By all account, the solar power generation in India has seen an unforeseen rise in the previous few years, creating enormous demand for generation and transmission related technologies, equipment, and product, not to mention special kind of wires and cables suitable to solar energy.

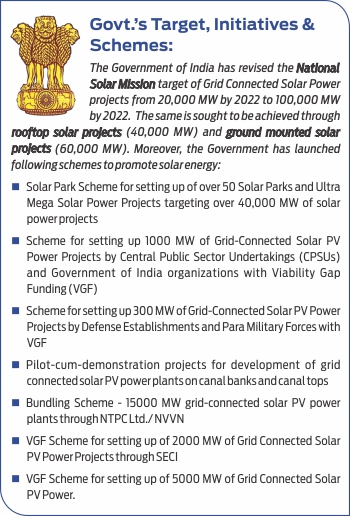

India is on a roll in renewable energy generation, especially the solar power. The country’s solar grid’s cumulative capacity reached 13.65 GW as of 31 July 2017. During May 26, 2014 – March, 31, 2017, India quadrupled its solar-generation capacity from 2,650 MW. The Government of India has revised the National Solar Mission target of Grid Connected Solar Power projects from 20,000 MW by 2022 to 100,000 MW by 2022 along with USD 100 billion investment target. The same is sought to be achieved through rooftop solar projects (40,000 MW) and ground mounted solar projects (60,000 MW).

About 3.01 GW of solar capacity was added in 2015-2016 whereas the year 2016-2017 saw the solar capacity addition of 5.525 GW, the highest in a year so far. Moreover, the new capacity addition for 2017-18 is expected to touch 8.8 GW, a rise of 76 percent over 2016 and making India the third biggest solar market worldwide. With this kind of surge in solar power generation in recent years and a flurry of initiatives to reach the mark of 100 GW by 2022, there has been a never-seen-before growth in demand of solar power technologies and electricals for the harvest, storage, and transmission of solar energy.

About 3.01 GW of solar capacity was added in 2015-2016 whereas the year 2016-2017 saw the solar capacity addition of 5.525 GW, the highest in a year so far. Moreover, the new capacity addition for 2017-18 is expected to touch 8.8 GW, a rise of 76 percent over 2016 and making India the third biggest solar market worldwide. With this kind of surge in solar power generation in recent years and a flurry of initiatives to reach the mark of 100 GW by 2022, there has been a never-seen-before growth in demand of solar power technologies and electricals for the harvest, storage, and transmission of solar energy.

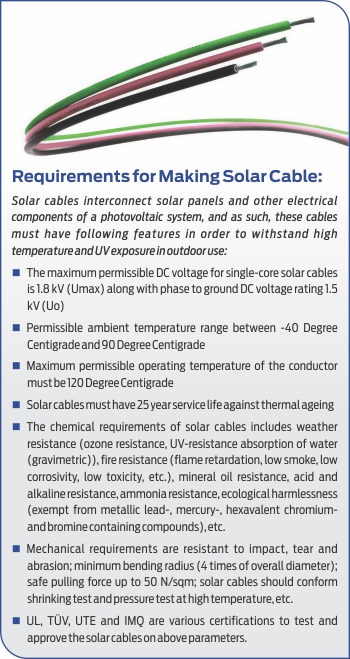

Cables are the only medium to transmit power and the specific cabling requirements for solar energy transmission has also seen quite a growth inspiring cable companies to meet critical specifications. In both the technology domains, viz. solar photovoltaic technologies and solar thermal power plants, the choice of solar cables is critical as low efficiency, overheating, longevity problems (minimum life should be 25 years), and technical cabling losses have to be eliminated in such cables. E-beam cross-linking, special purpose compounding solutions (for sheathing and insulation), good conducting material, rigorous testing, and authentic certifications are some of the norms being followed by companies specializing in solar cables.

WCI recently conducted a series of interview of various stakeholders in the manufacture of solar cables including manufacturers, compounders, and technologists in order to canvas the trends with regards to solar cable making in their respective domains. For your read:

_______________________________________________________________________________

Uniflex Cables Ltd. (Now the Cable Division of Apar Industries Ltd.)

Uniflex Solar Cables in Most of

Prestigious Solar Projects in India

“We at Apar have set up two (2) electron beam (EB) accelerators for

cross linking of polymers used for insulation and jacketing of these solar DC cables for

connecting solar panels to ensure its life over 25 years,”says Mr. V.K. Bajaj, COO, Uniflex Cables Ltd.

Wire & cable India: What was the reason behind venturing in to solar cables?

V. K. Bajaj: The world is moving towards reducing the carbon emissions, and Govt. of India has taken it quite seriously. The Govt. of India has set up a very ambitious plan to commission 175 GW of renewable energy generation by 2022. This includes installations of about 100 GW of solar power generation systems. Fortunately, the cost of setting up solar projects has come down significantly over the last few years, thereby making it easier to realize these targets.

