Prysmian offers a comprehensive range of solar cables designed specifically for photovoltaic (PV) systems. These cables are essential for the efficient and reliable operation of solar power installations, ensuring optimal performance and safety. Its focus on innovation and research allows the company to develop advanced solutions tailored to the specific requirements of the solar industry. The company established manufacturing facilities both in Chiplun and Pune, enabling us to cater to local demand with locally produced cables. “Our track record of supplying cables for major solar projects globally enhances our credibility in the Indian market,” Mr. Benoit Lecuyer, CEO, Prysmian India & ACPL maintains in an interview with Wire & Cable India.

Wire & Cable India: How much has the Indian solar wire and cable segment evolved over the years, and how are you positioned as a manufacturer in it?

Benoit Lecuyer: The Indian solar industry began to soar with government incentives and policies promoting renewable energy, with solar cables connecting solar panels to inverters and grid infrastructure. Initially, India relied on imported solar cables due to limited local manufacturing capabilities. With the increasing solar installations, the demand for high-quality, durable solar cables grew, and several domestic manufacturers entered the market reducing dependence on imports.

Prysmian and ACPL (Associated Cables) as a global leader in the cable industry, brings experience, and expertise in manufacturing high-quality cables. Our focus on innovation and research allows us to develop advanced solutions tailored to the specific requirements of the solar industry. We established manufacturing facilities both in Chiplun and Pune, enabling us to cater to local demand with locally produced cables. Our track record of supplying cables for major solar projects globally enhances our credibility in the Indian market, along with sustainable practices into their manufacturing processes, aligning with India’s increasing focus on sustainability in renewable energy projects.

WCI: How significant is the solar segment for you?

BL: The solar segment contributes a growing portion of the company’s revenue as global demand for renewable energy solutions rises.

The solar segment aligns with Prysmian’s strategic goals of sustainability and innovation. By providing cables and solutions for solar farms and installations, Prysmian supports the transition to renewable energy, which is a critical global objective. This strategic alignment helps Prysmian to position itself as a leader in the green energy market.

The global push towards reducing carbon emissions and increasing the share of renewable energy in the energy mix is driving significant investments in solar power. Prysmian benefits from these trends by supplying the necessary infrastructure for solar energy projects, including specialized cables and systems designed for solar applications.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

WCI: Please take us through your solar product portfolio.

BL: Prysmian offers a comprehensive range of solar cables designed specifically for photovoltaic (PV) systems. These cables are essential for the efficient and reliable operation of solar power installations, ensuring optimal performance and safety.

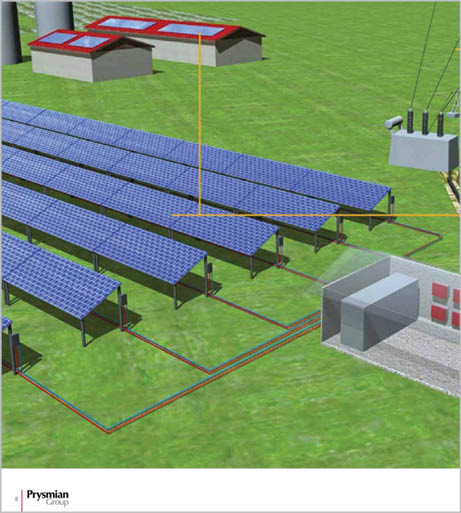

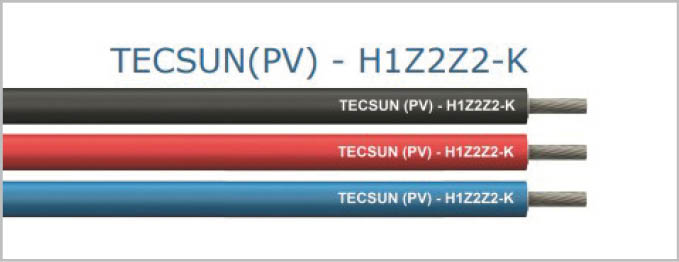

TECSUN – PRYSUN (PV) Cables: Single-core cables used in photovoltaic power systems for the interconnection of the various elements of a PV system, such as modules and inverters, designed to withstand harsh environmental conditions, including UV radiation and ozone. Three-core cables, providing the same benefits as the single-core variant, but are used for applications where three-phase AC connections are required. Both offer high durability and resistance to mechanical impacts, suitable for use in solar parks and other outdoor installations.

Low and Medium Voltage Cables: Designed for connecting PV systems to the grid. These cables are crucial for the reliable transmission of the generated solar power.

Fiber Optic Cables: For monitoring and controlling PV systems. These cables are used in smart grid applications and help in the efficient management of power generation and distribution.

Flexible Cables: Highly flexible cables suitable for both fixed and mobile applications in PV systems. Designed to be installed in various configurations and are resistant to environmental stress.

WCI: Based on end-users, such as residential, industrial and commercial, where do your solar cables experience more demand? Why?

BL: Commercial solar installations, such as office buildings, shopping centers, and warehouses, require significant amounts of cabling due to the larger scale of these projects compared to residential installations. Businesses are increasingly adopting solar energy to reduce operational costs and benefit from tax incentives, which drives the demand for reliable and high-performance solar cables.

Many companies have set sustainability targets and are investing in renewable energy solutions to meet these goals. This trend is particularly strong among corporations that need to demonstrate environmental responsibility to stakeholders.

Industrial facilities often have high energy demands and can significantly benefit from the cost savings provided by solar power. This leads to the installation of large solar power systems, increasing the demand for industrial-grade solar cables.

