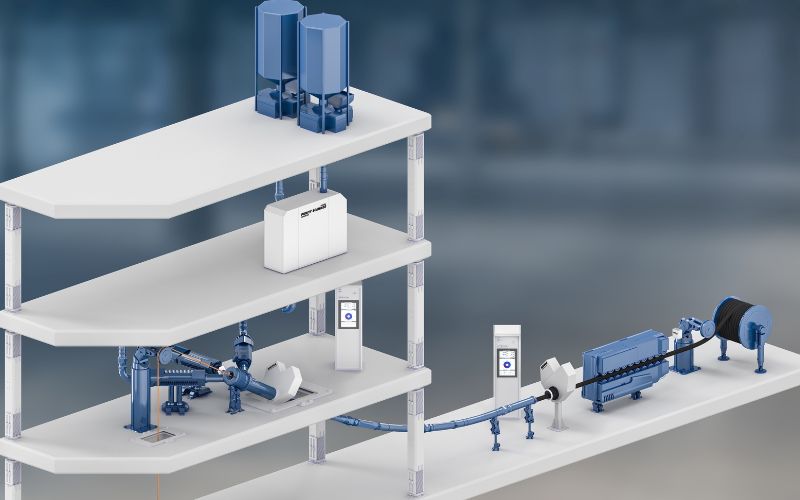

SIKORA has introduced the latest inspection and measuring technologies which monitor the plastic material for the insulation as well as the cable dimensions at crucial positions in the CV lines. From material purity and optimum melt temperature to precise monitoring of cable dimensions, the systems provide a comprehensive quality approach that ensures maximum reliability, safety and cost efficiency – all of which are indispensable for modern energy infrastructures.

Nov 13, 2024

A recent report identifies cable failures as one of the biggest challenges for offshore wind power in the future and predicts about 3,600 cable failures between 2024 and 2035, which could potentially cause costs of around EUR 61.5 billion. This makes it even more important to ensure the quality of these cable types at the highest level.

For this reason, SIKORA has introduced the latest inspection and measuring technologies which monitor the plastic material for the insulation as well as the cable dimensions at crucial positions in the CV lines.

The purer the XLPE material used, the lower the risk of cable breakdown and the higher the life expectancy of the cable. In particular, when manufacturing long cable length manufacturers aim at using as few cable connectors (joints) as possible, which is why material purity plays a crucial role.

Watch: Systematic Group

The PURITY SCANNER ADVANCED ensures seamless inspection as it inspects 100 % of the material for purity already before extrusion and automatically removes contaminated pellets, for example those with metallic impurities from 50 μm. This ensures that only high-quality, pure material enters the extruder.

Another crucial factor is the melt temperature of the XLPE material during extrusion. The right temperature ensures a homogeneous polymer melt and prevents premature cross-linking. This is where the ULTRATEMP 6000, which is used in the flow channel between the extruder and crosshead, plays a central role. It continuously measures the melt temperature, thus ensuring an optimum temperature and enabling an optimization in extruder output of up to 15 %.

Due to the optimized output of the ULTRATEMP 6000, the production length can be increased by up to 115 % before cleaning is necessary. This not only leads to higher efficiency but also reduces the number of cable joints – which optimizes both cable quality and costs.

Another SIKORA system used is the X-RAY 8000 ADVANCED, an X-ray measuring system that precisely records the dimensions of the cable, including wall thickness, eccentricity, diameter and ovality, directly in the CV tube.

Visualized in real time, the measured values enable quick centering of the extrusion tools and distortion-free control to the nominal dimension. At the end of the CV line, the X-RAY 8700 NXT measuring system also ensures precise measurement of the “cold values” of the cable.

Also Read: China’s Wuxi Huacheng Cable Enhances Quality Control of New Energy Cable Lines with SIKORA

In combination with the X-RAY 8000 ADVANCED at the beginning of the line, the shrinkage values for all three insulation layers of the cable can be precisely determined. Furthermore, the operator is shown whether the eccentricities of the individual layers and the ovality between the hot and cold measuring points have changed, which is important information during the cross-linking process in the CV tube.

Finally, the LM SMART length measurement system at the end of the CV line ensures that the required cable length is precisely maintained – a further contribution to quality assurance and resource conservation.

The intelligent integration of inspection and measuring systems along the entire CV line ensures the continuous quality of HV and EHV cables. From material purity and optimum melt temperature to precise monitoring of cable dimensions, a comprehensive quality approach ensures maximum reliability, safety and cost efficiency – all of which are indispensable for modern energy infrastructures.