Headquartered in Pavia di Udine, Italy, DEM is a provider of wire rolling technology, with capabilities in design, manufacturing and commissioning of:

- Rolling lines with 2 or 4-rolls stands for flat and shaped steel wire, with extensive knowledge in stainless steel as well as high C grades;

- Rolling lines with 2 or 4-rolls stands for flat and shaped copper or aluminum wire, as well as rolling modules installed in enameling lines;

- Rolling lines for cold rolled or stretched reinforcing wire, then used in welded mesh, lattice girders or columns;

- Calibration and heating lines for annealing of IT spring wire;

- Forming & filling as well as redrawing lines for FCW flux cored welding wire;

- Drawing lines of round wire;

- Electric switchboards as well as automation equipment;

- Unwinders, rod preparation units, wire polishing devices, coilers, spoolers and bar bundle facilities including tying and strapping devices complement the lines.

Besides Wire Up, DEM delivers full software controls, augmented reality together with advanced connection solutions allowing for remote commissioning and maintenance.

Additionally, DEM supplies cassettes and auxiliaries for CRLs and micro cassettes and tooling for drawing lines.

DEM Wire Rolling Technology makes extensive use of innovative technological packages to improve health and safety, enhance yield, reduce process costs, increase product quality, and boost profitability.

Product Portfolio & Application Areas

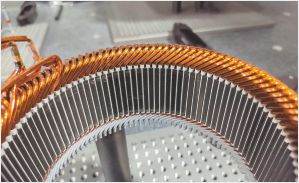

DEM supplies equipment and complete lines for production of copper wire starting from ETP, OF or other alloys as well as aluminum wire. The wire is then used in oil transformers, as CTC or insulated strip – in motors and generators, as enameled strips – in EV automotive, as enameled hairpins – in supply lines, as railway trolley wire and overhead cranes bars – in power distribution, as cables or clad wire. The copper alloys are used in electronics, as connectors and in the mechanical industry such as automotive, as brazing wire. DEM offers rolling mills, drawing lines as well as integrated facilities that include extrusion lines as well as annealing facilities. DEM rolling mills can be equipped with flattening and edging as well as 4-rolls precision stands, often called turk-heads, roll driven or with wire pulled by capstans, all in all in 5- or 7-stand configuration. Facilities for removal of dust from wire surface and perfect laying high-speed coiling complement the lines.

USPs

DEM rolling technology stands out of the crowd as it achieves:

- Higher speed (1200 m/min) by rolling, compared to drawing or extrusion; longer life of rolls, compared to dies (thus higher efficiency due to less maintenance and no need for extraordinary interventions).

- Perfect coiling of flat wire, inclusive profiles as small as 0.5 x 1.0 mm, guaranteed at the highest production speed.

- Outstanding tolerance: thickness : 0,002 mm – Width and corners: ½ standard with perfect transition from round to plane – guaranteed tolerance for the whole lots inclusive large lots (ie 10 t) due to negligible wear of tools.

- Dimensional and surface quality as demanded by the enamelling process for defect-free electric insulation.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

New Solution from DEM for Rolling Inline in Enamelling Lines

A newly developed stand-alone rolling module, very compact and versatile, to be implemented in existing and new enameling lines to reach perfect integration in such a ceaseless process, will be presented by DEM at the Wire Germany. A breakthrough for the fabrication of flat wire used as hairpins in e-mobility power engines.

Rolling vs Extrusion or Drawing Process

As of today, cold rolling process exceeds extrusion as to the rate of production output for small sections. On the other hand, excellent surface finishing and exact tolerances achieved by way of rolling wins over those obtained by other ways.

