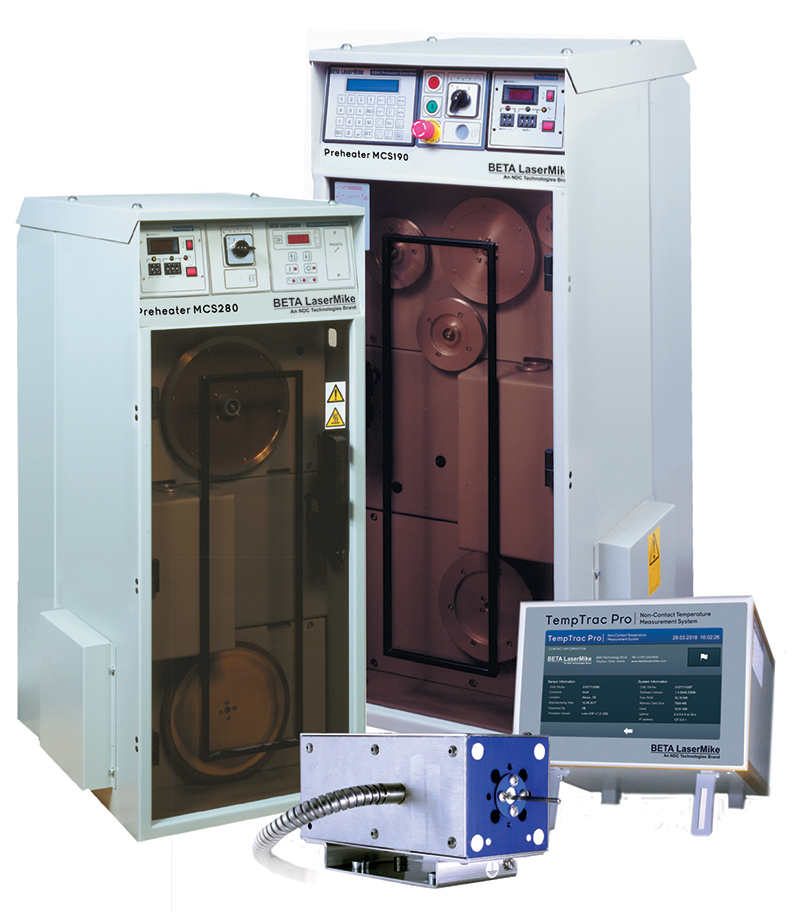

BETA LaserMike Preheaters can be equipped with the new TempTrac Pro non-contact temperature measurement system for high-accuracy monitoring and control of preheat temperatures.

February 13, 2019

BETA LaserMike Preheaters from NDC Technologies provide uniform, in-process wire heating to eliminate insulation voids in primary cables. When a wire is preheated for only fractions of a second by a low frequency (50/60 Hz) heat cycle, the heat is unevenly applied to the wire, resulting in hot and cold spots.

BETA LaserMike Pre-heaters solve this problem by using high-frequency preheating that applies the optimum heat cycles to the wire as it passes through the Pre-heater. This ensures a linear and consistent heating along the length of the wire, regardless of speed, to meet the unique temperature requirements.

The TempTrac Pro Sensor enables in measuring the preheat temperature of the wire and cable with the highest accuracy. It can measure wire diameters from 0.28 to 2.80 mm. The TempTrac Pro Controller closes the loop to improve process efficiency and product quality while minimizing waste. It can be provided as a stand-alone system or can be integrated with the BETA LaserMike Preheater system.

The BETA LaserMike line of measurement and control products are designed to increase productivity, improve product quality and reduce manufacturing costs. Every system is backed by NDC’s world-class service and support organization. With offices around the globe, NDC is committed to serving the unique measurement application needs of customers.