The new 245 kV HVAC dynamic cable system will ensure that offshore wind projects benefit from superior resistance, high mechanical performances and boosted reliability to overcome the extremely challenging conditions at sea caused by the constant stress due to water currents and harsh conditions at sea.

Mar 6, 2025

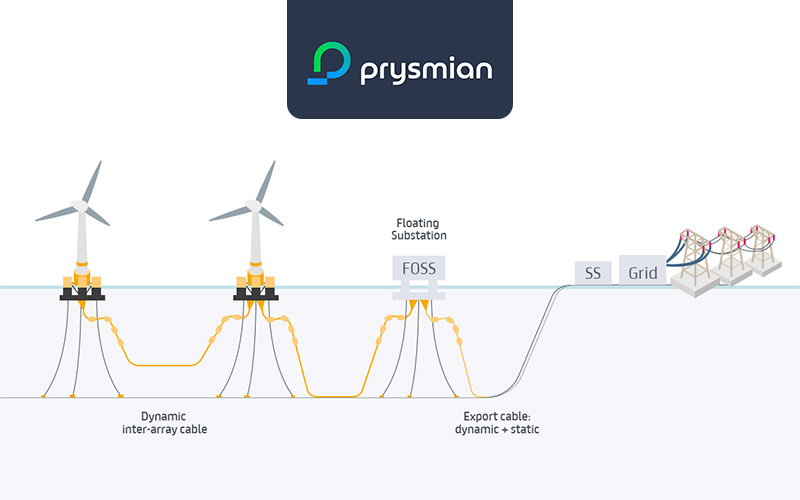

Prysmian has made a significant breakthrough to accelerate the roll-out of floating offshore wind projects. Floating offshore wind, a technology which opens wind-power generation to previously unreachable areas due to the deep seabed, will be significantly boosted by this breakthrough, as Prysmian can provide high voltage dynamic cable systems that have been tailor-made for such conditions.

Watch: Top Cable Companies in India

The new 245 kV HVAC dynamic cable system will ensure that offshore wind projects will benefit from superior resistance, high mechanical performances and above all, boosted reliability to overcome the extremely challenging conditions at sea caused by the constant stress due to water currents and harsh conditions at sea. Prysmian is the first player in the market to have such a full portfolio of dynamic cable systems from 72.5 kV inter-array to 245 kV export tail cables.

The 245 kV HVAC dynamic cable was manufactured at Prysmian’s centres of excellence in Pikkala (Finland) and Arco Felice (Italy) and will be the enabler of floating offshore market opportunities in both Mediterranean and Northern seas. This achievement was part of Prysmian’s innovation roadmap and follows the successful completion of Gruissan and Provence Grand Large pilot floating offshore wind farms in France, underlining Prysmian’s global leadership in accelerating the delivery of Europe’s energy security and transition.

Also Read: REC Limited Signs MoU with MP Government for Power Infrastructure Development

Electrical and mechanical qualifications were conducted following international standards, including CIGRE TB490 & CIGRE TB862 and were witnessed by a third-party certification body. The qualification program also included flex fatigue tests to prove the cable’s life-long durability and performance for floating offshore wind applications.