wire China, launched in 2004, co-organised and developed jointly by Messe Dusseldorf and its subsidiary in China together with Shanghai Electric Cable Research Institute, has now become the leading trade fair of its kind in Asia, not only in exhibition scale but also for its international influence. Over the years, it has been playing an irreplaceable part in the industries’ trading and communication aspects. Together with industry players, wire China is committed to driving the development of China’s wire and cable industry, witnessing achievements and exploring opportunities. The trade fair is widely acclaimed among Chinese and foreign exhibitors and visitors alike.

The next show will be held during 24-27 September, 2014, at the new International EXPO Centre in Shanghai China. Worldly-renowned companies and leading brands, industry experts and industry players will meet here and brainstorm the latest developments and applications in the industry.

China’s urbanisation rate is estimated to exceed 55 per cent by 2015. The annual social fixed asset investment will top 30 trillion RMB, with that in infrastructure, e.g. power, construction, real estate, water conservancy, totaling more than 15 trillion RMB, bringing rosy market prospect and numerous business opportunities to wire and cable industries.

Smart cities: Development projects unveiled

During 2011-2015, China will invest 500 billion RM8 in the development of smart cities; projects in this regard involve 600-800 cities, with the market scale totaling 2 trillion RMB. The cable industry will witness new opportunities along with the development of smart cities.

Urban Rail transport: Booming growth

To date, 34 Chinese cities have got the green light for the plan of developing urban rail transport. Rail lines will exceed 4,300 km in total, doubling the current level. Thanks to the construction of rail transport infrastructure, further growth potential will be explored in the cable industry.

Smart grid: A market worth 1 trillion RMB

From 2011 to 2015, China will make great efforts in promoting the development of a unified strong and smart grid. Over the next decade, the huge project will create a market worth 1 trillion RMB for the power industry. The development of smart grid has become a key engine to fuel the global economy.

High speed railway: Dreams of gold

In the upcoming three years, 20,700 km of high-speed railway lines are expected to be constructed. The development of high-speed railway networks will reach peak in the period of 2013-2020. The annual investment in railway construction will be over 600 billion RMB, with the total amount 2.5 times that of the current level. Huge investment will guarantee further growth of cables used in mechanical and electrical equipment and railway signaling cables.

Concurrent Activities

As an important part of the conference, the organiser will release the report of the “evaluation of the competitiveness of China’s wire & cable industry enterprises”. With the aim to fire the enthusiasm of industry companies for enhancing competition ability, the top-ten most competitive companies will be awarded. Mean-while, in order to create more chances for communications, one keynote annual report, two technical forums and several technical seminars will be specially organised. The events mentioned above will enrich the theme topic and provide a platform for core enterprises’ participating industrial activities.

