Rosendahl Nextrom loose tube line can process PBT microtubes with the speed of 1,200 m/min, meeting all the requirements with precision.

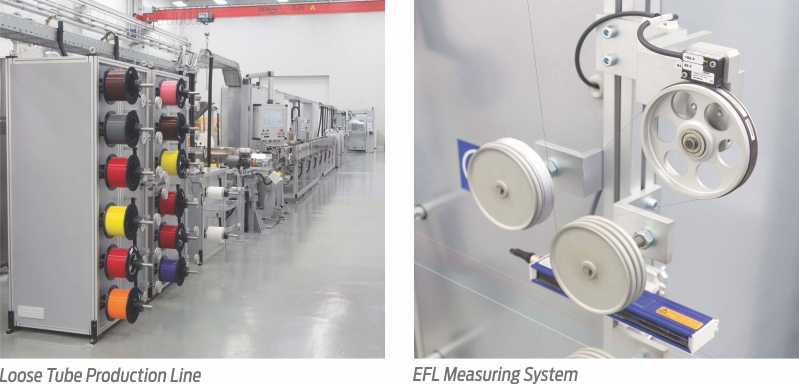

Precise, fast, and suitable for a wide product range – these are the crucial requirements for a loose tube manufacturing line. Rosendahl Nextrom has combined its customers’ needs with their own expectations and invented a totally new line design.

Perfect processing up to 1,200 m/min

The loose tube market trend for small-sized products is ongoing. On the latest Rosendahl Nextrom loose tube line, PBT micro tubes can be processed at line speeds of up to 1,200 m/min, meeting all product requirements with precision.

Watch: RR Kabel: Shreegopal Kabra on Fire Safety

Space saving line setup

With a line length of around 30 meters, the small footprint of the loose tube line is outstanding. It is made possible by a short cooling trough design and a new linear guiding. That saves space coupled with utmost performance.

Online EFL monitoring

A great benefit is the option to monitor excess fiber length (EFL) online. That enables you to get fast feedback during production and to react immediately during the process. An offline EFL measuring system is also available.

Improved line components

The Rosendahl Nextrom crosshead with linear guiding has been further optimized and works for dry as well as jelly-filled applications. An improved clenching capstan helps to minimize the excess length of the fibre and post-shrinkage of the PP/PBT tube during the production process. It is one of those crucial parts in the line that help you produce a storable, temperature-insensitive product at a high yield. In addition, Rosendahl Nextrom has equipped the line with a fibre cutter, a rewinding mode, and dual take-up for automatic reel changes. All these improvements contribute to a highly efficient production process.

Also Read: Rosendahl Nextrom: Focusing on Technology for Mobility, Digitalisation and Energy Transition

Demonstration line in Austria

One can experience a Rosendahl Nextrom loose tube line in real-life by simply visiting the company in Pischelsdorf, Austria. At their Technology Center, one can observe the line during production and interested parties can bring their individual materials and recipes for tests on the laboratory line.