Industries seek to ensure energy security and mitigate risks associated with power outages. Solar power, combined with battery storage, offers a reliable alternative.

There is a growing trend of residential solar installations as homeowners look to reduce electricity bills and take advantage of government incentives and rebates for installing solar panels.

Homeowners are increasingly interested in achieving energy independence and resilience, especially in areas prone to power outages. Government incentives such as tax credits, rebates, and grants are major drivers in all three fields, encouraging investments in solar installations.

WCI: Where in the country do your products enjoy strong demand? Please elaborate why.

BL: Prysmian solar cables witness strong demand in several countries around the world, driven by a combination of governmental support, environmental goals, economic factors, and geographical advantages. Some important countries are the US, France, Germany, Spain, UAE, India, to name a few. State incentives and investment tax credits reduce the cost of solar installations. Many corporations are investing in solar energy to meet sustainability goals and reduce energy costs, driving demand for reliable solar products.

Strong commitment to reducing greenhouse gas emissions and reliance on fossil fuels makes Germany a key market for solar products. In India, the ambitious goal to achieve 100 GW of solar capacity, supported by the National Solar Mission, supports these goals. Solar power is critical for providing electricity to remote and rural areas, which are not well-served by the traditional grid. Also, favorable climatic conditions for solar power generation increase the efficiency and viability of solar projects.

WCI: What technologies have you incorporated into your manufacturing facilities to produce solar wire and cable? How unique are they?

BL: Prysmian uses state-of-the-art extrusion technology to manufacture solar cables with precise dimensions and high consistency. This technology ensures uniform insulation and jacket thickness, which is crucial for the reliability and durability of solar cables. Advanced extrusion processes allow the use of innovative materials that enhance cable performance, such as UV-resistant and flame-retardant compounds. The ability to work with specialized materials provides Prysmian cables with superior resistance to environmental stressors like UV radiation and temperature variations.

Prysmian employs smart monitoring systems that provide real-time data on the manufacturing process. This includes monitoring temperature, pressure, and other critical parameters. Energy-efficient technologies reduce operational costs and environmental impact, contributing to the overall sustainability of the manufacturing process.

WCI: Compared to other wire and cable, how different is the manufacturing process of solar wire and cables?

BL: Solar cables need materials that can withstand prolonged exposure to ultraviolet (UV) radiation without degrading, as well as endure a wide range of environmental conditions, including extreme temperatures, humidity, and exposure to ozone. They require materials that are flame retardant to enhance safety, and should undergo stringent testing for UV resistance, temperature cycling, mechanical impact, and longevity. They must comply with international standards like TÜV, UL, IEC, BIS.

Solar cables use insulation materials that are not only electrically insulating but also resistant to weather, UV radiation, and thermal stress. They are double insulated for added protection, ensuring better performance and safety.

WCI: How sustainable are your products? Please precise the process you have adopted to achieve it?

BL: Prysmian uses materials that have a lower environmental impact, such as lead-free compounds, halogen-free flame retardants, and recyclable materials. We are exploring and using bio-based plastics derived from renewable sources to reduce reliance on fossil fuels. Using eco-friendly and recyclable materials helps in reducing the toxicity of the cables and makes them safer for the environment and human health.

Some plants are powered by solar or wind energy. Using renewable energy and improving energy efficiency reduces greenhouse gas emissions associated with cable production. Reducing waste generation and promoting recycling helps in minimizing the environmental impact of their manufacturing operations.

Our cable products comply with regulations restricting the use of hazardous substances (RoHS) and chemicals (REACH). We use packaging materials that are recyclable and aim to reduce packaging waste.

Also Read: AVOCAB: Lighting the Way to a Self-Sufficient Renewable Future

WCI: Given India’s ambitious 500GW renewable energy target and solar wire and cable being the lifelines of the solar power system, what kind of growth prospects are you staring at?

BL: Given the critical role of solar wire and cable in the solar power system, Prysmian can anticipate several key growth opportunities.

The large-scale solar projects required to meet this target will drive significant demand for high-quality, durable solar cables. Expanding solar power to rural and remote areas will also require extensive cabling infrastructure, creating additional demand. With many large-scale solar farms being planned and constructed, Prysmian will capitalize on supplying cables for these extensive installations.

The commercial and industrial sectors are increasingly adopting solar power to reduce energy costs and meet sustainability goals, further expanding the market for Prysmian’s products. The residential solar market is also growing, albeit at a smaller scale compared to utility and commercial and industrial sectors, contributing to overall demand.

Developing and supplying advanced cables that offer superior performance, such as better thermal resistance, UV protection, and longevity, will position Prysmian as a preferred supplier. Innovation in smart cables that enable monitoring and efficient energy management can create a competitive advantage.

Collaborating with government bodies on solar projects can provide steady and large-volume contracts, as well as forming alliances with major solar panel manufacturers and project developers to secure our place as a key supplier. Strengthening brand recognition through marketing and participation in industry events solidify our Prysmian and ACPL presence in the Indian market.

Finally, the integration of large-scale solar power into the national grid will require robust cabling infrastructure, offering opportunities for Prysmian and ACPL.

WCI: Discuss some of the major challenges you have been experiencing as a manufacturer in the industry? What could help overcome them?

BL: Navigating the complex processes for approvals and permits can sometimes delay projects. Fortunately the changes in government policies related to tariffs, subsidies, and import duties are rare now, and rather stable.