August 13, 2014

Highest quality control for various applications

SIKORA’s measuring devices are based on the latest optical techniques and X-ray technologies. For the various applications and requirements in production, both technologies contribute significantly to the online quality control during cable production when being used individually or in optimum combination.

LASER-technology for diameter and ovality measurement

For 40 years, SIKORA has been relying on the optical measuring method with CCD-technology. For 16 years, a combination of laser diodes as a light source with a CCD line and an intelligent analysing software has been used to measure online the outer diameter and the ovality of cables. The measuring principle is based on the diffraction analysis. Multiple points of an image are being used to calculate the diameter. This guarantees utmost accuracy and repeatability of the provided single values. The CCD-line technique is working without any moving parts, which means that one calibration prior to delivery is sufficient to guarantee lifelong precision of the device.

X-ray technology for diameter, ovality, wall thickness and eccentricity measurements

X-ray technology as an imaging method is mostly used for products for which not only the outer diameter should be measured but also the wall thickness and eccentricity of the cable. In 1993, SIKORA developed an X-ray measuring system with which it was possible to look into the cable and to measure precisely three wall thicknesses for the first time. With the X-ray measuring method, the cable is measured in real time during production to obtain all information. The X-ray technology is independent of influencing variables; for instance, the temperature of the measured product. Furthermore, a coupling medium is not required. This independence is especially the reason why X-ray technology is absolutely calibration free and an adjustment for changes in production requirements is not necessary; for example, the modification of the line speed and subsequent change in temperature. X-ray technology is suitable for quality control of all cable types, including rubber insulated cables as well as cables with textile reinforcement.

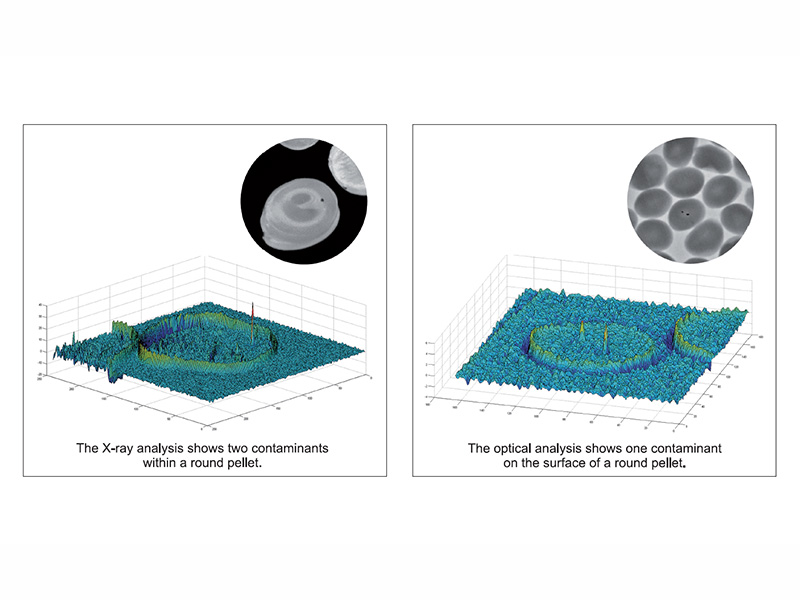

X-ray technology and optics to check the material’s cleanliness

The experience from over 20 years of measuring technology with X-ray and optical technology led to the development of an innovative control and sorting device for the quality control of XLPE-pellets, which combines the advantage of these two technologies. It allows the detection of metallic and organic contamination to 100 per cent. Impurities enclosed in the pellets can be found by using X-ray technology. In this manner, transparent as well as coloured (e.g. black) pellets and semi-conductive XLPE materials can be inspected for contaminants. By using an optical-measuring method, contamination on the pellet’s surface can be detected and sorted. The combination of the two technologies is unique and exceeds the performance of all previous solutions available on the market.