FUHR GmbH & Co. KG, headquartered in Steinheim, East Westphalia, recognizes the growing energy demand and energy transition challenges as an opportunity and sees itself in an excellent position.

Our world is changing! The ever-growing demand for energy and the ongoing efforts to master the energy transition pose major challenges for all of us. The wire industry, especially the branch related to the production of rectangular magnet wires, is also facing new tasks. Not only the increasing demand for these wires have to be met, but also completely new requirements lead to new challenges for the magnet wire producers. For example, the carbon footprint in the copper sector is playing an important role. Due to the increasing electrification in the mobility sector, previously unknown requirements for product quality and process stability as well as the documentation of these factors are also being placed on manufacturers.

FUHR GmbH & Co. KG recognizes the growing energy demand and energy transition challenges as an opportunity and sees itself in an excellent position. FUHR analyzed the market a few years ago and found that it can be divided into two different sectors. On one hand, there are wires for the construction of large generators, transformers and motors. These wires are usually manufactured to order. Wire manufacturers need flexible machines that can be quickly converted to accommodate changes in wire dimensions. The second sector serves the production of winding wires for the drive motors in electric cars. These are produced in large quantities over long periods of time. When it comes to production, it is not about flexibility, but about process stability and thus the highest product quality.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

FUHR offers optimized machine concepts for both sectors. For the flexible production sector, FUHR’s portfolio includes 5-stand rolling mills in different sizes. These machines are designed to be as efficient as possible for the required dimensional range. The modular design of these systems allows only the power that is really needed to be installed. Mr. Volker Gerth, Managing Director at FUHR, knows that it’s not just about flexibility and efficiency. “The quality of the produced wire and the documentation of this quality is also important,” he says. For this reason, FUHR relies on specially developed measuring devices and software for logging and evaluating the measurement data for its systems. “This allows our customers to document the wire dimensions of each produced reel,” he adds.

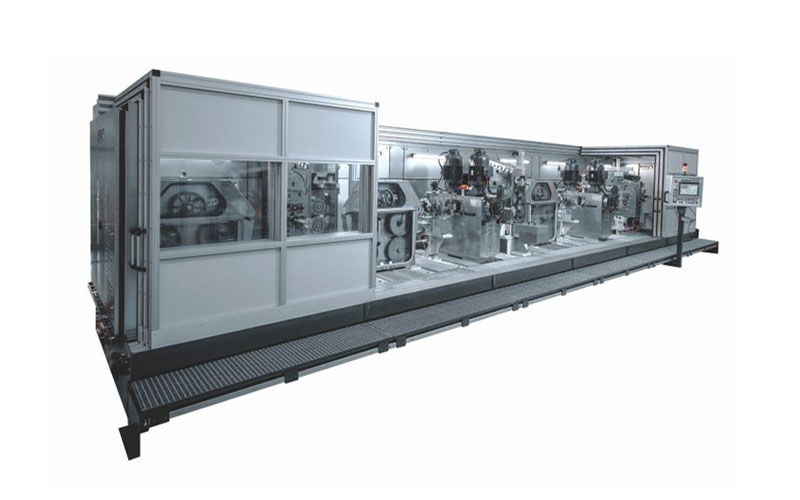

For the second sector, FUHR offers a compact machine, type IPU320. IPU stands for Inline Profiling Unit. This machine is designed for the continuous production of only a certain wire dimension and is usually installed directly in front of a wire insulation plant (enameling or extrusion unit). Due to its compact design, the IPU can also be integrated into existing systems. In this way, manufacturers of winding wires can meet the requirements of end customers with little effort. These winding wires, also known as “hairpin-wire”, must not show any damage, which is why wire forming and insulation are usually done in one line. The IPU320 is designed for wires up to 15mm2. This dimension is sufficient for the automotive sector. In order to be able to serve the growing market for the TMM (Transport & Mobile Machines) sector, FUHR has developed a larger version, the IPU500, in 2023.

Mr. Volker Gerth proudly reveals that the market agrees with the developments at FUHR. In addition to the almost 100 units of the IPU320 sold, the first IPU500 was also successfully delivered. And the order situation for 5-stand rolling machines is also excellent. For more than a year, there has been at least one 5-stand rolling mill in the FUHR plant at all times.

Visit Stand: Hall 9 / F26 at Wire Dusseldorf