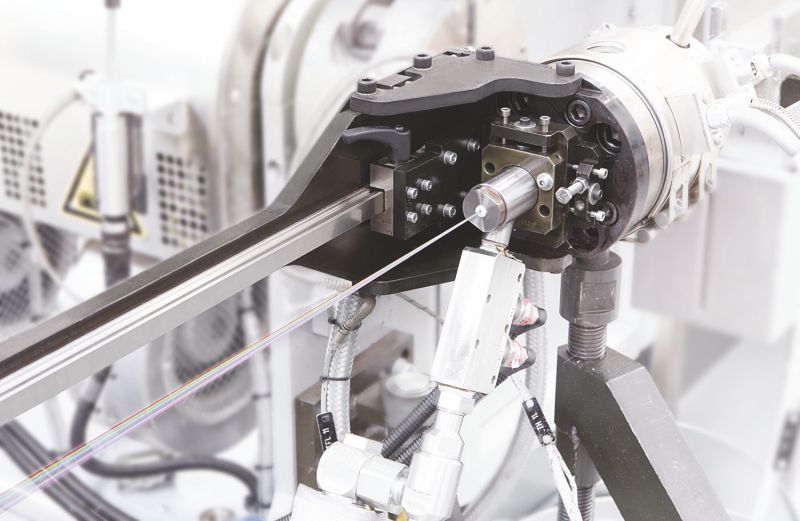

The Rosendahl Nextrom RX 5 crosshead with linear guiding is optimized for secondary coating lines. This works for both dry as well as for jelly-filled applications.

March 31, 2015

Rosendahl Nextrom’s RX 5 crosshead is specially developed forfiber optic cable applications. During the extrusion process, a high degree of reproducibility and constant product replication are core values for Rosendahl.

The Rosendahl Nextrom RX 5 crosshead with linear guiding is optimized for secondary coating lines. This works for both dry as well as for jelly-filled applications. It is comprised of a fine tuning centeing unit and a jelly unit for bubble-free jelly filling. The specially customized and adjusted needle supports the required precision during the extrusion process.

The loose tube trend shows that small-sized products are more and more in demand. And smaller products require a thinner wall thickness. With a wall thickness of 0.15 to 0.3 mm, the RX 5 crosshead meets the targets with precision. Even at geared line speeds of upto 1000 m/min, the product keeps its shape and required properties.

Rosendahl Nextrom has developed additional tools, like the trolley with a heating zone and special crosshead fixing. This supports product centricity and keeps the crosshead fixed at the same position.

The crosshead unit is easy to handle and has proven its reliability. If you wish to see a real life example, please visit the company in Pischelsdorf, Austria. In the local Technology Center, the loose tube line is available to be observed during production and interested parties can bring along their local material and individual recipe for tests on Rosendahl Nextrom’s laboratory line.