Within the Smart Monitoring family of Maillefer, the users will be able to access real-time monitoring of the performance of entire production lines or certain machines in a line.

March 01, 2021

Data gathering and data monitoring is a clear trend in the process industry. It is the way to truly know what is happening in the line in real-time as well as having all the background data stored for future use. Smart Monitoring gives you many benefits and a leading-edge with your end customers.

The Concept

Maillefer is offering a unique opportunity with this new smart product, where customers begin real-time monitoring of the performance of entire production lines or certain machines within a line. This monitoring can be the key process parameters from one line or from several lines producing the same quality, even lines from different suppliers. There is also clearly a market need to monitor certain quality-related parameters. In this case, various measurement gauges are connected for real-time data collection, storage, and analysis to secure end quality.

Manufacturing Floor Data

Within the Smart Monitoring family, Manufacturing Floor Data is the first of the two different product offerings. This product stores relevant data tags (i.e. data fields) from production for an unlimited time. You can assign tags to a Maillefer line, another supplier’s line, or any machine or smart sensor. The goal is to make data available to analyze whenever needed. The storage is basically unlimited yet determined by disk capacity and a wise backup strategy. The analysis tool is the familiar Historian Client, where tools for Trending, Reporting, and Direct Query of the data are included. You may choose to collect either the standard 500 tags or opt for a bigger package of 5000 tags. The standard is well suited for cases where you need to gather certain quality-related parameters from all lines and you have similar measurement gauges (e.g. diameter gauges). When you are dealing with bigger, more complex lines having multiple parameters (e.g. a full energy cable production line), selecting 5000 tags would be a wiser choice.

Manufacturing Floor Excellence

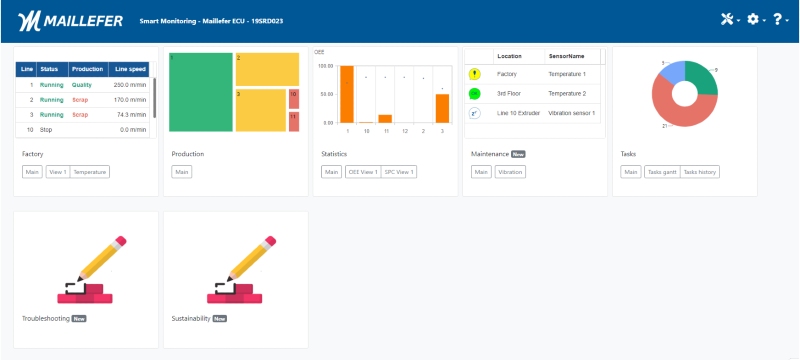

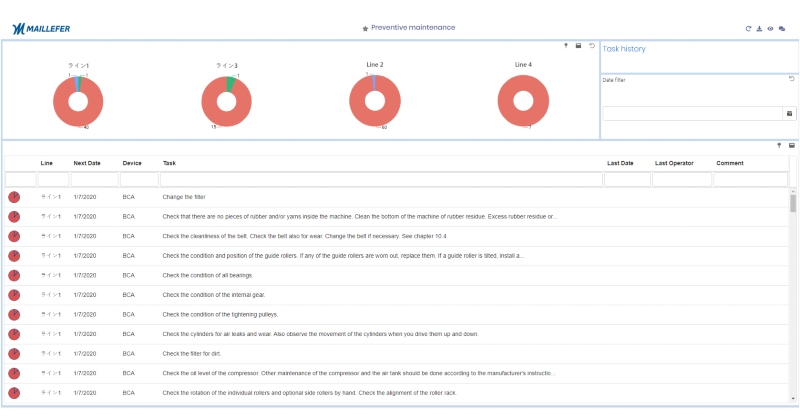

This second package offers powerful analysis and accelerated decision-making features. The highly visual, informative, and custom-tailored dashboards bring a wider understanding into the manufacturing process. Its introductory configurations offer easy solutions for management and production personnel. It also includes machinery maintenance functions through Preventive Maintenance. Indeed, a PM module integrates the maintenance tasks schedule, descriptions, and engineering documents. Personnel gets direct access to the right information to oversee and realize maintenance jobs.

With Manufacturing Floor Excellence your maintenance team is kept up-to-date about the tasks in the production line for all components. They are able to easily plan their activities weeks ahead for the next production shutdown. You are provided with access rights for modifying and adding tasks that you know are vital for certain machines and where you need to guarantee long-term operation.

Future Offerings

Maillefer is constantly increasing the amount of intelligence available for its production lines. With Smart Monitoring, user understanding increases. It becomes faster and easier to make the right decisions about changes in operations and processing. Smart Monitoring offers the tools to maximize line output while minimizing scrap and material usage. The system goes beyond usual line sensors to include vital readings coming from other sources like vibration, temperature, and power consumption gauges, plus more. All this relative information feeds into Smart Monitoring seamlessly, thus allowing this tool to extend and evolve with you and in the years to come. Join Maillefer as we step into a new era of monitoring to help you reveal the true potential of your production equipment

By – Mr. Roger Möller, VP Maillefer Services, Maillefer Extrusion Oy