V. K. Bajaj: The world is moving towards reducing the carbon emissions, and Govt. of India has taken it quite seriously. The Govt. of India has set up a very ambitious plan to commission 175 GW of renewable energy generation by 2022. This includes installations of about 100 GW of solar power generation systems. Fortunately, the cost of setting up solar projects has come down significantly over the last few years, thereby making it easier to realize these targets.

Cables are an important component of any solar projects. We at Apar realized the business potential in this segment and have prepared ourselves to support this initiative of the Govt. The Solar projects are expected to have a minimum life of 25 years and therefore to make the projects bankable, the components used for solar projects should support this life of over 25 years.

Over the last few years, our cables have been used in most of the solar projects in India, making us one of the largest vendors in this segment. List of our customers include Tata Power Solar, Azure, Welspun, Acme, Lanco, Schneider, ABB, GE, L&T, Vikram Solar, Warree, Harsha Abekus, Suzlon, Gamesa, Hero, Mahindra Susten, Sterling Wilson, Adani, Greenko, Juwi, Enerparc, Hartek, Amplus, Ujaas, Refex, Chemtrol, SolaireDirect, Enrich Energy and many more. We are also exporting our cables to the largest 1200 MW solar plant being set up in Abu Dhabi by ADEWA besides large projects in Morocco and in Latin America.

WCI: Tell us about your product range with regard to solar cables. What kind of features does your product have?

VKB: We offer almost all types of cables used for solar projects and that includes solar DC cables, LT XLPE DC cables, LT XLPE AC cables, LT XLPE and PVC insulated control cables, medium voltage XLPE cables up to 33 KV, high voltage 66 KV cables, RS 485 communication cables, fiber optic cables, ACSR/AAAC bare and insulated overhead conductors.

VKB: We offer almost all types of cables used for solar projects and that includes solar DC cables, LT XLPE DC cables, LT XLPE AC cables, LT XLPE and PVC insulated control cables, medium voltage XLPE cables up to 33 KV, high voltage 66 KV cables, RS 485 communication cables, fiber optic cables, ACSR/AAAC bare and insulated overhead conductors.

We at Apar have set up two (2) electron beam (EB) accelerators for cross linking of polymers used for insulation and jacketing of these solar DC cables for connecting solar panels to ensure its life over 25 years. We also offer EB cross linked 105 Deg C rated LT XLPE cables for DC and AC applications and also offer medium voltage 105 Deg Celsius rated XLPE cables with special insulation compound. All these can offer trouble free service for over 25 years cable life. We have also developed rodent resistant solar DC cables to reduce O&M costs. We also have solar DC cables with integrated HDPE duct, so that there is no need to put these cables in an external Duct.

WCI: What are the key factors driving the Solar Cables market? What will be the market size and the growth rate in the coming years?

VKB: As already mentioned that to meet the Govt. objectives, lots of solar projects are being set up in India. Besides the ground mounted utility scale solar projects, lots of initiatives are being taken to promote roof top projects. During FY17, about 5.5 GW solar projects were commissioned, whereas, during FY18, about 8.5 GW projects are expected to be commissioned, and in coming years, perhaps 10-11 GW per year or more. Besides the domestic demand, Indian EPC contractors are well sought after by International customers because of lower costs and lot of experience, hence there will be lot of upside for Indian cable products for exports.

WCI: How do you foresee the evolution of solar power generation in India? What are the key growth factors and challenges for the same?

VKB: Earlier, few years ago, the solar power generation costs were quite high and its tariff used to be over Rs 10 per unit, which started coming down gradually. As the cost of setting up solar projects has come down and bids are being received at below Rs 2.5 per unit, it seems the most competitive option available compared to wind power (Rs 3.4-3.5 per unit) and thermal power generation even costlier. The time frame to set up solar projects is much less compared to other methods of power generation. Therefore, solar project installations are expected to continue for few years. The disadvantage is that this solar power generation is during day time only for 8 hours for about 300 days in a year. Hence it will be prudent for Govt. to also continue, in a limited way with wind power and thermal power and other means like hydro and nuclear etc.

There are reports that the solar panel costs are hardening and it could hamper the current situation of solar power competitiveness. Impact of GST could also be impacting the costs, as in pre GST period these projects were enjoying excise duty exemptions. There is far too much volatility in copper and aluminium leading to increased costs. The funding of solar projects is also getting restricted to some extent, and the solar developers are finding it difficult to make timely payments to their vendors especially cable suppliers. There are issues with some of the State Discoms not honoring the PPA’s already signed and the transmission lines for power evacuation is also becoming an issue. So these are the challenges that need to be overcome.

