////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// Sanjeev Vyas*

As we are well aware that modern civilization depends upon the electricity and flow of electricity depends upon the cables. Hence cables are the backbone of any electrical distribution network. There are numerous brands of electric cables available in Indian market for the purpose. Everyone is claiming the compliance of it to specific standard specification but many times such claims are not true. While selecting the cable for particular application, emphasis must be on the quality as annual running cost plays a vital role besides safe functional performances.

As we are well aware that modern civilization depends upon the electricity and flow of electricity depends upon the cables. Hence cables are the backbone of any electrical distribution network. There are numerous brands of electric cables available in Indian market for the purpose. Everyone is claiming the compliance of it to specific standard specification but many times such claims are not true. While selecting the cable for particular application, emphasis must be on the quality as annual running cost plays a vital role besides safe functional performances.

In this article, an attempt has been made to make end user understand that if the cables are not selected with caution then how it leads to direct financial loss in terms of excessive annual running cost and creating unsafe conditions.

Loss occurred to the nation is substantial in terms of excessive energy consumption by using substandard cables.

In general, aluminum and copper constitute more than 70% of the total cost of a cable. Keeping in view today’s market scenario, drastic rising trend of aluminium and copper prices can be seen since last few years.

This has added to the serious problem of supplying sub-standard cables nowadays. Manufacturers of cable are tempted to cut corners and use lesser copper or aluminium than it is required and also by making the conductor with impure or recycled copper or aluminum, tendency of cable manufacturer is to reduce overall input cost.

Cable standards specify the maximum conductor resistance. Practices like drawing down lesser diameter of the wires or use of impure/recycled material reduces the considerable amount of input cost of copper/aluminum.

With reduced aluminium and copper components, cables are being provided with cheaper prices. Many times it is surprising to notice that cables are being supplied at prices even lesser than required raw material cost.

Defects caused due to under-rated, substandard cable has serious affect in form of direct money loss in terms of excessive power consumption besides overheating and reduced level of safety in electrical system network.

In general as far as functional performance is concerned, such serious defects cannot be judged during buying or installation of cables at consumer end. As LV cables are designed to operate at 1100 volts but in actual conditions being operated at system voltage of 415 volts in India.

Functional performance may be seen satisfactory for the years as such during the operation. Certificate of compliance is being issued to the cable brands on the basis of functional performances but unfortunately the losses caused in terms of excessive annual running cost on account of higher energy consumption are being ignored by the end users, which is quite substantial.

In Europe, Public Warning Notices about such unsafe cables are being published by authorities like BASEC (British Approval Services For Electric Cables) to assist the public safety and to create awareness of such unsafe and noncompliant cables. But In India we are lacking with such approach and awareness.

With the findings of a case study, an attempt has been made in this article to address it to the end user as how annual running cost increases and excessive energy losses occur due to use of substandard cables.

Case Study

For a particular electrical system following were the system parameters:

System Voltage: 415 V, 3 phase, 4 wire system

Load Current = 160 amps

Route length = 620 meters

3.5C x 150 sqmm cable with aluminium conductor and XLPE insulation was selected for the operation and there were two cable suppliers for this:

Supplier A @ Rs. 350 per meter

Supplier B @ Rs. 300 per meter.

Cable of “Supplier B” was selected as it was cheaper.

On investigation, it was noticed that actual size of cable of Supplier B was 20% lesser i.e (120 sqmm instead of 150 sqmm). Overall diameter of cable was matched to 150 sqmm with increased thickness of insulating material since input cost was lesser hence cable was supplied at cheaper prices.

Such defect could not be noticed during operation as recommended size of 150 sqmm with rated capacity of 255 amps was selected to operate at 160 amps (65% of rated capacity) and 20% underrated cable did not caused any immediate functional issues hence operational performance was seen satisfactory somehow.

Excessive Electricity Bills

Now let us understand it by following calculation, how it has impacted our pocket in terms of excessive electricity bills. First of all, we have to calculate Financial Running Cost Constant Kf in standard conditions.

Kf (Standard) = Total amount in term of energy losses in 3 phase system

Kf (Standard) = 3 Phase Energy Loss X Unit Rate

………………..= 3 x (I)2 x R x t x Unit Rate

I = rated current rating of cable in amps

R = AC resistance at operating temperature in ohms/km

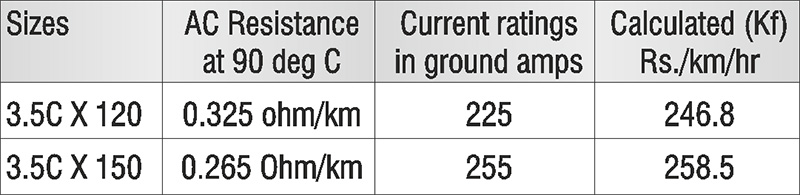

Values of rated currents & AC resistances are normally given in manufacturer’s catalogue and shown below for AL/XLPE cables for ready reference for particular sizes of cable used.

Unit Rate is taken as @ Rs. 5/- KWH

Unit Rate is taken as @ Rs. 5/- KWH

Kf (Standard) as calculated above are based on following assumption:

• Cables are to be charged at rated current

• Route length of 1 km

But in actual practical conditions, load current is lesser with varied route length. Hence Kf is required to be calculated at site conditions and calculated as below.

Kf for particular installation

= X2 x Kf (Standard) X Route Length in km

X = Actual load current / rated current of cable

X for 150 sqmm = 160/255 = 0.63

X for 120 sqmm = 160/225 = 0.71

Since for particular installation:

• Actual load current was 160 amps

Hence calculated values:

Kf for 120 sqmm = (0.71)2 X 246.8 X 0.62 = Rs. 77.1 per hour

Kf for 150 sqmm = (0.63)2 X 258.5 X 0.62 = Rs. 63.6 per hour

Now, Initial Cost (amount spent to buy the cable)

Supplier A Cable = 350 X 620 = Rs. 217,000/-

Supplier B Cable = 300 X 620 = Rs. 186,000/-

Total amount saved by buying cable from Supplier B as compared to Suppliers A:

Rs. 217,000 – Rs. 186,000 = Rs. 31,000

Energy Consumption

Amount spent in term of energy consumption in case of Supplier A cables used for particular application for one year:

63.6 X 20 X 30 X 12 = Rs. 457,900 (assuming 20 hours operation in a day)

Amount spent in term of energy consumption in case of Supplier B cables used for particular application for one year:

77.1 X 20 X 30 X 12 = Rs. 555,100 (assuming 20 hours operation in a day)

Total loss on account of cables from Supplier B:

Rs. 555,100 – Rs. 457,900 = Rs. 97,200 per year (Rs. 8,100/- per month).

Conclusion

There is loss of Rs. 8,100 per month on account of excessive power consumption in substandard quality cable. Thus, it will take only four months to loose Rs. 31,000, which we have saved one time on account of buying cheaper cable and after that, Rs. 8,100 per month would be a punishment for buying substandard/cheaper cable for a lifetime. Hence the cable, which has been purchased today at 10% lesser price one time may become 20% costlier for a lifetime if proper attention is not given to the quality of cables.

* Sanjeev Vyas is having B. Tech degree in Electrical Engineering with over 23 years of experience in the field of testing, design and development of electric cables and presently associated with Havells India Limited with cable division at Alwar (Rajasthan) as Dy. General Manager – Technical.