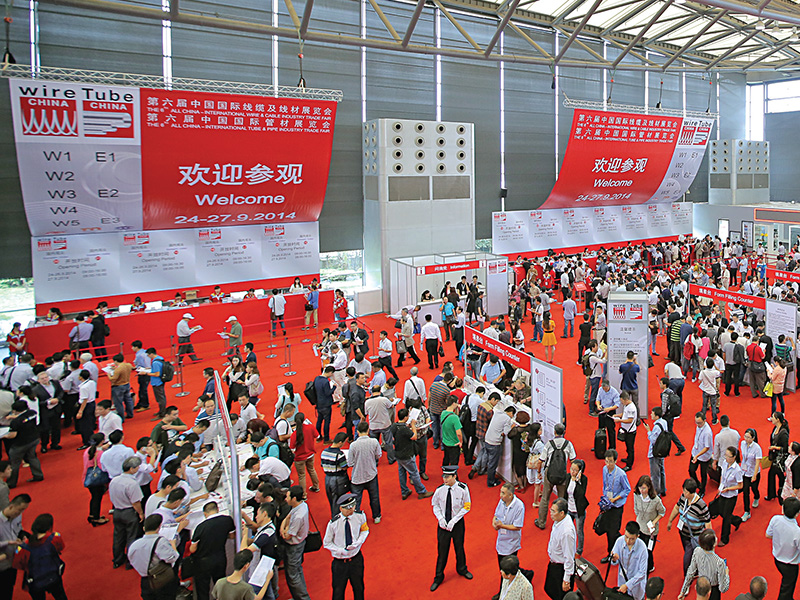

From 24 to 27 September, 2014, Asia’s No.1 and world’s No.2 wire & cable, tube & pipe industry exhibitions, the 6th All China – International Wire & Cable Industry Trade Fair (wire China 2014) and the 6th All China – International Tube & Pipe Industry Trade Fair (Tube China 2014) was held concurrently again in Shanghai New International Expo Centre. Renowned companies and leading brands in the world presented their advanced technologies and innovative products here after two years. Industry experts from all over the world met at this business and sourcing platform. On the first day of the exhibition, 13,475 visitors were attracted to these two grand shows.

Booming Opportunities with 10-year Accumulation

Thanks to a decade of effort, the quality, services, scale or level of wire & Tube China have been recognized by the entire industry. The continual economic growth of China with immense infrastructure and energy projects has lead to a boost in the already huge market demand for all kinds of wires, cable and pipes. In only 10 years, wire China and Tube China have become Asia’s No. 1 meeting point for industry and buyers.

No matter the exhibition area, or the exhibitors, or the visitor delegations, the fairs have broken the records with the total exhibition area of 90,000 sqm, attracting more than 1,400 exhibitors. Besides the numerous domestic renowned exhibitors, countries and regions pavilion from Germany, Italy, Austria, France, North America, Spain, South Korea, Japan and Taiwan Region will display advanced production technology, skills and products. The total exhibition area of wire China 2014 reaches 57,500 sqm; and Tube China 2014 occupies an area of 32,500 sqm in total. Both fairs continues to lead the industry and serve as a perfect platform of establishing new business contacts and maintaining existed customer relations.

Good Visitor Organizaiton to Ensure well-covered Visitor Profile

Professional visitor organization is always a highlight of wire & Tube China. In order to enhance the organization of domestic professional visitors and effective information delivery, the organizers adopted various campaign channels including WeChat, weibo, call center, text message, mail, fax, media cooperation, and on-site campaign, etc., posting the information of fairs and exhibitors to targeted wire enterprises and industry clusters home and abroad. Efforts for inviting and organizing visitors abroad has revved up compared with those in the predecessors. Owning to the reputation of the fairs around the world and powerful campaign networks of organisers, as well as substantial support from industrial associations and media, organisers have tapped deeply into the professional buyer resources locally and in Asian countries coupled with one-on-one invitations. In additional, large international visitor delegations from countries and regions including Argentina, Thailand, Vietnam, India, Japan, South Korea, Kong Hong, Macao, Taiwan Region and so on will visit the shows.

