Indian power transmission and distribution sector is looking forward to a period of capacity expansion and enhancing presence from urban to the most remote areas. There is enough scope for an existing and new organization to grow and make profits, however, to unlock these attributes, strategy, and innovation would be required. Laser Power and Infra have these already in place, owing to its market experience, and the vision of its leaders, Mr. Devesh Goel & Mr. Akshat Goel, Directors of Laser Power & Infra Private Limited (LPIPL). The company is a well-known name in the country, especially in the Eastern region, undertaking EPC projects as well as supplying products for their application. Its R&D team is working to consolidate all the internal data on its own interface. This conscious coupling of information technology will surely help the company achieve its 100 percent capacity expansion target.

“As of now, we have more than INR 5,000 crore invested in EPC projects, and our cables order book accounts for INR 1,000 crore. We have also recently acquired UIC Udyog Limited, which is a galvanized steel manufacturing company”

Wire & Cable India: Please share with us Laser Power’s journey and crucial milestones achieved along the way.

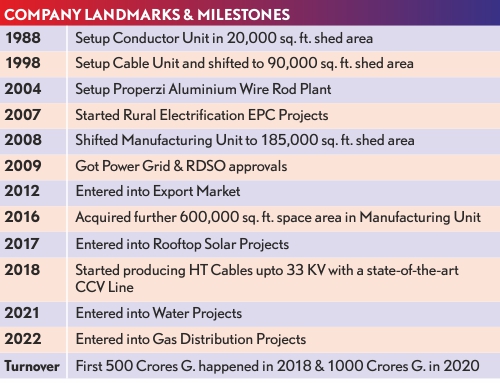

Mr. Devesh Goel (DG): Great things have small beginnings. The journey of LPIPL started from a small shop in Ezra Street, with an electrical cables trading business. My grandfather made a modest beginning, but we were very focused and seized every opportunity that came our way. My father, Shri Deepak Goel, joined the business in the late 80s and with his vision, approach, and hard work, the company grew exponentially. With his vision, the company has done both backwards and forward integration through acquisitions and mergers. His vision is to make Laser Power as one of the leading power infrastructure company in the world through technological upgrading, 100 percent automation, and by expanding new geography and foray into new markets.

Liberalization of the economy in the early 90’s, along with power sector reforms gave us the platform to expand our business & explore new territories. The company made a major foray in expanding manufacturing capacities & started its EPC business division.

Over the years, the power sector has grown exponentially both in capacity addition in power generation & in transmission & distribution sector. Power sector reforms continue to be the main focus area. With the growth of the power sector, the company also continued to grow, being one of the key players in the power sector.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

WCI: Please tell us about your manufacturing setup, product portfolio, and EPC division’s projects.

DG: We have three manufacturing plants, all in West Bengal, at Dhulargarh, Howrah, Kharagpur, and Kalyani. All of them are involved in the manufacturing of different products. In Dhulargarh and Kharagpur, we are engaged in manufacturing of conductors upto 765 KV and power and control cables upto 33 KV. Our product range comprises ACSR, AAC, and AAAC conductors, MV overhead covered conductors, and AL-59 conductors, PVC insulated power and control cables, MV and LV aerial bunched cables, LV PVC control cables, LV PVC power cables, LV XLPE control cables, LV XLPE power cables, MV power cables, underground jelly filled quad cables, railway power cables, and railway signaling cables.

We also manufacture aluminum rods and aluminum alloy rods in our properzi unit. We are also manufacturing PVC compounds in-house, required for our cable units.

In Kalyani, we manufacturer entire range of steel wires comprising HT steel indented & plain wire, used for PSC pole industries; ACSR core wire & strand – size 1.57mm to 4.77mm and cable armouring wire; GS earth wire; G.I. stay wire, G.I. wires of all sizes & grades; barbed wires and earthing coil; M.S. & G.I wires of all sizes.

Our EPC Division started in 2007 and has really done very well in terms of volumes and timely executions of projects. The company has completed many prestigious projects for central utilities like NTPC, Power Grid, BHEL, NHPC, ONGC & DVC etc. to name a few. The company has also executed many projects for various state government utilities in West Bengal, Bihar, Odisha, Assam, and Jharkhand. Repeated jobs from these utilities are a testimony of the quality of performance of the company,

The company has already electrified around 13k villages, and has given more than 15 lakhs house-hold connections. The company has erected and commissioned more than 60k ckm of HT & LT overhead lines, 109 ckm of HT 33/11 KV underground cabling, and more than 150 33/11 KV sub-stations (new/augmentation).

WCI: Could you elaborate on your market footprint and clientele?

DG: We have a very strong domestic market presence, looking into a vast clientele base. We are amongst one of the major players in the country in our field. We are serving both government utilities (center and state) and private sector companies. Our clientele includes Indian Railways, Powergrid, NTPC, BHEL, NHPC, ONGC MRPL, WBSEDCL, APDCL, DHBVN, Madhya Pradesh Power Transmission Company Limited, SAIL, etc., and our private sector clients include L&T, Tata Steel, Godrej, Jindal Steel & Power, Tata Power, Adani, Sterling & Wilson, Bajaj Electricals Limited, KEC, JSW, Shapoorji Pallonji, Aditya Birla Group, and Kalpataru Power Transmission Limited among many others.

