The role of Diamond dies is very important in the efficient operation of a drawing plant. While the Indian wire and cable industry is growing rapidly with new investments pouring in every day, an attempt must be focused at enhancing the efficiency of the drawing plant, in which proper die usage and its maintenance plays a pivotal part. The significance of the above theme was outlined by Mr. B. Kamal Babu, Managing Director of Mikrotek Machines Ltd. in a technical seminar during the Cable & Wire Fair 2017 at New Delhi.

When we talk about the drawing plant efficiency, it is imperative to know what a drawing plant wants. A continuous good wire drawn on a long-term basis with least number of wire breaks per tonne drawn is something which every wire drawing plant aspires. In addition, lowest die cost per ton of wire drawn is also desired.

When we talk about the drawing plant efficiency, it is imperative to know what a drawing plant wants. A continuous good wire drawn on a long-term basis with least number of wire breaks per tonne drawn is something which every wire drawing plant aspires. In addition, lowest die cost per ton of wire drawn is also desired.

What is a Good Wire?

A good wire is characterized as having correct size, good roundness and ovality, required surface finish, and all the required metallurgical properties. In addition, minimum guaranteed length without joints is also a very important parameter of a good wire, especially when it comes to the industries where robots are deployed on large scale, like in the automobile industry. Cast effect is also a significant factor in a good wire apart from other properties which a cable customer wants.

Present Situation in India

Mikrotek’s customers are spread across the world. The company has canvassed the drawing practices of different customers to reach at some starkly observable differences. The comparative study of drawing plants shows that there is big room for improvement in terms of drawing speed and number of wire breaks. In India, most of the drawing machines are running around 60% of the designated speed. For example, if a multi wire drawing machine rated speed is 30.5 mtrs per second, in reality due to various reasons the drawing machine is run around 18 mtrs per second. This is not the best-case scenario and the industry must put efforts in realizing the top designed speed. When the wire and cable industry everyday is adding capacities, it is rather more important to prioritize to improve the efficiency of the existing machines.

Moreover, the incidence of more number of wire breaks is another menace. The norm in India is 0.5-1 wire breaks per tonne, which is significantly higher than the efficient drawing plant average of 1 break per 20 ton. We are lagging so much behind.

CR value is one of the most important parameters required in the cable manufacturing. In order to achieve the CR value, machine operators tend to adjust the dancer pressure of the drawing machine and in the process give away more metal, a highly wasteful affair. Another problem is the generation of metal dust while drawing wire and this dust gets circulated affecting the wire’s surface and dimensions. These factors together and or individually put a serious question mark on the efficiency of the drawing machines. How to overcome this?

How to Increase the Efficiency and Retain It?

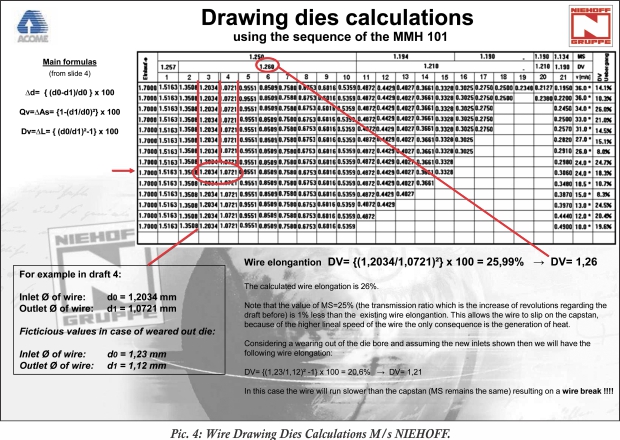

The five important factors that have to be taken care to achieve highest productivity on drawing machines, especially on Multi wire drawing machines are inlet rod or wire quality, good lubricant, efficient filtration and lubricant temperature, drawing dies sequence with customized die profile, periodical die maintenance and drawing machine maintenance. The wire manufacturer must first ensure the right selection of dies with the help of ‘drawing dies specifications’.

It is most important to maintain the dies periodically to ensure that right quality dies are used at all times.

Wearing of Dies and Repercussions

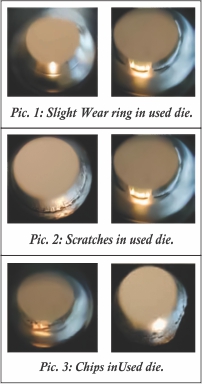

Due to continuous drawing, a wear ring forms at the contact point inside the reduction angle. Also, due to fine metal dust, very fine scratches develop from contact point to the edge of the bearing. In some cases, due to different drawing conditions, the wear and tear will be severe and deep scratches and chips will occur in the drawing die. Due to this, the diameter, roundness and wire surface quality will change. Also, the wire breaks will start and drawing machine’s behavior will be erratic. This will increase the machine downtime. As a consequence, the machine operator will struggle and find a solution by adjusting to lower speeds, thereby severely compromising with the efficiency of the drawing machine. With time, the die profile changes and if we want to maintain the drawing machine speed and quality of the wire, the solution is to re-polish the dies periodically i.e. polishing ensures removal ofthe wear ring and any fine scratches in the drawing zone and the die will become like near brand new. Also, the round becomes very good. Picture 1, 2 and 3 depicts the wear patterns in used dies.

