Mr. Gary Bateman, Managing Director, LAPP India Pvt. Ltd., talks about the recent innovations & upgrades at the company, the steps undertaken to foster innovations and the technology-driven products.

“Our teams are actively working on integrating Industry 4.0 concepts such as smart supply chains into our operations and developing high-speed connectivity solutions. We are also targeting to pilot smart factories in different locations of LAPP.”

Wire & Cable India: Please highlight technology and quality development or up-gradation that recently took place.

Gary Bateman: As part of the initiatives to incorporate cutting-edge technologies into our various processes and functions, we have recently installed and commissioned a state-of-the-art tandem extruder with customised screw and barrel configurations to extrude compounds for speciality cable applications. Another addition to our facilities is a state-of-the-art compounding plant with speciality extruders for manufacturing PVC and other proprietary compound formulations. We have also been investing in the latest technology related to the development and testing of such proprietary compounds. Additionally, we are installing a 3 MeV electron beam accelerator to manufacture cables for renewable energy, building & infrastructure businesses.

We have recently obtained IS 17048 certifications for our HFFR single-core and multi-core cables. We have also obtained 66 for safety fixture wire, UL 83 for thermoplastic-insulated wire and cables, UL 1277 and UL 2277 certification for tray cables and ISO/IEC 17025 accreditation for our laboratory in LAPP’s manufacturing facility situated in Jigani, Bengaluru. The ISO/IEC 17025 certification provides the assurance that the laboratory is delivering good services and consistent data.

Watch: Wire & Cable Industry Year Review

WCI: What have you been doing to foster innovation and R&D at your workplace?

GB: LAPP’s focus is centred on innovation. It is our guiding principle, and we are constantly working towards identifying evolving industry challenges and meeting customer requirements. Along with constant engagement with our customers, we are also increasing our presence geographically to be closer to our customers. We encourage our teams to think creatively and collaborate to develop innovative products and solutions. We have established a dedicated R&D team in India to develop products to meet the local market requirements. We also recently inaugurated our third Center of Excellence (CoE) at the Maulana Azad National Institute of Technology (MANIT) in Bhopal, with the aim of partnering with young minds to innovate.

Our innovations and developments are not just limited to our products. Our new corporate office at IBC Knowledge Park, Bannerghatta Road, Bengaluru is a uniquely designed modern workspace that incorporates the hybrid model of working. The office space is designed to fuel creativity and enable increased communication between departments, which we believe is the key to encouraging innovation and growth.

WCI: What is your technology and business roadmap for the coming times?

GB: We target to become an INR 1700 crore company by 2027. Our strategy for the company is developed on two major pillars – business growth and understanding customer requirements. We will be focusing our efforts on certain customer groups and exploring the avenue of opportunities offered by joint ventures. We aim to continue setting industry benchmarks with our leading innovations and dedication to quality and unparalleled service. Finally, we will continue to drive a family-oriented culture of mutual support and trust.

India is currently LAPP’s second-largest market, performing with double-digit growth and strengthening across various industries and applications. We are focusing on expanding our reach through various touchpoints across India and scaling up our local manufacturing capacity to meet the growing business demands. While we already have a strong presence in textiles, machine tools, automotive, railway, infrastructure and mining sectors, we are looking at adding more segments to our portfolios, such as EVs and pharmaceuticals.

ÖLFLEX® CONNECT and industrial communication will continue to remain major business priorities in LAPP’s journey as a one-stop solutions provider for all cable systems requirements. We are heavily investing in R&D for our Indian customers, and we will focus our efforts on manufacturing products locally- to continue providing products of global quality standards. In our endeavour to be closer to our customers, we will be tripling the number of LAPP’s service points in India in the next few years as well as be available online 24×7 for our customers.

WCI: Kindly elaborate on some of the industry 4.0 initiatives taken by your company.