_______________________________________________________________________________

Havells India Ltd.

Havells, a part of Green Energy Drive Through Manufacturing Solar cables

“Lots of developments are done by Havells towards suitability of solar cables under toughest application such as highest resistance against environment like U.V., ozone and humidity; suitability of cables under extreme temperature (-40°C to 120°C); suitability in toughest weather condition; high resistant to abrasion, impact, tear and pressure,” says Mr. Sumeet Vyas, Senior General Manager, Havells India Ltd.

Wire & Cable India: What was the reason behind venturing in to solar cable?

Sumit Vyas: As we are aware that majority of electricity in India is being generated through fossil fuels like coal, diesel and natural gases. With the use of fossil fuels, there are number of challenges which are becoming a serious concern such as rising price of fuels, limited resources, import dependence and other serious environmental issues.

Sumit Vyas: As we are aware that majority of electricity in India is being generated through fossil fuels like coal, diesel and natural gases. With the use of fossil fuels, there are number of challenges which are becoming a serious concern such as rising price of fuels, limited resources, import dependence and other serious environmental issues.

Solar power as a renewal energy has grown up significantly in the past few years and considered as only solution for future energy needs. The economical viability, reliability, and reachability with minimum life cycle cost are main advantages in solar power segment. Efficiency optimisation in electric network would be of prime requirement and needless to say that cables are lifeline for solar electric network for interconnection of various P.V modules.

Havells India Limited is also a part of this Green Renewable Energy Drive and involved in manufacturing of quality solar cable in the country with TUV product certification.

WCI: Tell us about your product range with regard to solar cables. What kind of features does your product have?

SV: Havells India Limited is manufacturing various kinds of solar cables which are required to interconnect the solar modules, string arrays, array junction boxes up to the inverter in D.C voltage circuit and A.C. armoured cables from inverter output to the transformer grid within solar network.

Havells has developed solar cables with low smoke halogen-free, flame retardant crosslinked insulation and outer sheath range from 1.5 sqmm to 1000 sqmm. Such cables can perform under extreme condition of installation and toughest weather conditions. The compliance of cable for UV resistant according to HD 605/A1 reasonably demonstrates ‘withstand capacity’ of cable for long term exposure to sunlight.

Lots of developments are done by Havells towards suitability of solar cables under toughest application such as highest resistance against environment like U.V., ozone and humidity; suitability of cables under extreme temperature (-40°C to 120°C); suitability in toughest weather condition; high resistant to abrasion, impact, tear and pressure. HAVELLS PV cables developed to perform efficiently and safely for years to come. Our solar cable has obtained product certification from TUV standard -2Pfg 1169/08-2007 standard, which is professional stamp of quality for solar cable worldwide.

Lots of developments are done by Havells towards suitability of solar cables under toughest application such as highest resistance against environment like U.V., ozone and humidity; suitability of cables under extreme temperature (-40°C to 120°C); suitability in toughest weather condition; high resistant to abrasion, impact, tear and pressure. HAVELLS PV cables developed to perform efficiently and safely for years to come. Our solar cable has obtained product certification from TUV standard -2Pfg 1169/08-2007 standard, which is professional stamp of quality for solar cable worldwide.

WCI: What are the key factors driving the Solar Cables market? What will be the market size and the growth rate in the coming year?

SV: The Govt. of India has taken targets of 100 GW of solar renewal energy by the end of year 2022. Till date we have been able to set up approx. 14 GW Solar power energy plants in the country.

There is a long way to go. The expected growth in the year 2017 would be around 12 GW. The target is very ambitious and we are ready to take it forward. The expected volume of solar cables would be around 3000 Crore/annum. Havells is well in pace to ramp up its production capacity to enhance substantial market share in the country.

The availability of insulating material at reasonable prices in India would be key driving factors in the solar cable market besides clear cut understanding of guidelines for setting up technical Standard as per Indian climatic and operating conditions. Import substitution of XLPO compound may be another driving factor for solar cable market.

WCI: How do you foresee the evolution of solar power generation in India? What are the key growth factors and challenges for the same?

SV: The Global Solar Market is expected to reach approx. 550 GW within next 5 years. The Govt. of India foresees very optimistic growth in solar power generation in coming future. Cumulative growth is expected to reach up to 100 GW in next 5 years. After China and U.S.A., India shall become biggest market in the segment.

The key growth factor in India would be development and technological innovations in solar energy along with economical viability with Govt. support. The major challenge on the other hand is higher prices of PV Modules. Import substitution for P.V. modules/components in India is of prime requirement for making economical feasibility of solar power generation. T&D losses are higher as compared to other power generation source along with complex formalities for land acquisition and grid connection.

