August 30, 2014

Sai Extrumech Pvt. Ltd. has been developing its extrusion line technology for the last twelve years. Constant research and rigorous testing programmes have made Sai a world leader in the manufacture of precision extrusion line for mass production of high-quality plastic sheet. The combination of in-house testing and feedback of “in-service” machines has allowed Sai to develop extrusion line that both maximise machine efficiency and suit customer requirements. The original Sai extrusion line design for various materials (PP-PS-PET-ABS-Multilayer) has been extensively tested and is constantly upgraded to fit raw materials improvements to achieve optimum quality and throughput. Now, Sai offers Triple layer extrusion line in the following ranges: 30–50–38, 38–65–45 and 45–80–50.

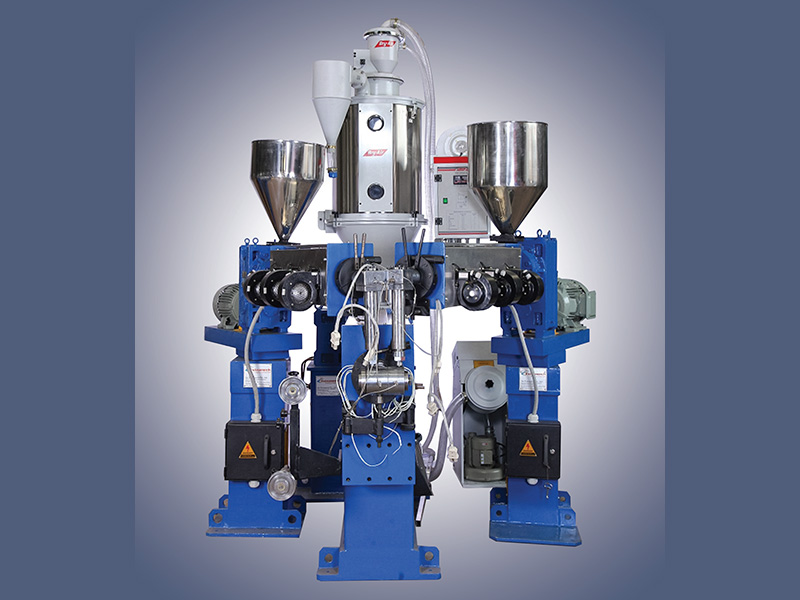

Sai supplies a highly advanced range of insulation line that is used for house wiring and control cables. The insulation line offers good flexibility and incorporates a dual extrusion system that helps in providing skin, single line and dual line through the piggy back mobile extruder. The piggy back extruder offers the advantage of space saving and could be easily changed for any line direction. With the base fixed to the ground, the extruder can be rotated 3600. Its head is self centered and helps in removing the problem of centering the cable; and thus minimum startup time is achieved.

Efficient workmanship and efficient designing ensure the minimum changeover time and help in giving the advantage of changing size and colour several times during production. It includes the multi pass cooling system that gives good cooling solution in the production process, primarily in high-speed lines. In this, cable gets the necessary time for proper cooling; the addition of dual take up system with two pay off in line facilitates the line to run consistently and helps in removing the stoppages during bobbin shifting resulting in high productivity. Moreover, it can be easily modified in compliance with client requirement and is delivered within the stipulated time frame.