High-end Industry Forums to Share Expertise Insights

wire & Tube China 2014 is an excellent platform not only for business and trade communication, but also for the exchanges and business development among professionals. During the fairs, various events were organized including industrial conferences and technology workshops, etc., where many established industry players had communication and discussions.

wire China 2014 is jointly organized by Shanghai Electric Cable Research Institute and Messe Düsseldorf (Shanghai) Co., Ltd., while Tube China 2014 is jointly organized by Metallurgical Council of the China Council for the Promotion of International Trade (MC-CCPIT) Metallurgical Center for International Exchange and Cooperation and Messe Düsseldorf (Shanghai) Co., Ltd. After a decade of devoted efforts, wire & Tube China now serves as a well-recognized scientific and technological platform for business and trade of wire and tube industries and an indicator of industrial development.

New Borlink™ grade enables DC transmission in extruded cables at extra high voltage levels

Borouge and Borealis, leading providers of innovative, value creating plastics solutions for the wire and cable industry, showcased their recently launched Borlink™ LS4258DCE, a step-change innovative grade for high voltage direct current (HVDC) cables, at the Wire China 2014 in Shanghai, China.

The power transmission and distribution industry is continuously looking for cables with higher power transmission capacity at high voltage levels. The next generation HVDC insulation compound, Borlink LS4258DCE, together with the HVDC semi-conductive, Borlink LE0550DC, addresses this trend by enabling the use of extruded cable technology at voltage and power transmission levels where traditionally only paper cables could be used. According to the Cigré recommendation 496, a successful type test qualification of an extruded cable system based on Borlink LS4258DCE and Borlink LE0550DC has been achieved at a voltage level of 525kV. This exceptional performance is made possible due to the unique production process of the compound, providing a high level of both chemical and physical cleanliness.

Borlink LS4258DCE is an unfilled cross-linked polyethylene (XLPE) compound based on the enhanced base resin technology Supercure. The technology allows higher cable production efficiencies by shortening the cable production cycle via significantly reduced degassing time and improved scorch performance.

This major HVDC innovation, supported by a unique 15-year track record of proven operational excellence and industry leadership in extruded HVDC materials, will support the further integration of various types of renewable energy into grids and the establishment of more interconnections among countries in major infrastructure projects around the world.

At this Wire China exhibition, Borouge and Borealis highlighted their innovative plastics solutions for the cable making industry, offering the best-value-for-money solutions of consistent high quality:

Borlink LE4212, Borouge and Borealis Water Tree Retardant (WTR) insulation solutions for medium voltage cables significantly improve the long term reliability of cables.

Visico™ LE4423 and Ambicat™ LE4476, Borouge and Borealis’ solutions for low voltage cables, significantly reduce cable production complexity via superior scorch performance and fast, ambient curing.

Borouge’s new 350,000 t/y low density polyethylene (LDPE) plant, which is an important part of the Borouge 3 expansion project in Abu Dhabi, will be an integral addition to the recently inaugurated Borealis’ high pressure LDPE plant, dedicated to the production of highly specialised and super clean products for the wire and cable industry. Borouge’s new LDPE production plant is tailored to manufacture unique Visico™ and Borlink™ XLPE solutions for the global wire and cable market, thereby applying the same technology and quality standards applied by Borealis.

“Borouge’s role as a leading, global innovator that is truly committed to the wire and cable industry will be further enhanced by this step-change capacity expansion, supporting the future growth of the industry,” said Roland Janssen, Borouge’s Vice President Marketing Centre Wire & Cable. “In line with our goal in Bringing energy all around, we will continue to cooperate with partners and customers across the value chain to deliver tangible benefits not only for the wire and cable industry, but for the society as a whole.”

Successful Show for Maillefer

Once more Shanghai hosted the Chinese cable industry as well as many other international players. The exhibition was more international than ever before. Many familiar faces visited from the neighboring countries, but also extensively from the South East Asia region in general. We received more than 300 visitors from about 120 different companies.

A successful seminar was also held during the exhibition. Maillefer participated with three different topics presented by Doctor Pekka Huotari, Product Manager Heikki Saastamoinen and Product Manager Ramiro Rodriguez. They addressed exciting new solutions in “Perfect Roundness of extra high voltage cables”, “High efficient building wire manufacturing” and “Zero default aviation wire manufacturing”. An audience of more than 150 from research institutes and cable manufacturers attended the seminar and posed some very good questions showing in-depth interest in the issues.

Based on the discussions it seems that many of the Asian cable companies look in the future positively. In addition to the investments for growth in traditional business sectors, companies are looking for new business possibilities.