_______________________________________________________________________________

Paramount Cables

Offering Full Range of Solar Cables

“Paramount offers TUV certified electron beam cross linked solar cables. E- Beam irradiation is a process in which the polymer is exposed to a highly charged stream of electrons that creates cross linking between the molecules. This cross-linking significantly improves thermal, mechanical and chemical properties of the polymer,” informs Mr. Parth Aggarwal, Director, Paramount Cables.

Wire & Cable India: What was the reason behind venturing in to solar cables?

Parth Aggarwal: We are living in a time where the world around us is changing rapidly. Climate change is a reality and main cause of this is the extravagant use of traditional fossil fuels worldwide. This has also led to severe depletion of our fossil fuel reserves. Hence we have no choice but to shift our focus to the development and harnessing of renewable sources of energy. Solar power is the most widely accepted and cost effective way to go forward. Today, India itself is investing hugely into solar power to make it one of the major backbones for our energy needs. Paramount has always laid a great emphasis on manufacturing environment friendly cables and wires. Therefore, solar cable was an obvious choice- a venture that has future and a cause.

Parth Aggarwal: We are living in a time where the world around us is changing rapidly. Climate change is a reality and main cause of this is the extravagant use of traditional fossil fuels worldwide. This has also led to severe depletion of our fossil fuel reserves. Hence we have no choice but to shift our focus to the development and harnessing of renewable sources of energy. Solar power is the most widely accepted and cost effective way to go forward. Today, India itself is investing hugely into solar power to make it one of the major backbones for our energy needs. Paramount has always laid a great emphasis on manufacturing environment friendly cables and wires. Therefore, solar cable was an obvious choice- a venture that has future and a cause.

WCI: Tell us about your product range with regard to solar cables. What kind of features does your product have?

PA: Paramount offers TUV certified electron beam cross linked solar cables. E- Beam irradiation is a process in which the polymer is exposed to a highly charged stream of electrons that creates cross linking between the molecules. This cross-linking significantly improves thermal, mechanical and chemical properties of the polymer. Paramount offers full ranges of solar cables sizes starting from 2.5 sq mm to 95 sq mm. Paramount solar cable XLPO offers higher performance in extreme environment.

WCI: What are the key factors driving the Solar Cables market? What will be the market size and the growth rate in the coming years?

WCI: What are the key factors driving the Solar Cables market? What will be the market size and the growth rate in the coming years?

PA: The Government of India has an ambitious target of 100 GW by 2022 because of which Indian solar market is growing swiftly. As this sector grows, developers are now taking serious steps than ever before attracting worldwide investment. Both government and private sectors are making an extra effort to ensure the goal of 100 GW by 2022. On a conservative side, a 200 MW solar project uses approx. 10000 km of solar cable. India this year is expected to add up about 10 GW to its capacity. Hence, we can expect the solar cable requirement for this year in India alone to be in excess of a huge 500,000 km. The key factors for the solar cable industry particularly are quality, approvals as well as prices. Competition from Chinese industries is a huge challenge as inferior quality modules and other equipment available at low prices are flooding the Indian market. However, most projects go through extensive quality approvals so we are confident that these challenges can be met and overcome.

WCI: How do you foresee the evolution of solar power generation in India? What are the key growth factors and challenges for the same?

PA: As I said above, India targets 100 GW of solar capacity by 2022. With the growth in infrastructure development, implementation of large-scale solar project through solar park models and increasing installation roof top projects, the industry is set to grow at a high pace for the next few years. Solar power would emerge as one of the most critical power sources for India. In 2017 only, we are expecting to add up approx. 10 MW to our solar capacity that would make us the third largest solar market in the world.

However, amid this positive scenario there exist many challenges as well. The tariffs per unit are falling rapidly limiting the recovery of investments that make future investors wary and can possibly lead to a slowdown in these projects. The uncertainty in government policies regarding subsidies and anti dumping duties on imports as well as state elections creates roadblocks in the smooth growth.

Other key growth factors for acceptance of solar power would be the education and the understanding of the harmful effects of excess use of fossil fuels and involvement of the government in the field of solar power generation. The Jawaharlal Nehru National Solar Mission is one of the key projects, which will open many doors for new startups and entrepreneurs and many more MSME’s.

_______________________________________________________________________________

Advance Cables Technologies (P) Limited

Suitable Solar Cables for Indian Solar Projects

“The product durability is up to 30 years under tough external conditions. In terms of outdoor durability, it can resist extreme temperatures (-40°C to 120°C maximum at the core) and ozone rays,” says Mr. Nikhil Kumar Reddy, Design and Development Engineer, Advance Cables Technologies (P) Ltd.

Wire & Cable India: What was the reason behind venturing in to solar cables?

