Established in 1854, Condat specialises in wire-drawing lubricants, industrial lubricants, greases, oils, tail seal compounds, gels, powders, solid/liquid dispersions, dry films, foams and admixtures/additives.

The Condat Group, which develops and produces chemical products and lubricants for all French, European and international industries, has an impressive product portfolio. It includes lubricants and products for processing, maintenance, iron and steel industry, underground construction and petroleum industry.

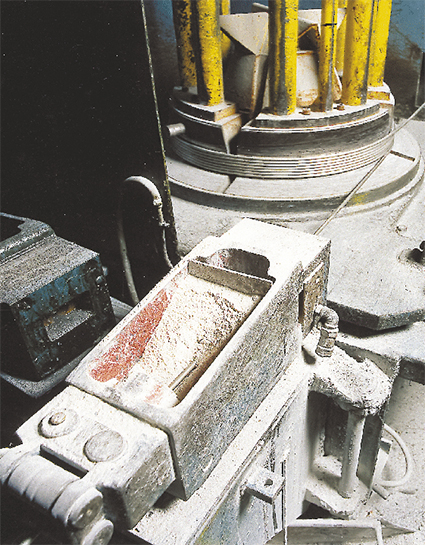

The Group is now a worldwide leader on the cold forming market – the VICAFIL range includes powders, soluble lubricants, oils, greases and pastes – and in everything that touches the underground construction field – tunneling, mining and drilling. To optimise product usage and to assist its customers in enhancing their productivity, Condat develops numerous assistance and service contracts in the scope of a package offer concept.

In 1989, the group was among the first 45 French companies to be certified for complying with the international standard ISO 9001.

The company’s desire to respect the environment is evident in the development of new product ranges including “biodegradable lubricants” and products meeting the latest regulation constraints.

The company has 500 workers and production units in countries such as France, the United States, China and Brazil; and 70 per cent of its turnover is made worldwide.

The Wire & Cable India (WCI) team recently interviewed

Mrs Sévérine Tilliette, Wire Drawing Product Manager, Condat, and Mr David Roughton, Sales Area Manager, Condat, to get an insight into the company’s corporate journey, product portfolio, research and development activities and core strengths.

Here are some excerpts from this highly informative interaction.

WCI: Condat is considered as a specialist in developing specific lubrication solutions. What are your comments on this statement?

WCI: Condat is considered as a specialist in developing specific lubrication solutions. What are your comments on this statement?

Sévérine Tilliette: Our exclusive R&D facilities maintain strong technological advances in all lubricating markets from metalworking fluids to metal die casting lubricants, and, of course, for wire lubricants. Condat’s offer includes a dedicated R&D laboratory, expert sales team, worldwide presence and after-sales support and services. This enables us to provide our customers with advanced solutions to meet and even exceed their requirements.

Following its ongoing improvement process and focusing on developing safer products both for humans and the environment, Condat moves ahead the latest legislative constraints to ensure product continuity.

WCI: What are your comments on the importance of using the right lubricants in the wire-drawing process? How can use of the right lubricant help wire companies achieve higher profits?

Sévérine Tilliette: By using the right lubricant for the customer process, companies can expect to increase the wire-drawing speed and, as a result, the productivity, without impacting their tool-life. Most of the time, these results can be achieved without increased lubricant consumption. Condat has also developed Borax- and phosphate-free lubricating solutions to minimise cost of waste treatment.

WCI: Tell us about the history and achievements of Condat?

Sévérine Tilliette: Condat is a 160 years old family-owned company. It started its business by selling natural fats for lubrication and has slowly but surely build up its expertise in all industrial lubricating fields. Condat is currently a world leader in wire-drawing lubricants; and, with three manufacturing sites around the world and a dedicated sales network, it can provide expert advice to its customers.

WCI: How do you ensure quality at Condat? What is the role of your R&D team in ensuring quality? Do you think you need to invest more in R&D?

Sévérine Tilliette: Condat is ISO 9001 certified. All our processes are monitored and controlled. We have an R&D team dedicated to the wire-drawing business. Not only does it work on new developments but also provides its expertise for solving problems on its customer premises. We also have a sales team with experience in wire-drawing industry. It can provide on-premises auditing and advice to improve customer performance.

WCI: What are your success factors? Where does your core strength lie?

Sévérine Tilliette: To put it briefly, the factors are R&D, international presence and expert sales team. These three factors allow Condat to offer the best product to its customer, everywhere in the world, with minimum lead time.

WCI: Tell us about your corporate journey in India. How has India performed for Condat in terms of demand and inclination towards adopting quality products? Are you satisfied with the performance of Condat in India? What are your future targets?

WCI: Tell us about your corporate journey in India. How has India performed for Condat in terms of demand and inclination towards adopting quality products? Are you satisfied with the performance of Condat in India? What are your future targets?

David Roughton: When we first started promoting our products in India, we concentrated on companies producing higher value-added products, such as stainless steel wires and high carbon wires. This has proved successful for us. There is a trend in the Indian wire industry towards investing in new and more modern machinery; this is increasing the demand for high-quality, wire-drawing lubricants, which is making more of the Indian market accessible to us.

WCI: Do you have any advice for the Indian wire industry regarding use of lubricants?

David Roughton: We believe that with the improvements we are seeing in the machinery/methods being used in India, the demand for high performance lubricants will increase. Rather than looking at the cost per kg of the lubricant used they should look at the benefits that can be reached by using a lubricant to match the performance of the new machinery.

We are confident that this can be achieved by the use of reliable, high-quality lubricants, such as the ones produced by Condat SA.