Over the past few years, thermoplastic polypropylene-based power cable insulation systems have gained a lot attention in the global cable industry due to their excellent electrical behavior and production benefits. Polypropylene-based compounds, or PPC, are also called HPTE, high performance thermoplastic elastomer materials, in some contexts.

XLPE, silane and peroxide cross-linkable polyethylene insulation material, has already been dominating the power cable insulation material market for decades in land AC applications, and for roughly a decade in HVDC links. Now, polypropylene (PP) provides an equal or better alternative to XLPE. In polymer markets, polypropylene is the second-largest polymer after polyethylene (PE), with an annual usage growth rate of around 5-6%, and is therefore a raw material available globally.

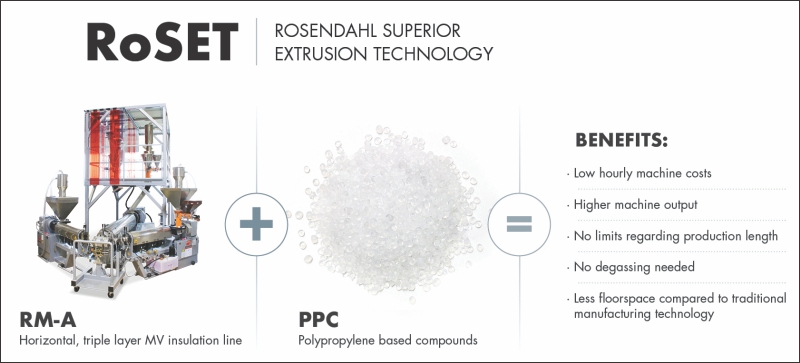

RoSET– Production Line, Material and Know-How for PPC MV Power Cable Production

Rosendahl’s R&D intensely investigated and tested PPC against in comparison with the well-established XLPE insulation material in medium voltage cables. A number of test cables were carried out using Rosendahl’s RM-A line in real manufacturing conditions. The results are outstandingly positive and verify the advantages of PPC in many aspects. It was evident to bundle the gained know-how and offer it to power cable manufacturers globally under the name RoSET.

RoSET, Rosendahl Superior Extrusion Technology, is a unique MV PPC cable-manufacturing concept for up to 30/36 kV power cables. It consists of a dedicated MV line-type RM-A, PPC MV insulation, semi-conductive materials and know-how package.

Full manufacturing concept from one source

In 2018 Rosendahl Nextrom GmbH and HV Cable Solutions Ltd. came together to develop an extrusion technology for PPCs, which was something new to the market. The cooperation combines MV cable know-how packages comprising PPC recipes, production process, cable performance guarantee and production equipment from one strong source.

Prior to the cooperation, over the past years, tens of full type tests and hundreds of additional individual tests, including short circuit tests, have been conducted for PPC solutions in the 15 kV, 20 kV and 30 kV voltage classes. The additional tests and 20kV and 30kV cable production run with Rosendahl’s RM-A line under real manufacturing conditions proved the PPC concept and resulted in an enhanced, high-performance RM-A production line optimized for PPC. An approved type test for RoSET 30/36 kV cable was performed by a European test institute.

RoSET PPC offers power-cable makers several benefits:

- The machine hour costs, including line operation, maintenance and employee costs, are significantly lower than for peroxide XLPE manufacturing

- The material costs of PPC insulation system compared to XLPE are typically lower

- The thermoplastic material allows for higher extruder speeds, and therefore higher line speeds can be used

- The PPC material allows for any length to be manufactured

- The production lead time is shorter, since degassing or the steam bath process is not necessary

- As the thermoplastic PPC material requires no curing, investment in degassing or steam bathing is not necessary

- The investment in the production line is lower due to the shorter line layout and horizontal line

- We guarantee that cables made with PPC meet the requirements

Based on the above, the RoSET concept, including an optimized horizontal triple-layer RM-A extrusion line, is the perfect solution for cable makers to enter a new market and boost their competitive position. The new RoSET insulation technology for medium-voltage cable manufacturing is now commercially available from Rosendahl Nextrom GmbH.