Nikhil Kumar Reddy: Solar photovoltaic is now, after hydro and wind power, the third most important renewable energy source in terms of globally installed capacity.

Nikhil Kumar Reddy: Solar photovoltaic is now, after hydro and wind power, the third most important renewable energy source in terms of globally installed capacity.

WCI: What kind of features does your product have?

NKR: We are manufacturing solar cables up to 240 sq mm and we have a certification from TUV Rehinfield. The voltage ratings of our solar cable are 1.5 (1.8) KV DC/0.6/1.0 (1.2) KV AC. The product durability is up to 30 years under tough external conditions. In terms of outdoor durability, it can resist extreme temperatures (-40°C to 120°C maximum at the core) and ozone rays. The cables are UV resistant, halogen free (low smoke emission and low toxicity/corrosivity during fire), flame/fire retardant, and flexible enough for fast and easy installation. Also, our solar cables are fully recyclable in accordance with new environmental regulations. Furthermore, the installation is easy with color identification (black/red), which is suitable to common connector types. Lastly, the cables are weather resistant too, with resistance towards mineral oils, acids and alkaline.

WCI: What are the key factors driving the Solar Cables market? What will be the market size and the growth rate in the coming years?

NKR: Solar cable is the interconnection cable used in photovoltaic power generation. A solar cable interconnects solar panels and other electrical components in the photovoltaic system. Due to huge demand for solar power, there will be great demand for solar cables too in the coming years.

_______________________________________________________________________________

Ultracab (India) Limited

Full Range Solar Cables

“Currently, we have complete range of solar cables as per three different standards. Out of three, two cable standards are Indian and these cables are made keeping in mind the Indian weather conditions,” says Mr. Niteshbhai Vaghasiya, CMD, Ultracab (India) Limited.

Wire & Cable India: What was the reason behind venturing in to solar cables?

Niteshbhai Vaghasiya: Govt. of India has decided to generate solar power 100 GW before end of year 2022. Due to this huge requirement, demand for solar cable will occur immensely within next 4 year.

Niteshbhai Vaghasiya: Govt. of India has decided to generate solar power 100 GW before end of year 2022. Due to this huge requirement, demand for solar cable will occur immensely within next 4 year.

WCI: Tell us about your product range with regard to solar cables. What kind of features does your product have?

NV: Currently, we have complete range of solar cables as per three different standards. Out of three, two cable standards are Indian and these cables are made keeping in mind the Indian weather conditions. The third is German standard, which is prepared considering the use of the cable in extreme weather conditions. The cables are extremely good for aimed applications; and the life of the cable is up to 25 years.

WCI: What are the key factors driving the Solar Cables market? What will be the market size and the growth rate in the coming years?

NV: From our point of view, key factor for driving the solar cables market is rapidly growing solar power market. India has done wonders in solar power generation in the last few years to the extent of lowering the solar power tariff to a surprising Rs 2.44/ unit of electricity. Although I can’t exactly say what would be the market size of the solar cables, the market would be growing in proportion to the solar power generation growth, and if we go by the 2022 target, it would be huge.

WCI: How do you foresee the evolution of solar power generation in India? What are the key growth factors and challenges for the same?

NV: Due to the Govt. policy orientation with regards to solar power generation and considering the last few year’s data of installation of solar plants, this has been the fastest growing industry in the financial year 2016-17, and according to us, it continue to be one of the fastest growing industries in times to come.

As I just said, the key growth factor will be cost of generation which is lower than coal fired power plants. Also, the payback period is much better than other renewable energy sources. The challenge of course will be the land availability. Solar plants require lots of land to achieve 100 GW by year 2022. Thus, it will be difficult a little in that perspective.

_______________________________________________________________________________

Shakun Polymers Ltd.

Solar Cable-Specific Insulation and Sheathing Materials

“Neglecting correct wiring and using material that is not suitable for solar applications can compromise the overall lifetime of a system/project,” says Anirudh Bansal, Business Development, Shakun Polymers Ltd.

Wire & Cable India: Tell us about the special compounds used in the manufacturing of the solar cables.

Anirudh Bansal: There are various types of insulation and sheathing materials used for the conductors of solar cables and wires; commonly used are cross-linked polyolefin (XLPO) and cross-linked polyethylene (XLPE).

Anirudh Bansal: There are various types of insulation and sheathing materials used for the conductors of solar cables and wires; commonly used are cross-linked polyolefin (XLPO) and cross-linked polyethylene (XLPE).

WCI: What are the properties of compounds used in solar cable manufacturing?

AB: Commonly, solar cable and wire properties are determined by their cable-specific insulation and sheathing materials. When exposed to irradiation, the molecular structure of cable material can change. To qualify for use in PV power applications, the insulation and sheath material of solar cables and wires must meet several crucial requirements, including weather- and UV-resistance.

