“Setting the standard for precision and versatility, FENN wire lines are not limited to the rolling of natural edge flat wire. Square, trapezoid, half round, and many other specialty shapes can be rolled with the proper selection of FENN equipment,” says Ryan Cutter, President, Fenn LLC, in an interview given to Wire & Cable India.

Wire & Cable India: Tell us about the machine you have displayed here.

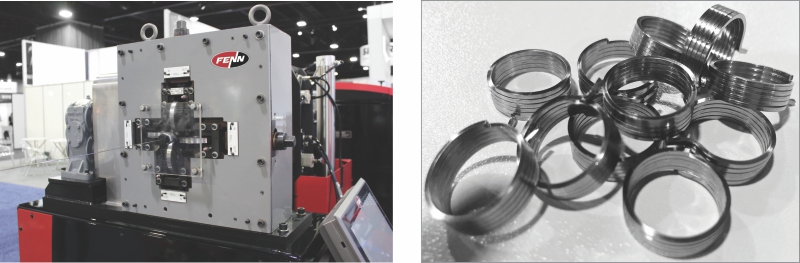

Ryan Cutter: With this wire shaping and coiling line, FENN provides an “all-in-one” solution to in-house wire processing. What we have displayed here is FENN’s 3U-HP power-driven Turks Head, which is feeding directly into one of our Torin spring coilers. FENN’s ability to integrate machinery enables users to shape wire and coil springs with a single line. The line produced clutch springs with square wire; however, a variety of spring applications which require shaped wire can be coiled using this line. The complete line eliminates reliance on outside vendors for either piece of the process. The line increases productivity by removing secondary processes. This is a demonstration of FENN’s ability to offer a complete line of metal forming equipment designed to meet customers’ specific requirements. The Turks Head is just one method of shaping wire. There are several other methods available from FENN.

WCI: What are the technical capabilities of this machine?

RC: The power-driven Turks Head can provide shaped wire at a very tight tolerance down to .0001 of an inch; and it can do so without the need for a pulling device. This particular machine has driven rolls, which is unlike a standard pull-through Turks Head; it therefore eliminates the need for a secondary pulling device, such as a capstan. Wire can go directly into the accumulator system and then into the spring coiler. Torin single point spring coilers, available in four, five, or six axes, are capable of handling wire diameters ranging from .076mm to 19mm. Torin’s FZ Series includes simplified, state-of-the-art controls with Torin’s “Spring Shortcut” spring generator program that allows an operator to produce a variety of springs and wire forms.

WCI: Could you elaborate on the applications of this machine?

RC: What we offer here with the Turks Head equipment is the efficiency to turn round wire directly into specialty shaped wire on a single machine. The other nice feature is that if you have a tight tolerance requirement, we can set up the machine with a vision system and the control system feedback to maintain a tight tolerance that you might not get from a standard wire supplier at a reasonable cost. Setting the standard for precision and versatility, FENN wire lines are not limited to the rolling of natural edge flat wire. Square, trapezoid, half round, and many other specialty shapes can be rolled with the proper selection of FENN equipment.

WCI: What are the other features of this machine?

RC: This machine represents the integration of two standard product lines for a specific application.

If you have a niche application and if it needs a tight tolerance, the addition of this system is a great way to eliminate scrap and to cut back on the amount of wire you receive that might be out of torque.