“The new facility in Vapi, Gujarat will set new benchmarks in quality and great cost savings for our customers, making Systematic the lowest cost producer of cable armour wire.”

Systematic Group is one of the leading GI wire manufacturers in India and a reliable supplier for hot dipped galvanized wire, high carbon & low carbon steel wires, and ACSR wires. The company exports its products to many parts of the world including Asia, Africa, and Europe. In an interview with Wire & Cable India magazine, Mr. Sidharth Agrawal, Managing Director, Systematic Group talks about the accomplishments of the company, its new production facility, product portfolio, machinery installed, and emerging trends in the galvanized wire segment.

Wire & Cable India: Systematic Group has been serving the Indian wire industry with a range of wires and wire products for more than two decades, please shed light on some of the notable accomplishments of the company.

Sidharth Agrawal: Systematic Group has been in the wire industry since 2000. We have five manufacturing locations in and around Gujarat and Silvassa region. We were amongst the first EPA partners with Tata wires during those times.

In the last two decades, Systematic has grown exponentially but more importantly, we have become the preferred supplying partner of all the major cable and conductor manufacturers in the country and this is our biggest accomplishment.

WCI: As the company has set up a new production facility – kindly share details about – the investment, infrastructure, product portfolio, kind of machinery, and manufacturing capabilities.

“We have become the preferred supplying partner of all the major cable and conductor manufacturers in the country and this is our biggest accomplishment.”

SA: Systematic has set up a massive new facility in Vapi, Gujarat on approximately18 acres of land. It is one of the largest manufacturing plants at a single location for cable armour wire and ACSR core wire that will set new benchmarks in quality and great cost savings for our customers, making Systematic the lowest cost producer of cable armour wire.

We have installed state-of-the-art machinery in this plant with a heavy emphasis on automation at every level. Major products to be manufactured here are cable amour—GI wire, ships, and ACSR core wire, and the ability to manufacture Jumbo coils of 2 MT.

Since the majority of the machinery has been imported for this plant, it can produce high-quality products in huge volumes at a cheaper cost for our customers.

The factory was supposed to start production in 2020 but due to the Covid situation, it will be commencing production by end of this year.

We have also invested heavily to make this facility high on sustainability through large solar plants for in-house power generation and also rainwater harvesting to save groundwater.

A unique feature of this ambitious plant is that despite being of its large scale, all the investment has been pulled from internal resources so that we can keep the plant debt-free and offer competitive prices to our customers.

“We have installed state-of-the-art machinery in the new plant with a heavy emphasis on automation at every level.”

WCI: What are the key strengths of the product range offered along with the certifications to testify its quality?

SA: At Systematic, we constantly strive towards how we can add value to our customers, especially cable and conductor manufacturers. We take pride in our strong work ethics and long-term relationships. The majority of our customers are 15 – 20 years old and the company has always stood by them even during difficult times.

In current times, most companies are facing multiple challenges with high volatility in steel prices which in turn impact their competitiveness.

GI wire is particularly a highly competitive product hence any company without proper cost control and economies of scale will struggle to survive in the longer run. Hence, it is very important for any cable/conductor manufacturer to have a reliable long-term steel supplier for consistent growth.

Because of the production efficiency of this factory, our customers can be assured of at least 5 – 10 percent cost saving only by virtue of consistent tolerance of sizes and large coil weights.

All products are BIS registered and ISO certified. Systematic wire guarantees minimum 20 percent longer life than other wires available in the market.

WCI: What are the different markets that the company serves with its product range? What are your plans with respect to expansion to newer markets and how do you view your prospects in the global market?

SA: The new project has been designed keeping global quality standards in mind and the factory has already been audited with some notable International clients.

We want this company to upscale the customer experience multifold. It is designed to be completely CUSTOMER CENTRIC and automated our entire sales process with the integration of high-end software such as SALESFORCE to give our customers a better service experience.

In the near future, Systematic will strongly rely majorly on cable and conductor manufacturers as large demand is expected from the Indian power sector.

WCI: Since the wire and cable industry is a direct beneficiary of the development in the power sector; what are your views on the developments taking place in the Indian power sector like the expansion and revamping of T&D?

SA: India is the third-largest producer of electricity in the world and second-largest consumer of electricity.

You will observe that while India is in the third position but there is a huge gap after the top 2. With the growing Indian population even if the power generation doubles we are still far from the top 2 nations.

Under the Union budget 2021-22 the government has allocated INR 305,984 crores for a revamp and reform new power distribution sectors scheme over the next five years.

We are therefore very bullish on this sector.

WCI: What are the emerging trends in the galvanized wire segment across the globe? Also, describe the prowess the company has to meet customer demands in the steel wires industry.

SA: In earlier times, the end consumers were not educated about galvanized wires. Any wire with white shine was considered galvanized and therefore all wires were the same for them.

But now with digitalisation the customer is far more aware and educated about GSM coating (i.e. gram coating per sq. mm of wire). They are willing to pay more for good quality, high GSM wire as they know that thicker coating will last much longer and will be much cheaper in the long run. Customers have also started asking for the salt spray test to identify how many years the wire will actually last after installation.

A lot of new innovations are coming up in the market as well such as the zinc alloy wire coating that increases the shelf life of the wire substantially. The aesthetic look of the wire has also become important. Customers require more shine and uniform coating. Zinc alloy coated wires will surely be in great demand in the coming years.

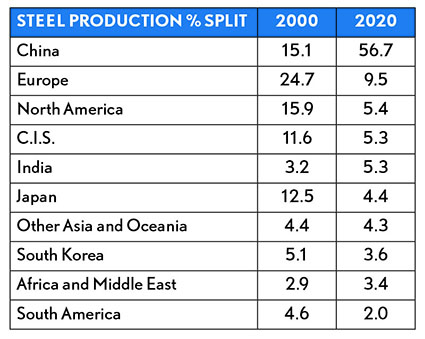

If you notice the trend, all countries have reduced their steel production except China, India, and Africa. This provides a good opportunity for Indian companies to be exporters in the long run.

“All the countries have reduced their steel production in the country except China, India, and Africa; this provides a good opportunity for Indian companies to be an exporter for the long run.”

WCI: In view of the crisis brought by the COVID-19 pandemic, what was the impact on the Indian wire industry and the disruptions brought in the supply chain and the demand? How did the Systematic Group adapt to the crisis?

SA: COVID 19 was a testing ground for everyone and the last 2 years have been difficult in general. No one imagined that all economic activities will come to such a standstill. Demand in the industry has dropped by 40 to 60 percent.

However, we have turned the corner. Things are starting to look in a positive direction and there will be a lot of accumulated demand in the coming times.

At Systematic, our employees’ safety was paramount during Covid times. We tried to support them in every way possible -safety protocols, vaccination camps, and most importantly moral support.

We stood by our employees during these challenging times and not a single rupee was deducted from anyone’s wages and salaries.

WCI: Moving ahead, what are the future plans of the company?

SA: At Systematic, ‘Innovation and Growing Together’ are our core mantras; therefore both these areas are under the close leadership of my Father Mr. Rajendra Agrawal.

Constant innovation and robust R&D sector are critical to stay relevant and he consistently invests his time to be able to better our quality, offer better cost-effectiveness, and superior service experience to our customers.

We also believe that growth should be for all and philanthropy is a very important aspect of it. Every year, a percentage of our profit is channelised towards various CSR activities and causes we strongly believe in. After all, one thing we can certainly learn from Covid– humanity is above all.

We are not in the race to become number one in the industry. We believe in delivering value to our customers and will continue to serve them for years to come.