As solar cables lay usually outdoors and are subject to direct sun radiation and air humidity, it should withstand high and low temperatures and thus be usable within a temperature range of usually between -40°C to 90°C. Also, it should bear mechanical stress from pressure, bending or stretching experienced during installation and be resistant to abrasion. Thus, most sheaths are made up of plastics cross-linked using electron beam to withstand chemical stress in form of acids, alkaline solutions and salt water.

As solar cables lay usually outdoors and are subject to direct sun radiation and air humidity, it should withstand high and low temperatures and thus be usable within a temperature range of usually between -40°C to 90°C. Also, it should bear mechanical stress from pressure, bending or stretching experienced during installation and be resistant to abrasion. Thus, most sheaths are made up of plastics cross-linked using electron beam to withstand chemical stress in form of acids, alkaline solutions and salt water.

WCI: How do you educate and support your customer?

AB: The quality, safety, and profitability of a solar plant or project depend on the workmanship and the efficiency of its components like PV modules, inverter, wiring etc. Neglecting correct wiring and using material that is not suitable for solar applications can compromise the overall lifetime of a system/project. Proper selection of wires and cables are crucial in the long-term with low-quality cables resulting in higher maintenance costs.

Shakun’s responsive marketing network helps in understanding its customers’ needs and come up with appropriate cable application compounds. Uncompromising quality, consistent performance, safe production practices and a holistic service infrastructure has helped the company to attain a good share in domestic as well as international markets.

WCI: What capabilities are required for manufacturing compounds for solar cables?

WCI: What capabilities are required for manufacturing compounds for solar cables?

AB: There are a lot of cable specific challenges a compound has to pass for use in photovoltaic applications. Firstly, there are lists of important standards for solar cables and wires which specify certain quality requirements for the insulation and sheathing materials of which they are made of. Secondly, the desired properties as discussed have to be considered which would affect the performance of these cables. Solar cables require a very unique type of polymers/compounds to meet all specifications and address all property requirements. Similar care has to be taken while processing such polymers, tandem extrusion is recommended in processing of such polymers for retaining all its properties.

There is no ideal compound which exists in today’s world. The challenge would be to find the right balance between properties and processability. Cross-linking is a widespread method in the cable industry. Cross-linked materials today are being considered as the ideal compound for solar industry and are gaining more and more market share.

WCI: What do you think about the solar cable market and its demand in the near future?

AB: Solar cable industry is estimated to grow in the future owing to the governments targeted spend on the renewable energy sector. At present solar cable manufacturers are facing difficulties in balancing out of pocket expense with long term reliability while continually meeting evolving requirements and trends from developing cables for newer technologies, to meeting more stringent fire ratings, test methods, UL and CSA standards, National Electric Code requirements, and global standards for halogen-free, fire-retardant, and low-corrosive gas emissions.

Demand for solar power is rapidly growing with various installations coming up on roof tops, parking lots, highways and due to governments’ special incentives to promote such installations. No matter what the size and the number of installations, all PV application require high-quality cabling with good sheathing and insulation that provide excellent mechanical properties and superior sunlight resistance for outdoor installations, flame-resistance for added safety, and flexibility for easy handling.

_______________________________________________________________________________

AEI Compounds India Pvt. Ltd. (Bihani Group)

Special Compound System as per the Expectations of PV Insulation and Sheathing

“For solar cables, we provide a special compound system SX-0650:CM601, which is UV resistant, silane crosslinkable, halogen free, flame retardant, and flexible compound for use in single core photovoltaic cables,” says Mr. Saurabh Bihani, Director, AEI Compounds India Pvt. Ltd.

Wire & cable India: Tell us about the special compounds used in the manufacturing of the solar cables.

Saurabh Bihani: We provide a special compound system SX-0650:CM601 which is as per the expectations of photovoltaic insulation and sheathing.

Saurabh Bihani: We provide a special compound system SX-0650:CM601 which is as per the expectations of photovoltaic insulation and sheathing.

WCI: What are the properties of compounds used in solar cable manufacturing?

SB: SX-0650:CM601 is UV resistant, silane crosslinkable, halogen free, flame retardant, and flexible compound for use in single core photovoltaic cables. The graft component SX-0650 (natural and UV stabilized) is blended with cross-linking catalyst master batch CM601 generally in a ratio of 95:5. The SX-0650:CM601 system has been developed to meet the requirements for cables for PV systems TUV 2 Pfg 1169/08.2007 and new European Standard EN50618.

WCI: How do you educate and support your customer?

SB: The standard application of solar system compound is still quite unknown to the cable manufacturers even though lot of trading is on. As we have achieved global experience through SACOAEI about the processing, testing and other measures/procedures, we are able to provide all support to our customers.