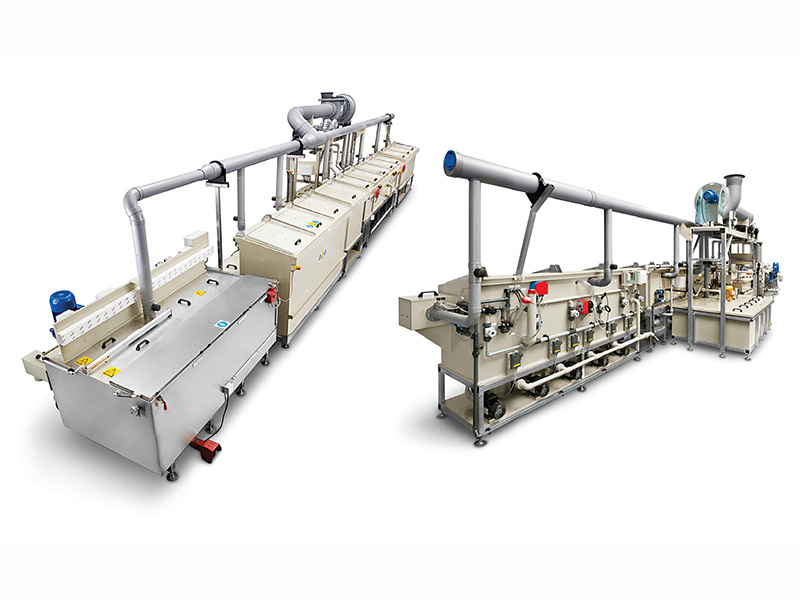

Candor Sweden AB: A unique partner for surface treatment of wire

CANDOR was founded in 1946. It specialises in cleaning and plating plants for wire and supplies chemicals for various applications.

The combination of its know-how in chemical processes and its advanced equipment for cleaning and plating of wire makes it unique on the market. It knows how to clean and metal coat wire.

CANDOR supplies both single- and multi strand systems for ferrous and non-ferrous materials, and all plants are tailor made after customer request.

At wire 2014, Candor introduces the COPPERJET plant, a newly developed high-speed copper coating plant for welding wires at high wire speeds with best possible quality.

A modular design makes it possible to satisfy a wide range of applications according to the customer’s request.

CANDOR Sweden AB also offers:

- ULTRASONIC & ELECROLYTIC Degreasing and Pickling plants

- CANDOJET HW – Patented Hot Water cleaning units

- Electrolytic Plating Plants for wires such as tinning-, coppering-, nickel plating-, silver plating-, galvanizing- for all sorts of wire materials.

Latest developments in Condat’s surface technologies for metal forming

At Wire China 2014 in Shanghai, CONDAT will present its latest developments in surface technologies for metal forming and present its extensive range of lubricants for Wire Drawing and Cold Rolling including:

- VICAFIL: The Industry’s most comprehensive range of wire drawing powders, wet lubricants, pastes, neat oils and greases.

- STEELSKIN: Advanced lubricant specialties for special wire-drawing applications.

- GALVASMOOTH: Smoke free charcoals for high zinc weight galvanised wires.

On the show, CONDAT will promote two innovative products:

- VICAFIL TS 7300 AD: New performance booster for borax coating

Based on water soluble mineral salts, VICAFIL TS 7300 AD is simply added to the borax solution. It improves significantly standard borax coatings providing a better coat weight control. In case of high moisture, it helps keeping the coating even and adherent with no need to process again the coils. Wire drawing is therefore much more efficient.

- VICAFIL SUMAC 5: new dry drawing lubricant – sodium soap based

VICAFIL SUMAC 5 has been designed for wire drawing at a very high speed. It offers the ability to work at higher temperature/speed whilst providing a high lubricating stability. It is perfect for stainless steel and high carbon spring wire, bead wire and steel cord applications.

Gauder Group at wire China 2014

POURTIER, SETIC and DALOO, members of the Gauder Group, are looking forward to welcoming visitors at booth W1E26 and presenting their comprehensive range of equipment and services:

• The POURTIER brand enlarged its offer with large equipment required for the production of submarine and umbilical cables and remains master buy with its heavy-duty stranders and cablers made in Europe for the production of all types of High Voltage and Extra-high Voltage Power cable, from overhead to insulated, AC type (using high quality Milliken conductor) or DC type (using large round compacted conductor or trapezoidal wires).

• The well-known SETIC brand provides high-speed double twist bunchers/stranders for the automotive industry as well as complete solutions to produce high quality LAN, special and control cables with enhanced performances (in one step or two steps according to product mix); all these machines are made in France and some of them are also manufactured by the Gauder Group China division with the same quality standards for direct supply to the Asian market.

• For cable producers wanting simple and reliable solutions for the production of power and communication cables at affordable price, DALOO is the unique choice proposing complete stranding lines and accessories whose design is based on European experience and the manufacturing is done in China following Gauder Group strict quality criteria

• ‘C2S’, the Cable Services & Systems division, whose turnover has been rising by 350 per cent for 10 years, takes care of all brand wire & cable production lines worldwide – this is the ideal partner to restore machine productivity and product quality.

