The assumption that hardwiring will minimize wire installation costs turns out to be wrong

If you design or build industrial machines, you probably know all about hardwiring. It remains the most common way to bring power and signal to the machine because it offers a perceived savings in installation costs. But the cost savings are really just a mirage once you factor in the full range of wiring costs.

These installation costs obviously include time and materials—the cost of the wire, cable, accessories and labor. Less obvious is the fact that you’ll also incur hidden installation costs with their own labor and time-to-market considerations.

For example, many machines have to be disassembled for shipping and reassembled for startup. So you’ll have to hardwire parts of the machine at least twice. Then there’s the cost of errors. Field wiring errors are common, especially when local electricians, unfamiliar with the machine, are handling the wiring. At best, these errors can cause delays in machine commissioning. At worst, they can damage the machine. Finally, add in the cost of testing, which can be complex and expensive in hardwired systems.

For example, many machines have to be disassembled for shipping and reassembled for startup. So you’ll have to hardwire parts of the machine at least twice. Then there’s the cost of errors. Field wiring errors are common, especially when local electricians, unfamiliar with the machine, are handling the wiring. At best, these errors can cause delays in machine commissioning. At worst, they can damage the machine. Finally, add in the cost of testing, which can be complex and expensive in hardwired systems.

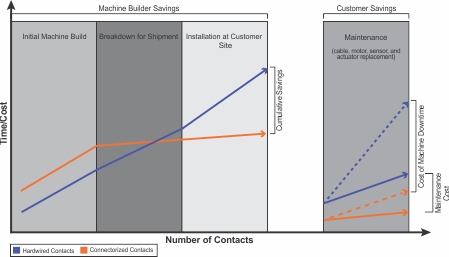

Keep in mind that the hidden costs will grow exponentially with the number of connection points on the machine. Fortunately, you can avoid all these costs through connectorization.

While connector components do require a bigger upfront investment, you will recoup that money and then some. Here’s how:

While connector components do require a bigger upfront investment, you will recoup that money and then some. Here’s how:

Connectors Enable Lower-cost Machines

Using connectors gives engineers the flexibility to create modular machines that are faster and less expensive to build. In this approach to machine design, common subsystems and

components can be pre-built, tested and stocked for installation. Many machines can be designed from reusable modules—including the control panels, junction boxes, populated cable tracks and motor assemblies. Sensor and actuators with prewired connectors are also increasingly available.

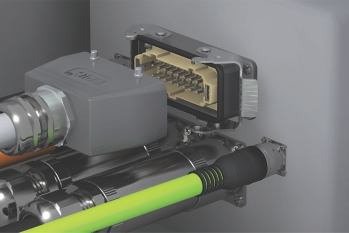

Connectorization provides the plug-and-play assembly that makes modular machines so attractive from a cost standpoint. Not only will the connectorized modules be easier to assemble, but they also ensure wiring integrity. For example, when multiple connectors can be mounted side-by-side, they can be keyed so that each cable connector only mates with the right receptacle.

One knock you’ll hear about connectors is that they can’t possibly cover all the scenarios addressed by point-to-point wiring, which is inherently a custom approach. Nowadays, however, electrical connectors address just about every power, control, signal and data application you can imagine.

One knock you’ll hear about connectors is that they can’t possibly cover all the scenarios addressed by point-to-point wiring, which is inherently a custom approach. Nowadays, however, electrical connectors address just about every power, control, signal and data application you can imagine.