WCI: What capabilities are required for manufacturing compounds for solar cables?

WCI: What capabilities are required for manufacturing compounds for solar cables?

SB: For processing, HF screw is required with a well equipped quality testing lab.

WCI: What do you think about the solar cable market and its demand in the near future?

SB: The market was growing fast and well sometimes back but now the growth has slowdown may be due to GST application or because of the dull months of the year. The demand for solar cable in future is definitely bright as this specific movement has been supported by all – government, concerned authorities, and common people. There is no alternate to electricity as good as solar. Of course, the requirement in the coming days is simply unlimited.

_______________________________________________________________________________

Rosendahl Nextrom

Extrusion Technology for Production of Single and

Multi-Core Solar Cables

“Our experience has shown the utmost results and we are happy to assist with individual solution. The advantages the customer can get with Rosendahl co-extrusion are- thinner walls on solar cables, higher production speed, easy operation (as it is only one extruder group), lower investment costs and shorter line length,” says the Company.

Wire & Cable India: What are some crucial requirements for solar cable manufacturing?

Rosendahl: Renewable energy is booming. Not only single households, but more and more companies are also changing their power supply sources. Solar energy is one of these sources transmitted through solar cables. And these have special properties to fulfill environmental requirements. They need to be UV resistant, weather resistant and mechanically resistant, as well as offer electrical properties with an ideal lifetime of more than 25 years.

WCI: Is there some unique technology offered by Rosendahl for solar cables?

Rosendahl: We at Rosendahl deliver extrusion technology for the production of single and multi-core solar cables. The process covers insulation and jacketing in one production step on two extruders of a similar size. An optional stripe extruder can be included in the extruder group. The latest standard, TÜV2Pfg1169/08.07 or new European Standard EN 50618:2014, also allows the process to run co-extrusion (dual-layer extrusion with one crosshead).

Our experience has shown the utmost results and we are happy to assist with individual solution. The advantages the customer can get with Rosendahl co-extrusion are- thinner walls on solar cables, higher production speed, easy operation (as it is only one extruder group), lower investment costs and shorter line length.

Our experience has shown the utmost results and we are happy to assist with individual solution. The advantages the customer can get with Rosendahl co-extrusion are- thinner walls on solar cables, higher production speed, easy operation (as it is only one extruder group), lower investment costs and shorter line length.

WCI: Is the extrusion process for solar cables different requiring extra care?

Rosendahl: The extrusion process calls for intense product know-how. The material is typically a polyolefin copolymer which is then crosslinked using either an electron beam or the sioplas method to achieve the desired product quality. These two methods help the material attain a rigid molecular structure for chemical resistance and mechanical flexibility. The material characteristics can be tailored to suit custom needs.

_______________________________________________________________________________

Fainplast SRL

Convenient Compounds for the Production of Solar Cables

“The high skills developed in this demanding sector allow Fainplast to work in a very proactive way with a large number of reputable cable producers worldwide. Specifically in this product range, Fainplast has seen an increased demand for materials used in the production of photovoltaic cable.,” says Joshua Bruni, Exports Manager, Fainplast SRL.

Wire & Cable India: Tell us about your solar cable production capacity and introduce us to the product range.

Joshua Bruni: Fainplast is one of the world’s leading manufacturers of compounds for the cable industry. Its annual production capacity is more than 90,000 tonnes and product range includes PVC, LSZH, PP, PE and sioplas cross-linkable compounds that cover a big share of current cable manufacturers’ demand for plastics.

Joshua Bruni: Fainplast is one of the world’s leading manufacturers of compounds for the cable industry. Its annual production capacity is more than 90,000 tonnes and product range includes PVC, LSZH, PP, PE and sioplas cross-linkable compounds that cover a big share of current cable manufacturers’ demand for plastics.

WCI: What is the USP of your compounds used in solar cable manufacturing?

JB: In the last 15 years, the company has invested a lot in its range of sioplas cross-linkable LSZH compounds and has indeed experienced favorable outcome. Fainplast provides the most convenient and flexible solution for today’s market because it does not require big investments from the cable manufacturers. Besides the compounds can be produced in small lots and can be easy implemented on standard extruder lines making every cable producer totally independent.

WCI: What capabilities are required for manufacturing compounds for solar cables?

JB: Technical requirements for these types of cables and relative materials are very demanding. Despite being a halogen free solution, it is requested by standard EN 50618 and other international standards to be weather resistant and flame retardant with emission of low density smoke and low corrosive gases in case of fire. But the most important aspect is their long lasting performance in extreme ambient conditions. Such cables are certified for a 25 years lifetime in an operating temperature range of -40°C +90°C with 22.000 hours resistance at conductor peak temperature of 120°C. All materials are for this reason requested to be cross-linked and specialty stabilized to high temperatures.