We are also very active in international markets and regularly supply to various power utilities in South Africa, Africa, Nepal, Bhutan, Maurois, Dubai, Sri Lanka, Bangladesh, etc.

WCI: How does Laser Power use R&D to fuel its growth?

Mr. Akshat Goel (AG): R&D is the integral part of any successful enterprise. We have also invested very heavily on R&D not only to upgrade the existing products and manufacturing facilities but also by introducing new products and manufacturing processes in our system. This is very essential to cater to the ever growing demand of the customers. Today our product line is fully integrated through scada systems.

Further, data and information are the lifelines of the 21st century and we are trying to integrate technological advancement into our company. Our vision is that all our products, services, customers, vendors, and any possible determinant could be integrated within a single interface. This will allow Laser Power to access our internal information and data within seconds, and cut down our servicing and lead time by a significant margin. Presently we are using an integrated interface to sign contracts, issue orders, internal processes, etc., but our R&D team is still working on improving it to next-level technology.

WCI: Do you believe exhibitions contribute towards the growth and development of any industry?

AG: Yes, I do believe that exhibitions drive the industry to make a community effort toward growth and development. Our targets are not ordinary and to achieve them we need not only participation but a substantial contribution from every unit of industry. We take support of exhibitions to drive a community effort as they are huge drivers of international and domestic business, the domino effect of which continues over the years. It is hence a great opportunity for us to attend industrial exhibitions and fairs. In fact, we will be participating in Cable & Wire Fair, a global B2B exhibition for the wires and cables industry, in October and look forward to unlocking immense business opportunities there as well.

WCI: How do green energy and sustainable growth fit into the Indian scenario?

AG: India’s power sector is undergoing significant transformation, with the country working to increase generation capacity, expand the transmission and distribution network, and improve access to electricity. The government has set ambitious targets for increasing the share of renewable in the energy mix, and there are several initiatives underway to promote the adoption of clean energy technologies.

Green energy is the next big thing and sustainable growth is the need of the hour, especially for India. India is growing on various levels, and as urbanization reaches our most remote areas, an immediate inference is a reflection of urban culture in all parts of the country. Today when we enter any enclosed space we can spot and name at least 10 electrical or power-consuming appliances. With growth, this scale of consumption will also increase, and we need to ensure that the development we are driving doesn’t deny our future generations a chance to enjoy the same. This means that while we expand our power generation we need to shift in favor of renewable energy sources or green energy.

Subsequently, our power distribution sector also needs to grow and be more organized so that we do not exploit our resources towards waste and the same level of luxury and comfort can be ensured for our future generations. The Indian government is taking various steps to cut down the losses of public distribution companies as people opt for trickery and theft to access power sources like LPG and electricity. These fallacies are in fact a by-product of substandard manufacturing practices and need to be curtailed in favor of qualitative and price-competitive growth.

The transition to green energy is India’s chance to improve the situation and deservingly earn its title of being a superpower and hub of innovation and growth.

Also Read: Thermo Cables: Pioneering Speciality Cables, Competing with Global Leaders

WCI: CSR is one of the great initiatives to contribute to society in return for its resources. Can you elaborate on how Laser Power uses this opportunity?

DG: We undertake activities that are in accordance with our CSR responsibilities and also with our culture and ethos. Our CSR activities stem from our legal responsibilities and familial roots, for instance, we have a dairy farm in which we take care of about 1200 cows who have got injured, been abandoned due to old age, are malnourished, or are suffering from any disability.

We have made donations for ventilators installation, which were a huge necessity during the pandemic, in hospitals and deployed various health, like masks and sanitizers, and basic necessity resources, such as food, and temporary tents for migrators and the unprivileged, to tackle the unprecedented health and humanitarian crisis arising from the COVID-19 pandemic outbreak. We have also contributed to various awareness training projects on health and education in rural areas of Bihar and West Bengal headed by the central or state governments. We provide for all educational and living needs, including books, stationery, fees, food, clothing, etc., for a class of students at a West Bengal school for underprivileged students.

WCI: What are your plans for Laser Power’s future?

AG: Indian economy is in the process of growth and development, and this phase is going to last at least 10-20 years. The government already has Vision 2047 in place and various schemes and projects have already been launched to drive ground-level action. The infrastructural growth is being focused primarily and huge capex investments have been announced for the same. In such a scenario every Indian organization is looking forward to investing and generating exponential growth and profits.

At Laser Power as well, we are aiming for a 100 percent capacity expansion. Power consumption is increasing and we need better practices and systems in place, as I mentioned earlier, so we are looking forward to using our market presence for these purposes.

Urbanization and infrastructural growth have other collateral applications as well, such as water supply, fuel applications, etc, and we are looking forward to tapping new markets. We are venturing into water distribution and LPG gas distribution sectors as well. We recently acquired G M Dalui Valve Private Limited, a valve manufacturing company, and have bagged INR 300 crore water distribution project in Kuchinda, Orissa. We also have undertaken an LPG gas distribution project in West Bengal.