Due to continuous drawing, a wear ring forms at the contact point inside the reduction angle. Also, due to fine metal dust, very fine scratches develop from contact point to the edge of the bearing. In some cases, due to different drawing conditions, the wear and tear will be severe and deep scratches and chips will occur in the drawing die. Due to this, the diameter, roundness and wire surface quality will change. Also, the wire breaks will start and drawing machine’s behavior will be erratic. This will increase the machine downtime. As a consequence, the machine operator will struggle and find a solution by adjusting to lower speeds, thereby severely compromising with the efficiency of the drawing machine. With time, the die profile changes and if we want to maintain the drawing machine speed and quality of the wire, the solution is to re-polish the dies periodically i.e. polishing ensures removal ofthe wear ring and any fine scratches in the drawing zone and the die will become like near brand new. Also, the round becomes very good. Picture 1, 2 and 3 depicts the wear patterns in used dies.

Periodic Die Maintenance

Die maintenance of used dies involves microscopic inspection to check the wear pattern inside the die profile caused by wire drawing and to decide whether the die has to be re-polished or resized.

Re-polishing is done for the dies with slight wear (Light wear ring, fine scratches on die surface etc.) but the die size is within the tolerance, and the bearing length is free from any damages. After re polishing, the dies can be used for the same size. Resizing is done for the dies with severe wear. (Deep wear ring, deep scratches and chips within the profile) and the die size is out of tolerance. Resizing involves similar work like making a new die. The die may be finished to the next nearest size.

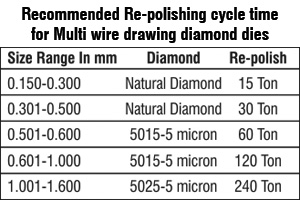

Re-polishing cycle time depends on type of material drawn, speed of drawing and type of dies used. One has to regularly monitor the wear pattern in the dies (to be decided by the in house die expert) by inspecting the dies under a microscope and deciding whether to re-polish or resize. Usually, final dies need frequent re-polishing for continuous production of good wire.

Equipment required for re-polishing and reconditioning of used dies are usually Semi ultrasonic die grinding machine for shaping of die profile, wire polishing machine for sizing of the dies, ultrasonic polishing machine for polishing of die profile, ultrasonic cleaner for cleaning the die inner profile and microscope for visual inspection of die profile etc.

Equipment required for re-polishing and reconditioning of used dies are usually Semi ultrasonic die grinding machine for shaping of die profile, wire polishing machine for sizing of the dies, ultrasonic polishing machine for polishing of die profile, ultrasonic cleaner for cleaning the die inner profile and microscope for visual inspection of die profile etc.

How to Maintain Dies?

A perfect die maintenance process starts with sourcing the good die set. Means, dies are strictly manufactured and supplied as per the ordered specifications along with a test certificate. The die maintenance is a skilled work and requires a set of equipment and a dedicated operator.

A perfect die maintenance process starts with sourcing the good die set. Means, dies are strictly manufactured and supplied as per the ordered specifications along with a test certificate. The die maintenance is a skilled work and requires a set of equipment and a dedicated operator.

Every wire company should decide the re-polishing cycle based on the copper quality and drawing machine. Normally, for a size of 0.200 mm, the re-polishing cycle is approximately 15 tonnes in case of copper wire and 100-120 kgs in case of stainless steel wire. The drawing company should have either in house die maintenance room or tie-up with a good die company for regular re-polishing of their die sets. This simple exercise on regular basis will ensure highest efficiency of the drawing plant. A typical re-polishing cycle is enclosed for reference.

Which is a Good Die Company?

A good die company is usually the one which is reliable, trustworthy and preferably experienced. The company must have sound technical knowledge and ready to share information on die selection, usage and its proper maintenance. Moreover, a good die company always supplies as per the customer requirement and advises the customer on specifications and correct blank or diamond used. Also, ready to discuss and share latest developments and improvements. The company producing dies should be willing to train the customer on die maintenance. After sales service is also one essential feature of agood die company, which in case of any problem immediately extends route cause finding and CAPA (Corrective Action & Preventive Action).