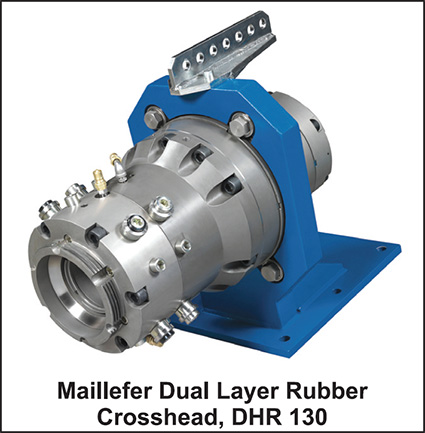

Maillefer to offer solutions for all demands

Maillefer’s new market concept with three production solution levels launched this spring at wire 2014 in Düsseldorf has been well grasped by the global market. There is a perfect match for each market situation – you can find the winning solution in low-end as well as in high-end categories in almost 20 applications.

Best value for different capacities and budgets

The new concept improves our possibilities to serve wire & cable and pipe & tube manufacturers with different capacity needs and investment budgets. The production solution levels are: /Enter, //Extend and ///Explore; and they vary in capacity, cost, automation, flexibility, product range and space and maintenance requirements. The widest services in the industry are available as an option for all levels.

Solutions for all demands

/Enter is a compact quality solution for more sustainable production. It is ideal for those searching for an affordable investment that is easy to start and maintain in different production environments.

//Extend is a lean and proven production solution for changing market needs. Its good upgradability and versatile product range guarantee a technical fit for the future.

///Explore is the royal road to demanding deliveries with the lowest total cost of ownership. It is a high output solution to explore the market in the front row.

Maillefer at wire China 2014

You can visit Maillefer’s booth W1F24 at wire China to hear more details about its new solution levels and product launches. Well worth mentioning is its new aviation cable production line which will be launched at the show as well as the High and Extra High Voltage Roundness Value Package.

You can have a hands-on experience on the Dual Layer Rubber Crosshead, DHR 130, High Voltage Triple Layer Crosshead, THX 70 150HV LR and the Telecom Triple Layer Crosshead, ECH 4/6 TL. All these components will be on live display.

How about arranging a visit to Maillefer’s new R&D and technology centre in Finland? This more than 1,500 sq m technology showroom is equipped with a pilot-scale vertical extrusion group for medium and high voltage cable production. It can produce real test samples. Other key pieces of equipment include the fibre optic and low voltage wire manufacturing line, clean room facilities and material purity control equipment.

Manufacturing solutions for optical fibre and cable production from Rosendahl Nextrom GmbH

Being at wire China is a must for all industry partners. And Rosendahl Nextrom brings along its manufacturing solutions for optical fibre and cable production. The Company specialises in Extrusion, Corrugation, Optical Fibre and SZ-Stranding. It supplies high-tech process technology along with customer service in a long-term partnership. One can now get manufacturing solutions for the production of Power Cables, Automotive Wires, LAN Cables, Coaxial Cables, Extrusion Crossheads, Preforms, Fiber Draw Towers, Fiber UV-Coating and Fiber Optic Cables from one source.

At wire China 2014, Rosendahl Nextrom will present the latest advancements and technology highlights, including new developments in high speeds, low voltage, medical wire through micro coax, VAD OVD preform technology, high performance draw technology and proof test and solutions for specialty fibre production.

Sikora has proven technology for quality control and cost saving

At the wire China 2014, SIKORA will be presenting a broad product range of innovations as well as proven technology for quality control and cost saving in wire and cable production.

