DuPont is a global innovation leader with technology-based materials and solutions that help transform industries and everyday life. In 2010, Celanese Corporation, a global chemical and specialty materials company, announced the acquisition of its two product lines, Zenite® liquid crystal polymer (LCP) and Thermx® polycyclohexylene-dimethylene terephthalate (PCT). Then in 2022, Celanese announced the complete acquisition of the majority of DuPont’s Mobility & Materials (M&M) business. In an interaction with Wire & Cable India, Mr. Nainesh Shah, Application Development Leader, E&E Clean Energy – India & Luis Zalamea Ph.D., Application Development Consultant, E&E Clean Energy – EMEA, talked about their new product, Hytrel® TPC HTR8856 having a high flexibility (low hardness) providing resilient cable performance.

Journey & Inspiration

DuPont and, later on, Celanese have maintained a long-standing presence in the cable coating market, spanning several decades. The driving force behind the involvement in this industry is the highly technical and specialized nature of the market, which places a high premium on technical expertise and reliability. At the same time, this market also values innovation, recognizing the importance of cutting-edge solutions in driving progress and growth. As a result, we have been able to establish ourselves as a trusted player in this field, leveraging technical competence and innovative spirit to deliver high-quality solutions to customers.

Unique Product Properties

Hytrel® offers a distinctive combination of properties that make it an ideal material for specialty cables, boasting a broad operating temperature range alongside exceptional flex fatigue resistance. Building on this foundation, recent developments have further enhanced Hytrel®’s capabilities with the addition of HFFR (Halogen-Free Flame Retardant) properties. Meanwhile, Santoprene® excels in terms of processability, backed by a proven track record of delivering long-term elastic properties and HFFR performance. Last but not least, Vamac® AEM presents a compelling option for applications requiring low smoke compounds with excellent thermal and chemical resistance, making it an attractive alternative for replacing fluoropolymers.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

Technology Advancements

The Celanese Engineered Materials Business has opened up new market opportunities for the wire & cable industry. A broad solution portfolio of high-performance thermoplastics and elastomers backed by Celanese science, technology and technical support, helps our customers to develop easy, reliable and cost-competitive cable solutions to meet the industry’s environmental & safety standards.

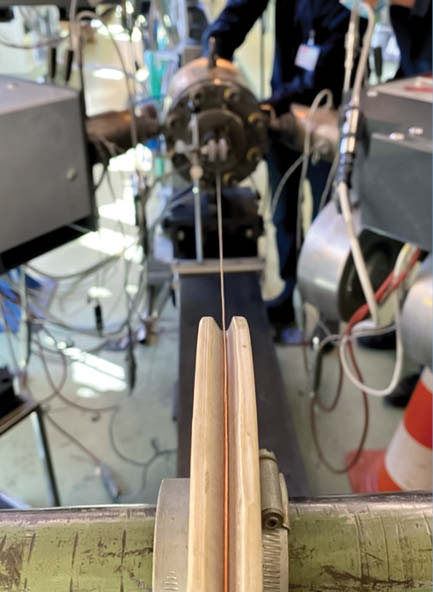

Hytrel® TPC is a unique hybrid thermoplastic elastomer, combining the flexibility of rubber and the strength and ease of processing of thermoplastic. Wire and cable extruded from Hytrel® TPC HTR8908 ECO-B have a high flexibility (low hardness) that provides resilient cable performance even after a lifetime of winding and unwinding the cable. Compared to the incumbent solution, the optimized density of this material will contribute to a total cost reduction for manufacturers. Hytrel® HTR8908 ECO-B solutions are produced with a minimum 50 percent biomass content by weight, using 2nd generation bio-based feedstock. Based on the biomass balance approach, Hytrel® TPC ECO-B enables carbon footprint reduction of up to 20% compared to comparable fossil-fuel-based materials. The mass balance approach used in the production of these materials is certified by ISCC+.

Our recently launched Hytrel® TPC HTR8856 is a medium hardness halogen-free flame retardant thermoplastic elastomer with very good flammability performance. It can be processed by thermoplastic techniques such as injection molding and extrusion. It provides strong and tough jacketing protecting the OFC inner structure, preventing impact from external forces, temperature, moisture, or UV resistance. It also provides balanced strength and excellent flexibility. Additionally, it has excellent flame retardancy and low smoke. Our material offers a wide temperature range (-40°C to 125°C), remains flexible, and is available in a natural color grade that’s easily colorable and UL62 FT-2 certified for cable use.

Also Read: Mixer S.p.A: Transforming the Cable Industry with Advanced Insulation Compounds

Mechanism in Place to Ensure the Quality

We have state-of-the-are manufacturing facilities across the globe, and we currently perform quality controls above and beyond the minimum levels required by the countries and regulatory agencies where we operate.

Clients & Target Markets

All major specialty cable producers are our customers, Prysmian, Nexans, Leoni, Huber and Suhner just to name a few. Specialty cables for transportation, auto, rail, marine, and telecom cables for data centers and buildings with the highest fire protection standards.

Ensuring Sustainability

We are pioneers in using sustainable raw materials to manufacture some of our elastomers. We use an ISCC+ certified mass balance approach to quantify renewable content in our products and are constantly expanding the portfolio of “green” materials that we offer.

Growth Target

According to recent market research and studies, the growth rate in India is projected to exceed 8%, a figure that is considered a conservative estimate, suggesting that the actual growth potential may be even higher. This indicates a highly promising market outlook, with tremendous opportunities for expansion and development.

USP: Sourcing Raw Materials

With a global asset footprint spanning multiple regions, we have strategically cultivated a diversified portfolio of raw material suppliers. This deliberate approach enables us to effectively mitigate risk by avoiding overdependence on a single region or source, thereby ensuring a more resilient and flexible supply chain. This strategic advantage is a unique strength that few companies can match, providing us with a competitive edge in the market.