State-of-the-art solutions in terms of manufacturing productivity and end product quality draw attention more than before. The total cost of ownership including labor costs, material savings etc. is ever more on the table when talking about solutions for building wire, low voltage and optical fiber cables. Generally speaking, today cable quality is a must, especially in high voltage cables where it is taken to its maximum. Not only the electrical properties, but also the perfect cable roundness is recognized to be vital, minimizing the waste of material and maximizing the reliability in high voltage power cable systems with better joints and terminations.

Wire China Draws METALUBE Distributors

Leading lubricants manufacturer METALUBE experienced an excellent Wire China show with record numbers to its stand.

To coincide with the show METALUBE hosted a SE Asia Distributor Conference at the Shanghai, Ramada Hotel. Included were METALUBE representatives from India, Malaysia and China.

Douglas Hunt, Commercial Director says: “When you are an international company such as METALUBE it is vital to bring teams together, giving them the opportunity to work collectively towards joint goals. Using Wire China as a platform for a conference worked fantastically well. The event provided briefings on the latest new product developments from the UK as well as training and sales tools.”

He adds: “Most importantly, it allowed colleagues from different markets to not only attend the Wire China show but to also get together and share experiences and ideas.”

An event with huge triumph for SAMP

he Wire China show has definitely confirmed its status as the most important international trade fair for the wire and cable industry in Asia.

“It was an even greater triumph than we expected”, said Dominique Perroud, Managing Director of SAMP Shanghai. “The 2014 edition of Wire China had an extraordinary number of visitors and a powerful media impact, and it also reaffirmed its international vocation. All this gave us an opportunity to show ground-breaking innovations from our comprehensive range of wire and cable manufacturing solutions for sustainable and efficient manufacturing. We were pleasantly surprised by the interest of customers and by the quantity of new sales contacts that were made throughout the exhibition. The Wire China show surely met and even exceeded all of our expectations.”

SAMP, the global provider of turnkey solutions for the wire and cable manufacturing, has presented many technological innovations at Wire China 2014, including hi-tech rod breakdown machines for non-ferrous wire, double-twist bunchers and innovative spoolers.

One of these breakthrough machines is the new Double-Twist Bunching Machine BM 630 E, a high-performance, enhanced version of our best-selling buncher, characterized by an innovative energy efficiency architecture for high Power Factor, the possibility of an infinite adjustment of the main production parameters at the control panel and the ability to run without human intervention thanks to the SAMP Automatic Traversing System. The key features and technical solutions adopted are the result of careful analyses of our customers’ requests.

SAMP looks back with fond memories to the event since Wire China 2014 coincided with a major milestone in the company’s history: the 10th Anniversary of SAMP Shanghai. Indeed, the SAMP Group has been active in China since 2004. In 2011 the decision was made to further strengthen its local presence, investing in a new state-of-the-art production unit to efficiently and safely produce high-quality machinery and equipment with minimal environmental impact. With its over 3,800 sqm (3,000 sqm workshop, 800 sqm offices), SAMP Shanghai has almost doubled its original size.

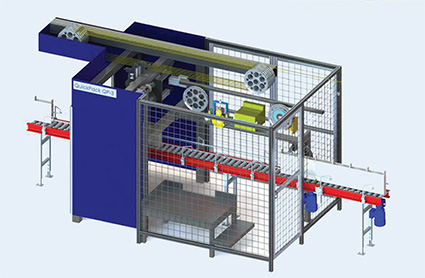

QuickPack: a show stopper for Windak at Wire China

Windak Group has been participating in Wire China since year 2008. Each visit to Wire China has been very productive for our company, not only do we get to meet new and existing customers but in addition we do get information of new trends and the general market situation. Wire China has grown to one of the major event for the cable industry, involving many visitors and suppliers.

Many organisations and companies have based cable production in China due to the large market and potential sales. The general labor cost is under increase and with the rising costs so increases the requirement in automatic equipment. Windak has a good solution for all customers who seeks to expand their business and to make it more efficient.

Windak stand has been very popular during trade show. Our visitors have been more than satisfied with our equipment and services. Our latest offers through our new line QuickPack QP3, a fully automatic cable coiling and packaging machine, has been extremely popular. Its concept is based on absolute simplicity and maximum out-put. The model has been designed in order to accommodate a range of product diameter up to 7mm with maximum speed up to 8 coils per minute. This new generation machine is faster, with more servo control and less settings, thereafter it gives our customers a quicker return.

Again Wire China showed us that trade shows are very important for business development, industry knowledge and co-operation.