This applies to the fabrication of:

- Flat copper and/or aluminium in hardening grades for bare copper/aluminium strips, that are generally used in electrical connections and for mechanical application; CTC used in windings for power transformers; enamelled wire for transformer, motors, and generators; paper insulated copper/aluminium conductors, that are generally used as windings for electrical transformers, reactors etc.; glass yarn insulated copper strips, that are generally used in alternators, turbo alternators; glass yarn+polyester yarn copper strips, that are generally used in electric dry windings; polyimide film insulated copper strips, that are generally used for stator-rotor windings.

- Flat and square profiles in brass, bronze, nickel-silver and other copper alloys for electro-erosion wire, electronic wire, welding and brazing wire, special applications such as optics, etc.

- Thin strip in Cu OF or Cu ETP grades for copper clad conductors and ribbon for solar cells.

DEM Technological Packages for Profile Wire Rolling

The technological packages developed by DEM are a remarkable example of the way the company pursues innovation for the benefit of the wire industry.

Automatic Loading & Unloading of Spools:

The system is aiming at limiting damages to spools, in most cases due to manual mishandling. Preserving spools is very important in all those applications where the same spool filled by wire is used for further pay-off operations, downstream. Moreover, the system contributes to enhancing efficiency of operations.

Inline Cleaning of Tools by No-Contact System:

Keeping rolls clean plays a key role in the rolling process. It allows getting the end-product with a very clean and brilliant surface, limits the call for maintenance (removal of sticky particles from roll surface), promotes longer life of tools, and it is beneficial for final product accuracy. The non-contact cleaning system of DEM avoids any accumulation of dirt in the proximity of rolls, completely.

Stand Continuous Shift for Uniform Tool Wear:

By moving the overall stand sideways automatically with continual minimal shifting, the complete surface of rolls is going to be used equally over time, with uniform wear resulting along the full barrel of the roll. This results in the maximization of tools lifetime while minimizing their cost impact.

Fully Automatic Edging Stands:

The latest generation of edging stands allows accurate alignment between rolls with outstanding results as to corner radii accuracy. Additionally, all operations are made easier using memorized receipts, cutting time for threading the wire.

Wire Surface Polishing System:

As the call for a brilliant surface of end-product is increasing, DEM introduced a surface polishing system that is aimed at removing dust while getting glossy finishing of wire.

Inline Continuous Dimensional Check and Correction:

Automatic roll-gap control for no less than exact end-product geometry. This is obtained by latest generation electronic non-contact devices or by traditional contact type units, all sourced from primary brands highly specialized in the measuring technology, coupled with a software application specifically developed by DEM.

Perfect Traverse Coiling:

Even for tiny profiles as 0,5 x 1,0 mm processed at 1200 m/min! DEM also delivers equipment for precise cut-to-length bars and calandering (bending coilers) equipment for loose coils collected on tubular carriers.

Double Coilers with Automatic Wire Transfer:

The system allows the unloading operations of one coil, while another is processed avoiding unnecessary downtimes.

Wire Up – DEM’s Digital Platform for Non-Ferrous Wire Industry

Wire Up is a new tool specifically developed for the wire industry to get trends and track data while interfacing with ERP (Enterprise Resource Planning) and MES (Manufacturing Execution System).

This DEM’s IIoT platform ensures:

- Monitoring: check facts and figures about your machine, anywhere. Stay updated, always.

- Automatic alerts: get noticed of any malfunction, non-conformity or missed targets.

- Trouble-shooting: get helped and act promptly based on the know-how your operators built over time.

- Maintenance: take advantage of predictive maintenance thanks to memorized practices.

- Analysis: explore your big data. It’s easy. Do it anytime, anywhere. Find ways to improve.

- Process modeling: keep each and every task under control.

- Spare parts: manage inventories browsing 3D drawings.

The aim is to significantly reduce the time to market, increase repeatability and enhance plants efficiency and safety.

DEM in India

Aiming at boosting its activities in India, as of January 2020, DEM cooperates together with Rahul Jha, an engineer with experience in profile rolling technology.

DEM at the Wire exhibition in Düsseldorf: booth 11 G 42