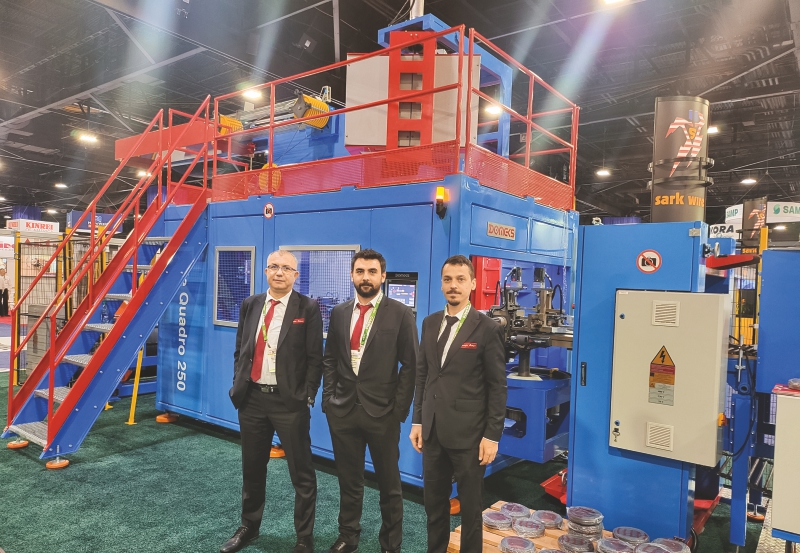

Domeks Makine Limited is a Turkey-based machine manufacturing company, whose products find application in high-speed coiling and reel packaging lines for cable manufacturers. Domeks has recently launched a new spooling and coiling line, which integrates some unique features that are still foreign to the market. In a conversation with Wire & Cable India, Mr. Ömer Yilmaz, Deputy Director General of Domeks Makine A.S., highlighted the key features of their new launch, Triple Quadro. Further in the interaction he also shared why they have concrete expectations of the new launch’s success.

Wire & Cable India: Congratulations on the new launch; please tell us about your new machine’s key features and advantages.

Mr. Ömer Yilmaz: Thank you very much. Our latest model is called Triple Quadro, and we are offering this machine in different sizes according to different types of cables and products. It is the fastest of all our lines till now, which is also one of the USPs. It can easily achieve 8 coils per minute for 100 meters wires, and for shorter lengths, ranging from 5 meters to up to 25-30 meters, it can easily produce the output radius of 10 to 11 coils per minute. Moreover, this latest model of ours is equipped to combine spooling and coiling modes on the same machine.

We can now do away with the stretching function, especially in European countries towards a sustainable and environment-friendly manufacturing practice. Plastic usage is becoming more restricted and with this model, we can now remove stretch usage and plastic film. The inclusion of a third hand helps us move out the coils or spools products without stretching them. In fact, we can take into consideration our customers’ requests and put the coils inside the carton boxes, or use other packing solutions like tying or strapping.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

“ Price-based competition is not justified for Triple Quadro. It combines spooling and coiling production on a single line without compromising with speed and quality. It manufactures six spools per minute and 8 coils per minute, for the bigger radii. ”

WCI: Could you elaborate on the automation features of this machine? How does this new machine place you in the market, against your competitors?

ÖY: This machine uses servo controllers, with almost all motors being servo-controlled, and position controlled. The technology gives us the ability to manufacture better layers and precise traversing control and good products.

In the market, this machine is among the first models to have application flexibility with lots of different products. It is why I mentioned that it is a significant advantage, the biggest in fact, is that we are able to combine coiling and spooling on the same machine. Its speed and function place it yards ahead of other technologies on the market, and there is no other line that works spools and coils together. The manufacturing capabilities are also great, as in spool mode it manufactures up to six spools per minute, and in coil mode up to 8 coils per minute, for the bigger radii.

Price-based competition, in our opinion, is not applicable to this machine. It is not justified for a machine with such unique features and capabilities.

Also Read: KLJ Group: Largest Manufacturer of Plasticizers & Polymer Compounds in South Asia

WCI: What kind of market response do you expect in the first year of launch? How many orders of this machine are you expecting?

ÖY: We are already receiving good feedback from the market and have concrete reasons to expect good order numbers since the machine enables high-speed production and has applications for inline operations in the US market as well. The inline operations are not common in Europe but in the US they are a normal occurrence. Our machine’s features have been successful in earning regional interest and we have been getting queries.

Overall, we have good expectations for this machine for this year.

“ It has been our observation that the Indian market is greatly inclined towards quality, and fast production, which are the defining features of this machine. ”

WCI: We recently met your colleague at an exhibition in Mumbai, and it was clear that the market is responding favorably to Domeks. What are your plans for the Indian market going forward?

ÖY: It has been our observation that the Indian market is greatly inclined towards quality, and fast production, which are the defining features of this machine. Hence, we are naturally expecting a positive response from the market for our launch.

Moreover, in the Indian market, especially the cable industry, the selling rate for exports is increasing day by day, majorly to European and the US markets. The market competition becomes more cut-throat in terms of exports, and fast lines can easily become a determinant of a company’s success in foreign markets. Furthermore, our line can also be used to combine with the carton box applications, actively prevalent in the local Indian market. Summarily, our machine has a great future, based on its features and advantages, in both Indian and foreign markets.