JB: Technical requirements for these types of cables and relative materials are very demanding. Despite being a halogen free solution, it is requested by standard EN 50618 and other international standards to be weather resistant and flame retardant with emission of low density smoke and low corrosive gases in case of fire. But the most important aspect is their long lasting performance in extreme ambient conditions. Such cables are certified for a 25 years lifetime in an operating temperature range of -40°C +90°C with 22.000 hours resistance at conductor peak temperature of 120°C. All materials are for this reason requested to be cross-linked and specialty stabilized to high temperatures.

WCI: Has Fainplast been able to see the increase in demand for its solutions owing to solar energy sector’s growth?

JB: The high skills developed in this demanding sector allow Fainplast to work in a very proactive way with a large number of reputable cable producers worldwide. Specifically in this product range, Fainplast has seen an increased demand for materials used in the production of photovoltaic cables. A demand that in the early years was driven by the EU’s renewable energy policy and that recently has progressively moved to the Asian and African markets.

WCI: Tell us something about Fainplast’s testing process and certifications for its solar cable.

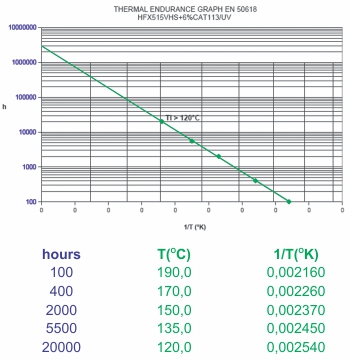

JB: Fainplast materials have all been tested in ageing ovens according to the Arrhenius thermal endurance method EN 60216-1 and EN 60216-2

(I will provide you a graph for reference) with a testing procedure that lasted several months. Results of these long tests have given Fainplast’s material specialists the figures to create mathematical equations that define the expected thermal performance of the materials even in a longer period of time and allow its customer to be relatively sure about the performance of the cable they are producing and delivering to the market.

_______________________________________________________________________________

Supermac Industries (India) Ltd.

High Speed Solar Cable Manufacturing Systems

Supermac is fully equipped to support the client for any extrusion need for solar cable manufacturing. There are dedicated and flexible manufacturing techniques based upon choice and productivity level of the client,” says Mr. Jasvinder Singh, Director, Supermac Industries (India) Ltd.

Wire & Cable India: Tell us about the main specifications of the solar cable extrusion lines.

Jasvinder Singh: Supermac has introduced the new high speed solar cable manufacturing system. We offer the lines in two configurations – tandem extrusion line and triple layer Co-extrusion. Both of these configurations are dedicated to different cable specification, viz. stripable and non-stripable.

WCI: Have you modified the extrusion lines for manufacturing the solar cables?

JS: Yes, we have developed new systems which are required for manufacturing solar cables. There are different types of solar compounds prevailing in the market depending upon the specification. We have engineered an extrusion machine, which can cater to almost all types of compounds. Beside that we have worked out on the system upgradation where the existing machine has been converted to a solar cable extrusion machine. These changes depend upon the extrusion model supplied to the customer with respect to the solar cables range that the customer wants to produce.

WCI: Kindly tell us about the technical parameters of the solar cable extrusion lines. Is the extrusion line suitable for all kinds of insulating wire or sheathing new energy source cables like solar cable?

JS: The typical solar cable extrusion line consists of payoff, extruder, cross head, capstan, and take up, depending upon the cable size and specifications. The extrusion elements designs are largely dependent on the compound to be used for solar cables. Even the extrusion line specifications depend upon the curing method selection. The e-beam cured cables slightly differ in design elements from the sioplas type cured cables.

WCI: What value proposition do you offer to your client in terms of technical capabilities, cost effectiveness, quality etc?

JS: Supermac is fully equipped to support the client for any extrusion need for solar cable manufacturing. There are dedicated and flexible manufacturing techniques based upon choice and productivity level of the client.

Our company shares its experience with the customers for extruding different cross linkable compounds, which other supplier cannot. The advance panel control system helps diagnosing the exact temperature of compound inside the barrel and creates such an interlock that the processing parameters starts to run under controlled conditions.

WCI: What do you think about the solar cable market and its demand in the near future in India viz a viz other countries?

JS: The solar cable is directly related to the solar electricity and distribution network system. The country is going through a phase where huge solar electricity generation plants are being installed. Once these plants are installed and commissioned, the total produced electricity will need huge cable network to distribute this generated energy. Of course, we foresee huge potential in solar cable demand in the coming years, but it all depends upon the government policies. The industry has already started to invest in solar projects creating huge need for solar cables. The favorable government policy can take this concept to each house hold sector, which can create huge demand for solar cables.