Purity Scanner: 100 per cent pellet inspection

The highlight at SIKORA’s booth in Shanghai is the newly developed Purity Scanner. The Purity Scanner is a system for the online inspection and sorting of plastic pellets used for the insulation of medium-, high- and extra-high voltage cables, but as well for other applications such as the medical industry. Contaminated pellets are detected and sorted out, assuring that only pure pellets get into the extrusion process. The pellet inspection allows the detection of organic and metallic contamination inside the pellet as well as on the pellet surface, using a special combination of X-ray technology and an optical system. The smallest detectable particle size is 50 µm at a flow rate of up to 2,000 kg/h.

Preheater 6000 TC: Conductor preheating with temperature measurement and control

Another attraction at the SIKORA booth is the Preheater 6000 TC (Temperature Controlled), which represents the optimum solution for the controlled preheating of conductors and sets the basis for the production of a broad cable type array at highest quality. The system inductively heats up the conductor to the nominal value. An infrared camera measures the wire temperature at the outlet of the Preheater wheel. A control module supervises and controls the power setting of the device with high accuracy, assuring that the conductor temperature always has the specified temperature. The Preheater 6000 TC is available in three power classes (10, 20, 30 kW) for preheating temperatures of up to 150 °C (optionally 250 °C), for a product diameter from 0.32 to 2.8 mm.

Fiber Series 6000: Quality control of optical fibers in the drawing tower

The Fiber Series 6000 from SIKORA is sophisticated equipment for continuous online quality control of optical fibres in the drawing tower. The Fiber Laser 6003 measures the diameter of uncoated and coated fibres. Depending on its point of installation, it provides information on the position, vibration frequency, tension and spinning. The measuring principle ensures an accuracy of ± 0.05 µm. For the detection of airlines SIKORA offers the Fiber Laser 6003 Airline. In addition, the gauge heads provide information on concentricity and temperature of the optical fibre. The newly developed Fiber Lump 6003 Micro detects lumps and neckdowns on the optical fibre surface to 100 per cent. This is the result of the integration of six measuring axes. Shadow areas are eliminated and even the smallest faults from 5 µm height and 50 µm length are reliably detected.

Laser Series 2000 and 6000: High speed diameter measurement and lump detection

In addition to SIKORA’s successful diameter gauges of the classic-line Laser Series 2000, SIKORA offers the top-line Laser Series 6000. These diameter measuring devices are specifically designed for sophisticated customer requirements that exceed the classic demands in the wire and cable industry. The gauges fulfill all needs regarding highest accuracy, a variety of interface connection options and reliability for a quality control at its best during wire and cable production. The high accuracy allows in addition the detection of lumps and neckdowns. Three gauges are available for different product diameters from 0.2 to 78 mm.

Other technological highlights

In addition to the latest technological highlights, SIKORA shows among others the Centerview 8000e, which measures eccentricity, diameter and ovality of coaxial cables, LAN cables as well as automotive and installation cables. Moreover, SIKORA exhibits the 2- or 3-axis lump detectors Lump 2000 XY/T. For online quality control and optimisation of the material usage for increased productivity during the extrusion, SIKORA offers the well-proven X-RAY 6000 for single-layered cables and the X-RAY 6000 PRO for multi-layered products. The X-RAY 6000 series is interesting for the continuous measurement of the diameter, wall thickness, eccentricity and ovality in wire and cable production lines. In combination with the processor system ECOCONTROL 600, 1000 or 6000, an automatic control of the line is possible.

For quality control during the production of MV, HV and EHV cables in CCV-, VCV- and MDCV-lines SIKORA showcases the X-RAY 8000 NXT. The X-RAY 8000 NXT has been delivered now a thousand times and is recognised as an industrial standard. It is used for precise measurement of the wall thickness of all three layers (concentricity, diameter and ovality). Measuring values for centering and control are therefore available immediately after starting up the line.

TROESTER Group to share new developments at wire China 2014

TROESTER GmbH & Co. KG is a world leading supplier of machines and complete lines for the cable manufacturing and rubber processing industry, comprising CV Lines for XLPE and Rubber Cables, Silane Lines, Sheathing and Insulation Lines as well as the complete range of downstream equipment, such as winders, caterpillars, capstans and accumulators.