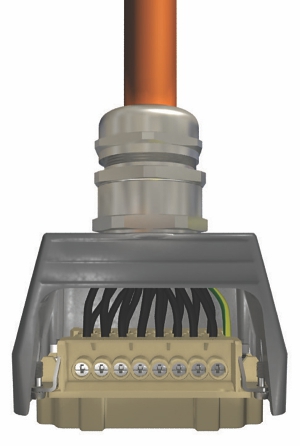

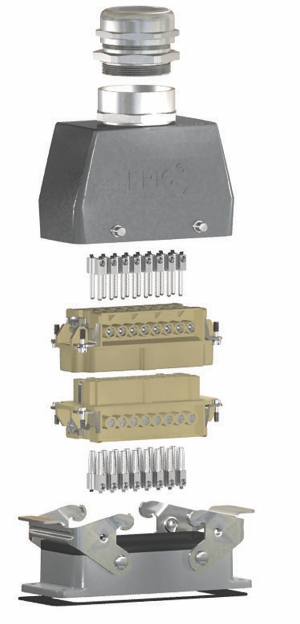

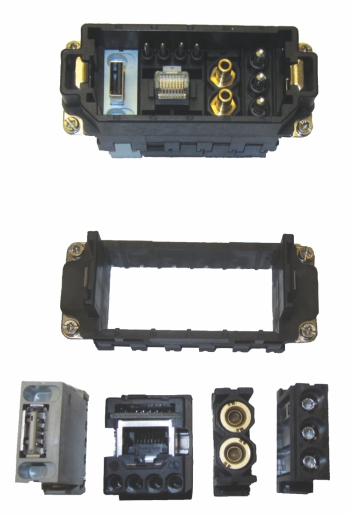

Some of these connectors are dedicated to specific electrical specification and have a fixed number of contacts. And custom modular connectors can meet specific machine requirements not addressed by off-the-shelf dedicated connectors. These modular connectors can pack power and control contacts, fiber optic contacts, pneumatic ports and data bus connectors into a environmentally-protected housing.

Machines Ship Faster

When new, large machines get ready to ship, they have to undergo at least some disassembly. At the very least, cables to and from the control panel will need to be disconnected for shipping. With hardwired machines, this extra step can be time consuming, expensive and fraught with error.

With connectorized machines, you simply unplug any cables from the panel’s bulkhead connectors. Wire routing and connections internal to the panel remain undisturbed. The same holds true for junction boxes, motor assemblies, sensors and data cables.

Quicker Commissioning

Once the machine arrives at its destination, all wires disconnected for shipment need to be connected all over again. In many cases, local electricians perform this crucial rewiring process using a set of wiring schematics. Since the electricians may know little about the machine and how it works, the rewiring process is notorious for costly mistakes and start-up delays. Machine builders sometimes minimize this risk by sending one or more factory technicians to complete the installation, and traveling technicians will drive additional cost.

Connectorized machines, by contrast, have a true plug and play startup process. The need to rewire the machine in the field, and the possibility of wiring mistakes are eliminated. No wiring mistakes means no costly troubleshooting or replacement of damaged components. For large, complex machines, installation and startup procedures that would take several weeks can often be reduced to a matter of days.

Connectorized machines, by contrast, have a true plug and play startup process. The need to rewire the machine in the field, and the possibility of wiring mistakes are eliminated. No wiring mistakes means no costly troubleshooting or replacement of damaged components. For large, complex machines, installation and startup procedures that would take several weeks can often be reduced to a matter of days.

Ongoing Savings

Machine buyers today expect and demand continuous, uninterrupted operation of their manufacturing and assembly lines. In large factory operations, even the briefest downtime can cost hundreds of thousands of dollars due to lost production. With a connectorized machine, replacement of a burned out motor, failed sensor or damaged component or cable takes place as quickly as the replacement parts can be installed on the machine. Put differently, connectorized systems remove any wiring-related downtime.

Machine buyers today expect and demand continuous, uninterrupted operation of their manufacturing and assembly lines. In large factory operations, even the briefest downtime can cost hundreds of thousands of dollars due to lost production. With a connectorized machine, replacement of a burned out motor, failed sensor or damaged component or cable takes place as quickly as the replacement parts can be installed on the machine. Put differently, connectorized systems remove any wiring-related downtime.

For machine builders, the ability to quickly ship, install and maintain machines represents an important selling point for their customers. While the upfront cost for connectors is higher, this one-time cost will be more than offset by the recurring and hidden costs associated with hardwiring.

Go Modular for Design Flexibility and Savings

Connectorization usually makes a lot of sense compared to hardwiring, but what if you can’t find an off-the-shelf connector that meets your technical requirements? That’s where modular connectors enter the picture.

Connectorization usually makes a lot of sense compared to hardwiring, but what if you can’t find an off-the-shelf connector that meets your technical requirements? That’s where modular connectors enter the picture.

Based on plug-and-play modules in standard frame sizes, modular connector technology covers a wide range of power, control and data connections. These include high voltage, high current, thermocouple, Profibus and Ethernet. Modular connectors also support hose-connected pneumatics up to 145 psi.

The main benefit of using modular connectors is that they combine the best attributes of custom and off-the-shelf products:

- Custom design flexibility. By combining power and signal modules freely, you get all the design flexibility of a custom product. Oftentimes, modular connectors will allow you to consolidate what would otherwise have been multiple connectors, saving panel space and reducing installation costs. Modular connectors can also be pre-assembled, fully tested cable assemblies—for even greater savings in installation and replacement costs.

- Off-the-shelf convenience. Despite their custom nature, modular connectors have lead-times similar to off-theshelf products, which helps you meet your delivery deadlines.

Source: LAPP GROUP