May 8, 2013

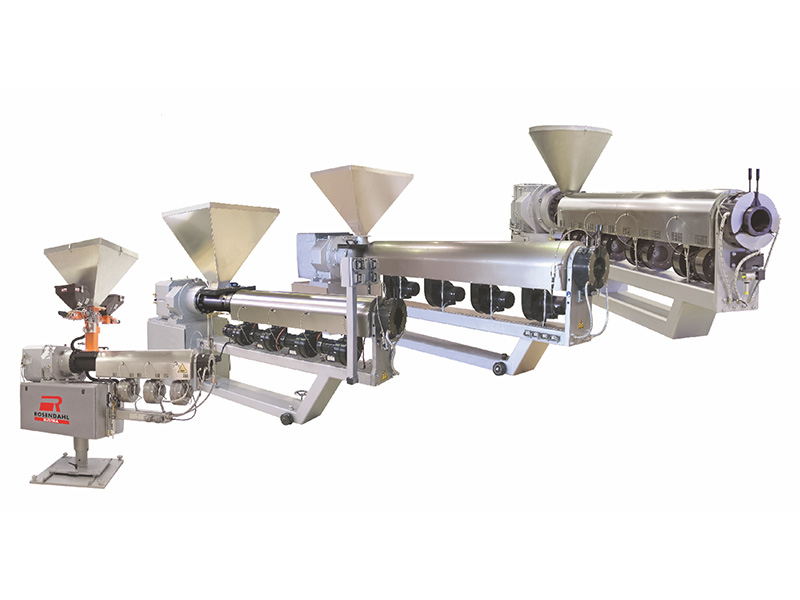

Rosendahl is the technology leader in the area of extrusion lines for years. One of the biggest milestones on the way towards this aim was the continuous improvement, which led to the ROEX Extruder generation.

To achieve a reduction of the power consumption Rosendahl was focused at the extruder unit (the main consumer of energy in an extrusion line) and developed measures to enhance the energy efficiency of the new Rosendahl Extruder Generation ROEX.

The following improvements were made:

• The drive has been modified from DC technology to state of the art A/C power technology. Additionally the thyristor rectifier, which caused enormous wastage due to reactive power was omitted.

• By converting to a direct screw drive by means of a planetary gear motor mechanical losses were reduced. The planetary gear is directly driven by four symmetrically aligned motors (“Compact Motor & Gearbox Design”).

• Thanks to an optimized processing unit (screw & feeding section) the material output could be massively increased. At the same time energy consumption decreased.

• During the development of the new Extruder Generation ROEX special attention was paid to additional electrical power consumers like the heating and cooling section. A new design of the heating elements in combination with the cooling channels and the fans allowed substantially faster reactions of the extruder temperature control.

The effect of this was not only a precise control but also a reduction of the power consumption of the heating and cooling section.

Needless to say, further machines of the Rosendahl extrusion lines were subjected to measures to increase efficiency.

It is of great importance to Rosendahl that the latest technologies are constantly applied (e.g. use of more efficient electronic components like AC motors, illuminants, conflation of several PLC systems, regulators and relays).

Furthermore Rosendahl uses a high-level line control system. This line control coordinates the processes of all machines and demands only the power, which is required for each particular process.

Rosendahl’s ROEX extruder generation saves compared to conventional production lines from 15 to 25% energy for the entire production line with a comparable productive capacity.