In China, TROESTER is represented by its subsidiary TROESTER Machinery Shanghai (TMS), which is responsible for the sales, after sales service and production for the domestic market.

At wire China 2014, TROESTER will present information and new developments in the field of:

- CCV and VCV Lines for MV, HV and EHV Cables up to 1000 kV

- Rubber CV and CCV Lines up to 35 kV

- CV Technology for production of HV Cables on CCV Lines

- Production equipment for submarine cables

X-Compound, the new company of the TROESTER Group, is specialised in the planning and construction of complete systems for the compounding of plastics with the process steps conveying, melting, dispersing, mixing and degassing.

X-Compound will join the booth and present:

- Kneader technology for the continuous compounding of HFFR (LSOH), PVC, XLPE, Semiconductive Materials and EPR/EPDM.

Automatic packaging solutions from Windak

Windak Group specialises in automatic packaging solutions for the wire and cable industry and has offices in Sweden, USA, Australia and Estonia.

Windak will participate at wire China 2014 in Shanghai and welcomes all visitors to its Booth B32, Hall W1.

Windak will participate at wire China together with Axjo company. AXJO is a well-known trademark and company in Europe that currently delivers spools and drums in polymer materials to all large cable works in Europe as well as to users in Asia, Brazil and Africa and now it has a production factory in North Carolina, USA.

At wire China 2014, Windak will present the latest information about its new products, Quickpack QP3 and FC5 Coilers. Information about Windak’s other products, such as Spoolers, Coilers, Rewind systems, Payoffs, Take-ups and Accumulators, will also be presented.

Quickpack is a fully automatic cable coiling and packaging machine. Its concept is based on absolute simplicity and maximum output. It has been designed to accommodate a range of product diameters up to 7mm with maximum speed up to 8 coils per minute!

The FC-5 Coiler is a versatile and user-friendly fully automatic coiler. It can hold the coil together with stretch wrap, a binder material or strap, making it truly the most multi-purpose coiling machine available. It can handle a wide range of cables from 3 to 25mm (0.12”–1.0”) diameter and coil size up to 480mm (19”).

Measuring and control solutions from Zumbach

Zumbach Electronics will be available at booth number W1F21 at the wire China show, where it will give detailed information about its wide range of measuring and control solutions for process monitoring, quality control and cost-effective production.

Its China team looks forward to providing information about the Company’s complete product range, which includes:

Sensors

- Its new DC and high frequency AC Spark Tester generation with local BAE 2 SP control and display unit accurately maintains test voltage under any conditions including highest capacitive loads.

- New, advanced KW TRIO fault detectors with local BAE 2 KW control and display unit.

- New 1, 2 and 3 axis diameter gauges for any cable and wire and any budget.

Besides the complete line of ODAC laser diameter gauges, new models with special beam geometry, fault detection function and high scan rate will be exhibited.

- MSD gauges diameter and ovality with “Multi-Source Device Technology”.

- The advanced ODEX concentricity and diameter gauge for wire extrusion. Fully non-contact, based on magnetic and laser technology.

- New ultrasonic wall thickness and eccentricity scanners of the UMAC RZ series with quick and easy adaptation to cable diameters and space-saving integration.

- Unique PROFILEMASTER profile and shape measurement systems using light section principle and machine vision.

Data Acquisition, Processing and Display Units (Processors)

- Modular high performance USYS IPC data acquisition, processing and display units.

Complete Measuring and Control Systems

- RAYEX D series: X-Ray measuring and control system for CV lines for wall thickness (3 layers), eccentricity and diameter/ovality for CV lines.

- WALLMASTER / UMAC – DIACAL Systems: Ultrasonic wall thickness and eccentricity systems for cable jackets and DIACAL option for fully automatic calibration and control.