GB: A preventive approach is always key in ensuring maximum productivity and efficiency. Building on this, LAPP has launched Health Check Service as part of the expansion of its service business – one of the first to be actively promoted for customers to use. With Industry 4.0 and digitalisation increasing the load on machine networks, the network technology should be as functionally reliable and powerful as possible, with permanent network stability. With the increasing size and complexity of machine networks, the correct design and real-time monitoring of the network and the downstream evaluation of diagnostic data becomes a challenging task. Even though most active components initially clear up minor errors on their own, an increased accumulation of errors can cause the network to malfunction or fail completely. This can be avoided by keeping a regular check on the network status using our Health Check Service. This will allow customers to foresee any errors that may come up and take preventative action to resolve them.

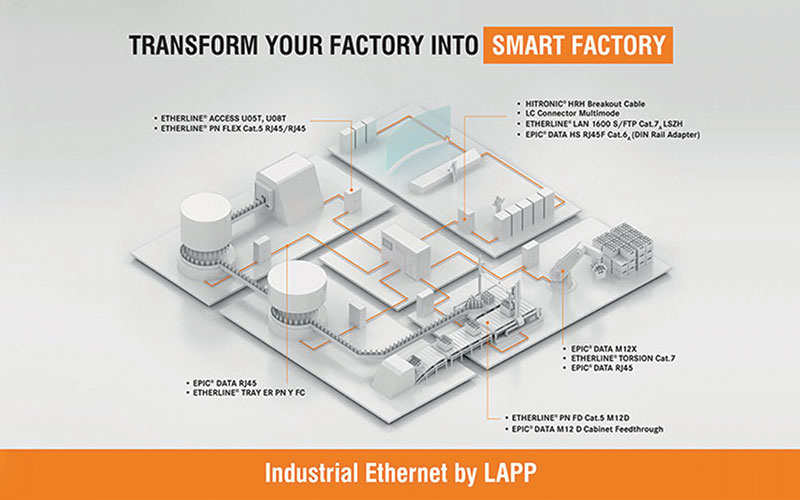

Our teams are also actively working on integrating Industry 4.0 concepts such as smart supply chains into our operations and developing high-speed connectivity solutions. We are also targeting to pilot smart factories in different locations of LAPP.

Also Read: LAPP Announces the Launch of ETHERLINE® GUARD in India

WCI: Please take us through some of the technology-driven products manufactured by your company.

GB:

- ETHERLINE® cables- Ethernet technology-based networks are playing an increasingly important role in industries. Our ETHERLINE® portfolio has been developed to offer comprehensive solutions for Ethernet networks. These products help to avoid downtimes and expensive breakdowns. The systems are made up of durable and robust cables and connection components for passive and active network technology to deliver an effective solution.

- HITRONIC® – Single Mode & Multimode Fiber Optic Cable- The demand for a fast and secure communication network is constantly growing. Fiber optic cables are now an indispensable and irreplaceable communication medium. Our HITRONIC® fiber optic cables transmit large data volumes at unbeatable levels of speed and security. They are a versatile range of cables for indoor and outdoor applications and can withstand the harshest environmental conditions.

- ETHERLINE® ACCESS- LAPP provides a range of network switches for Industrial Ethernet systems under the ETHERLINE® ACCESS brand. These products guarantee consistent quality with simple installation, high transmission rates in large temperature ranges and harsh operating conditions.

- ETHERLINE® GUARD- As part of the portfolio expansion of Industrial Communication products, we have introduced ETHERLINE® GUARD, a stationary and compact device from LAPP that monitors the performance of highly loaded ethernet cables at risk of failure and displays its current status which ensures seamless network connectivity.

- ÖLFLEX® CONTROL 277N and ÖLFLEX® CONTROL 277N CY- These are screened PVC power control cables rated 0.6/1 kV for tray exposed runs and wind turbine applications. Their application range includes industrial machinery and plant engineering. These newly launched products are cost-saving, allow for fast installation omitting protection systems and provide electromagnetic field screening along with 75 °C WET rating + sunlight-resistant rating for outdoor use.