Riding high on innovative technologies and sustainable manufacturing practices, Indore Composite Private Limited aims to further expand its market presence in 2024-25, while continuing to deliver high-quality products that meet the evolving needs of the fibre optic industry. By 2025, all facilities of the company target to primarily use renewable energy sources such as solar and wind. This was revealed by Mr. Ronak Sanghvi, Business Director – Telecom & Power Cables of Indore Composite Private Limited, during an exclusive interview with Wire & Cable India.

Wire & Cable India: As a supplier of cable protection solutions, how would you describe their importance in the production of optic fibre cable and how do you cater to the OFC segment?

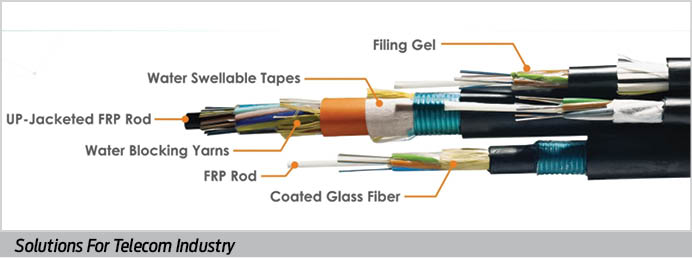

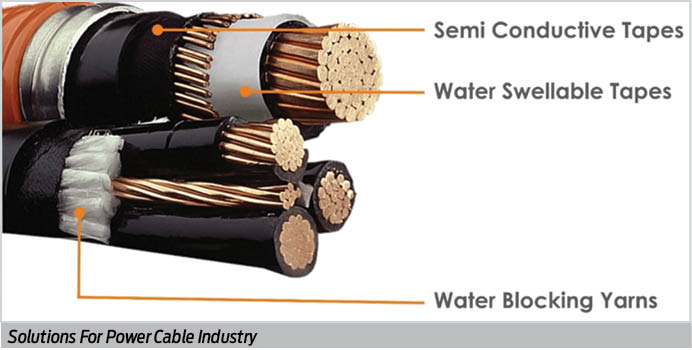

Ronak Sanghvi: Cable protection solutions are vital to the performance, longevity, and reliability of optic fibre cables. Indore Composite Private Limited offers a comprehensive range of essential products, including FRP (fibre reinforced plastic) rods, water-swellable (WS) tapes, coated glass yarns, thixotropic gels, and ARP (aramid reinforced plastic) rods. Our flagship product, FRP rods, provides the necessary tensile strength, anti-buckling properties and optimum flexibility, which are key factors in maintaining network integrity. WS tapes, yarns and gels protect cables against water ingress and offer anti-rodent protection, significantly enhancing durability in challenging environments. These solutions collectively reduce maintenance requirements, improve signal transmission quality, enable quicker installation, and ensure the robustness of fibre optic networks across various applications.

WCI: How are you positioned in the segment in terms of market share and production capacity?

RS: Indore Composite Private Limited is a pioneer in UV pultrusion technology for FRP and one of the largest global suppliers of FRP rods, catering to leading optic fibre cable manufacturers, including Corning Incorporated, Furukawa OFS, Prysmian, CommScope, SterliteTech, HFCL, Fujikura Group, LS Cables, ZTT and numerous other medium & small players. With an FRP production capacity of 8 million km annually, we align our operations to meet the demands of these industry giants. Indore Composite has maintained a dominant market position for over two decades, continually enhancing value creation through innovation and a customer-centric approach.

“The Indian fibre optic cable market is poised for significant growth, driven by rising demand for high-speed internet, the 5G rollout, and digital transformation.”

Our manufacturing facilities are equipped with cutting-edge technologies, including proprietary UV pultrusion processes, automated production lines, and AI & machine learning quality control systems. This set-up allows us to efficiently produce high-quality products with a lower environmental impact, setting us apart from competitors. Indore’s WS tape capacity stands at 12 million square meters, glass/polyester yarn capacity at 4,000 MT and gel capacity at 6,200 MT annually. Our multiple local & global manufacturing and warehousing facilities offer unmatched supply security, ensuring on-time delivery even in the most challenging situations.

WCI: How unique are the cable protection solutions used in optic fibre cables compared to those used in other cables?

