Rosendahl Nextrom, a global strategic partner for producers of cable and wire, introduces new equipment in datacom and the telecom sector. Rosendahl Nextrom’s presence will be found at the Wire India 2024 at booth I59.

Oct 21, 2024

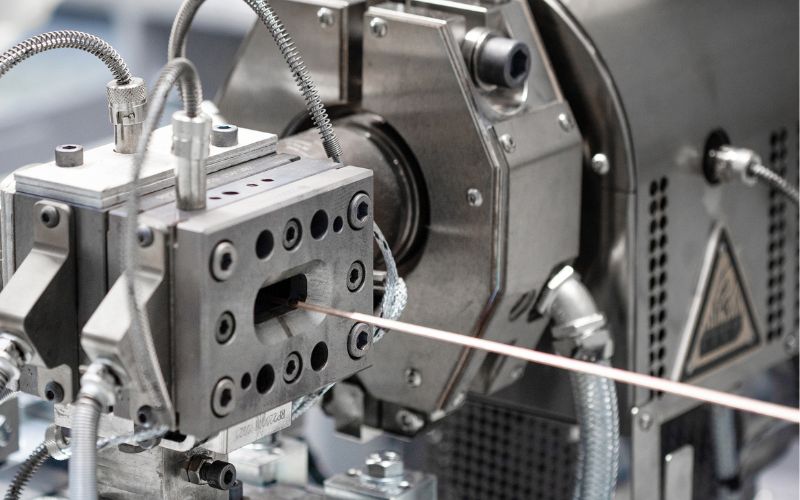

Rosendahl Nextrom has introduced high-temperature physical foaming lines that can manufacture cables with high bandwidth demands and help supercomputers think faster. Additionally, the company offers a new generation of datacom core insulation lines for CAT 7 and CAT 8 compliant cables with a skin-foam-skin construction.

The latest achievements in fibre optical cable manufacturing include a high-speed fibre launching system, a high-speed rewinding line and a proof testing & fibre colouring line with automated reel changes. These new solutions reduce operating time and scrap while increasing productivity, quality, and safety for operators.

The company is also revolutionizing preform manufacturing with a combination of Vapor Axial Deposition and Outside Vapor Deposition technologies tailored for producing large-sized preforms with the lowest operational expenses. Furthermore, the telecom fibre drawing process has been optimized to reach impressive speeds of up to 3,500 m/min.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

Rosendahl Nextrom also provides innovative solutions for the industry, including busbar insulation, high-end charging cables and high-performance data cables. With the world’s first turnkey extrusion line for hairpin insulation for safe and reliable power supply at 800V+, ,the much slower and less efficient enamelling process faces strong competition. The robust insulation with high-performance PEEK contributes to reduced charging times and increased ranges by minimizing energy losses in electric board systems. These solutions support the industry’s shift towards a more sustainable power supply. Their sustainable concept for forming, welding, and jacketing flexible materials and product sizes on a single production line is well-suited for connecting wind farms, photovoltaic farms, and offshore projects to the power grid.

In the medium-voltage segment, the use of recyclable polypropylene-based compounds eliminates the need for energy-intensive cross-linking. This new manufacturing concept creates a compact and sustainable alternative to conventional XLPE solutions without compromising on electrical properties.

A major focus of Rosendahl Nextrom’s efforts is the thoughtful use of materials, waste reduction, minimizing wear, and enhancing energy efficiency. Their powerful line control offers a wide variety of possibilities to continuously improve production in those areas. Recently, an AI-supported process control, ESG-compliant measurement of CO2 and energy consumption and a powerful tool for maintenance management have been added to the smart portfolio.

Also Read: Windak’s Innovative Coiling and Spooling Technologies

In the field of telecom fibre drawing, Nextrom is leading the way towards more sustainable production: A Helium Recovery System recovers up to 90% of the used helium, effectively reducing dependence on this limited resource. The return on investment for this system can be achieved within a year, considering the current prices and availability constraints of helium. Addition, the Nextrom Induction Furnace drastically cuts down on energy consumption.