“The group was founded on our management’s vision of making world class products available to Indian customers at a reasonable rate.”

Stanvac-Superon Group is one of the largest manufacturers and exporters of high-quality welding consumables, protective coatings, and stainless steel wires. Superon was incorporated in 1994 with the commissioning of its first welding electrode production unit. The group aims to make world-class products available to the customers at a reasonable rate. Wire & Cable India recently interviewed Mr. Sharad Mehra, Commercial Director, Stanvac-Superon Group, wherein he dives into the product portfolio and recent developments of the company.

Wire & Cable India: As one of the largest manufacturers, exporters, and suppliers of industrial repair and maintenance solutions, Superon Group has diversified into various industries with time, could you please enlighten us on the business journey of the Company while charting out the key achievements?

Sharad Mehra: Superon Group, established in 1994, is one of India’s largest manufacturers and exporters of industrial repair and maintenance solutions. The group was founded on our management’s vision of making world class products available to Indian customers at a reasonable rate. Following this principle, Superon Group has made a mark in India. It has also been successfully exporting its products to over 70 countries.

“We are intending to establish the manufacturing unit of stainless steel flux core wire by 2023.”

WCI: Kindly outline the product portfolio of the company, with particular emphasis on the welding wires and stainless-steel wires segment. Also, highlight the key features of the product range.

SM: Our welding products range includes:

- MS Stick Electrodes & Wires (E6013/E7018/E7018-1/E7016/E7016-1/ER70S6)

- SS Stick Electrodes & MIG/TIG Wires (S308L/309L/316L/310/347/318//385/312/2209/2594 etc.

- Low Alloy & Nickel Based Electrodes (E7018G/7018A1/8018G/9018G/8018B2/9018B3/9018M/10018G/10018D2/11018M/NiFe/NiCrMo3 etc.)

- Hard facing stick electrodes

- Maintenance and repair grade welding consumables

- Stainless steel pickling products/flaw check DPT kits/welding anti-spatter sprays

Our stainless steel wire segment includes the following range of products:

- Stainless steel wire for general application

- Fine wire in size ranging from 0.10 mm up to 0.79 mm

- Thick wire with size ranging from 0.80 mm up to 10.00 mm

- Spring wire

- Electro polish quality wire

Most common grades are AISI 304/302, 316, 309, 321, 314 and many more.

WCI: Could you please talk about the core capabilities of the company – with regard to manufacturing capacity and also the infrastructure of the manufacturing units? Has there been any upgradation of the manufacturing plant in the recent past or do you plan to do so in the future?

SM: We have three plants with an installed capacity of 1400 MT for stainless steel non-welding wire, stainless MIG/TIG/SAW wire, fine wire, and 2000 MT for coated electrodes (stainless steel and mild steel electrode) and 800 MT installed capacity of copper-coated wire.

Our new division is industrial aerosol products, like DPT, anti-spatter, multi-purpose spray, multipurpose spray, zinc spray, etc.

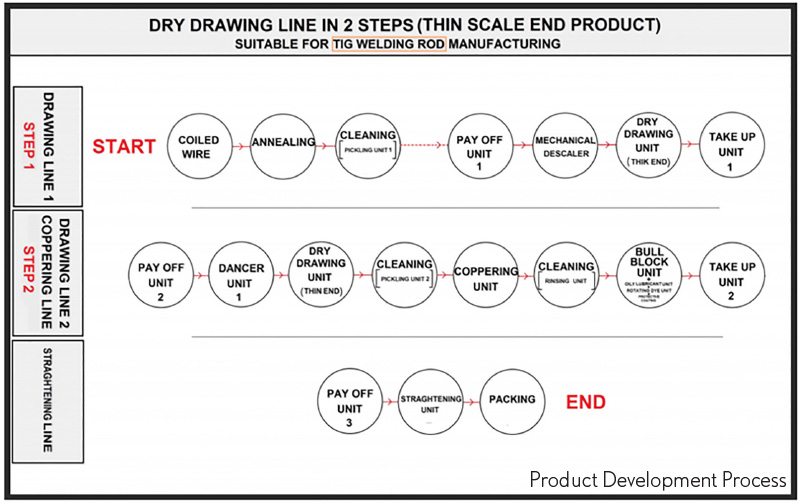

WCI: With a vast product portfolio, Superon has distinct expertise in manufacturing welding consumables, innovative repair and reclamation welding alloys and non-welding wires, could you please take us through the product development process for the welding wire segment?

SM: Above is the flow chart of our product development process.

WCI: Could you please shed some light on the various approvals and certifications the company has attained for its product range?

SM: Our company has acquired certification and approvals from TÜV Rheinland, Bureau Veritas, CE Approval, ABS Approvals, Lloyds (LRS Approval Certificate), DB Certificate, CWB (Canadian welding Bureau), NAKS Approval and Kuwait Oil Corporation Approval.

Some of the most common grades offered under above listed approvals are ER 308L/Lsi, 309L/Lsi, 316L/Lsi, ER 347Lsi, E 308L-16, E 6013, E 7018, ER 70S-6, E309L-16, E 316L-16, 6010 and many more.

WCI: As one of the largest manufacturers of stainless-steel welding consumables, and a prominent manufacturer of flux cored wires, do you think the Indian welding wire industry is on par with the international countries? Also, what is the current market size of the industry and your projections for its growth in the coming times?

SM: In view of the current market demand of flux cored wire in the domestic and international market, we are intending to establish the manufacturing unit of stainless steel flux core wire by 2023.

WCI: What kind of advancements has been brought about in the welding technology segment at your company? Also, how do you ensure the maintenance of quality in your welding wire range of products?

SM: Surface conditions play key roles in filler materials, in view of that, we have installed the ultrasonic cleaning system in our process which has given better surface cleaning. It delivers better weldability.

WCI: Could you please shed some light on the cable coating range offered by the company and also delve on the features of the products?

SM: We have developed an innovative and unique product to prevent the fire from electrical cables — FIREX EC-43, a water immersion/weather resistant intumescent fire protection coating for combustible electrical & communication cables.

WCI: Has there been any recent development at Superon Group that you wish to highlight? Going ahead, what are the plans of the company to achieve further growth in the market?

SM: Yes, we keep adding new products in our welding manufacturing range. In recent times, we have added ER 70S-6 copper coated wire. Moving ahead, the company is looking to add few more products in welding basket to be recognized as the only company from India with full range of welding consumables or to be called as one-stop welding company of India.

“Superon Group is looking to add few more products in welding basket to be recognized as the only company from India with full range of welding consumables.”