RS: The cable protection solutions used in optic fibre cables are highly specialized compared to those in traditional copper or electrical cables. Our FRP rods are specifically designed to provide high tensile strength without adding significant weight, crucial for maintaining the flexibility and lightweight nature of fibre optic cables. Since these cables often run parallel to electrical cables, the dielectric nature of all components inside is critical. Our UV pultrusion technology, which uses UV light instead of conventional thermal methods, not only enhances product quality but also reduces the carbon footprint by 35 percent, making it both high-performing and eco-friendly. Unlike traditional steel wire reinforcement, which risks corrosion, our FRP composite rods eliminate this issue, providing superior performance.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

WCI: Who among the optic fibre cable manufacturers use your solutions? Please discuss the distinct results your solutions helped them achieve.

RS: Indore Composite has been a trusted supplier to the world’s leading optic fibre cable manufacturers, including Corning Incorporated, OFS (part of Furukawa Electric Company), Prysmian, CommScope, Sterlite, and AFL. Our FRP rods and protection solutions have enabled these companies to achieve superior cable performance with reduced signal loss, enhanced cable robustness, increased fibre count, and improved environmental resilience. By integrating our products, these manufacturers have seen significant improvements in the mechanical and environmental properties of their cables, allowing them to set new benchmarks in quality and reliability in global markets.

Our consistent quality of glass yarns, tapes and gels ensure better efficiencies and higher line speeds at customer’s production line, thus reducing scrap generation and downtime. Our precise manufacturing enables us to adapt to the unique cable production lines of our customers. Product customization and co-development initiatives with customers, led by Indore’s R&D team, is a key differentiator and strength, which makes Indore the most preferred supply partner.

WCI: What technology do you majorly rely on to manufacture products? Please give details about your quality control process which you adopt to ensure reliability and performance.

RS: Indore Composite relies on its proprietary UV pultrusion technology to produce FRP rods, using UV light to cure resins, which enhances mechanical properties and significantly reduces the carbon footprint compared to traditional thermal curing methods. We also employ advanced compounding techniques for WS tapes, gels and ARP components, ensuring consistent quality and performance. Our quality control processes include rigorous testing protocols such as tensile strength tests, environmental aging tests and signal attenuation checks, which ensure compliance with stringent industry standards. All our plants are certified with ISO 9001:2015, 14001:2015 and 45001:2018, while our R&D laboratory is NABL certified, which validates our robust quality management and testing systems. We continuously invest in automation, digitalization and Industry 4.0 technologies, integrating AI and machine learning at all quality checkpoints to minimize human error and ensure consistent product quality to our valued customers.

WCI: How do you source raw materials and what challenges do you face in the process?

RS: Our raw materials, including high-quality glass fibres, specialty resins, non-woven fabric, additives and coating materials are sourced from reliable world-class suppliers known for their consistency and quality. The main challenges we encounter include price volatility, raw material availability and logistics disruptions. To counter these challenges, Indore Composite has established a diversified supply chain and maintains strategic reserves of critical raw materials. By partnering with both local and international suppliers, we ensure a robust supply chain that is insulated from regional and global disruptions such as shortages and logistical challenges, ensuring uninterrupted production and consistent quality.

WCI: How sustainable are your products and how do you ensure it?

RS: Sustainability is a cornerstone of Indore Composite’s operations. Our UV pultrusion technology reduces energy consumption and emissions compared to traditional thermal processes, cutting the carbon footprint of our FRP rods by 35 percent. By 2025, all Indore facilities will primarily use renewable energy sources such as solar and wind. We are committed to carbon neutrality by 2030 and have partnered with organizations such as CDP, EcoVadis and Deloitte to validate our sustainability efforts against SBTI standards. Our new product development focuses on recyclable & eco-friendly materials, and we adhere to stringent environmental management standards. We are also exploring the use of bio-based resins and ensuring zero waste to landfill as part of our ongoing sustainability initiatives.

Also Read: Impact of Global Regulatory Changes on the Cable Industry

WCI: How do you view the Indian fibre optic cable market in terms of growth and product diversification? Where do you see yourself in 2024-25?

RS: The Indian fibre optic cable market is poised for significant growth, driven by rising demand for high-speed internet, the 5G rollout, and digital transformation. As one of the global leaders in providing cost-effective solutions for both domestic and export markets, India’s telecom sector is expected to see multi fold growth in the next five years, boosting demand for fibre optic cables and related products. The restart of the BBNL BharatNet project will provide a major boost to Indian manufacturers and the entire fibre optic cable value chain.

We anticipate tremendous opportunities for product diversification, especially in advanced cable protection solutions tailored for next-generation networks, including data centers, smart cities, 5G, and defence applications. By 2024-25, Indore Composite aims to further expand its market presence through innovative technologies and sustainable manufacturing practices, continuing to deliver high-quality products that meet the evolving needs of the fibre optic industry. Our commitment to innovation and customer satisfaction will drive our growth and maintain our leadership position in the market.