A dazzling display of products and machineries from the wire and cable industry represented by over 12 countries was unveiled amid large gathering of visitors. Businesses, ideas, and leaders came together to discuss the future of the sector at the conference happening in parallel with the expo.

Cable & Wire Fair 2015 (CWF15), the first edition, organized by Tulip 3P Media Pvt. Ltd – the publisher of celebrated Wire & Cable India magazine, took off on December 3, 2015 at Pragati Maidan, New Delhi, India. The exhibition cum conference, spanning 3 days from 3-5 December, was inaugurated amidst cheers and much fanfare. Exhibitors from over 12 countries including India put their products, machineries, and technology on display for visitors. Over 10,000 registered visitors from India and overseas were seen active during three days of the show.

KEI Industries Ltd; Mr. Nirmal Saraf, MD, Nirmal Wires Pvt Ltd; Mr. Kamal Jain, Director,

KLJ Group; Mr. Parveen Kumar Jain, CMD, Tulip 3P Media Pvt Ltd and Editor & Publisher of

Wire & Cable India magazine and Mr. Priyank Jain, CEO, Tulip 3P Media Pvt Ltd

The show is set to become a premier wire and cable expo in India based on the tremendous positive response from the industry in India and beyond. It is centered at creating a consensus driven, growth oriented stage for the wire and cable industry in India. Exhibitors broadly included wire & rod manufacturers, cable manufacturers, machinery & equipment manufacturers for wire/cable making, consum-ables makers, spares makers for wire/cable making, etc.

A Long Awaited Show

Many companies from India and overseas exhibited at the show. Companies such as Aarti Steels Limited, Assomac Machines Limited, Bansal Wire Industries Limited, Carl Bechem Lubricants India Pvt Ltd, Danfoss Industries Pvt Ltd, Kkaplena Industries, KLJ Polymers & Chemicals Limited, Medek & Schoerner, Parovi Machines, SAMP S.p.a, Sarvasv Machiner, Supermac Industries India Ltd. etc. put their ensemble for the visitors. The exhibitors and visitors expressed their satisfaction over the arrangement and smooth conduction of the expo.

The show was inaugurated by eminent names of the wire and cable industry such as Mr. Anil Gupta, CMD, KEI Industries Ltd; Mr. Kamal Jain, Director, KLJ Group; Mr. Harry Prunk, Executive Board, SIKORA AG, Germany; Nirmal Saraf, MD, Nirmal Wires (P) Ltd.

Mr. Anil Gupta said, “The show and conference running side by side is always a boon for the industry where one finds a space for both displaying one’s product and exchanging knowledge with others. We welcome such show from our heart and wish it a huge success in times to come.”

Mr. Kamal Jain said, “We have been eager to see a show, targeting our industry, organized in the national capital. Cable & Wire Fair 2015 is sort of breather and we look forward to seeing this show grow from strength to strength in future.”

Industry to Witness Better Days

Speaking, at the inaugural session of CWF 2015, on the state of Indian wire and cable industry, Mr. Anil Gupta hinted at gradually improving state of affairs amidst plethora of government’s initiatives across the sectors accruing in increased demand of the wires and cables in times to come. He said, “The world economy, at the moment, is on the recovery path from the extended slowdown which started in 2008 and India as a country is all set to become a global manufacturing hub. With the Govt. of India initiating several programs like Make in India, there would be immense facilitation and consolidation of manufacturing in the country thereby making every industry more competitive. Initiatives like Smart Cities, Digital India, BharatNet, etc. are sure to take the demands of wires and cables to a new height.

“Indian wire and cable industry is doing well in terms of growing demands and we hope to continue growing by virtue of growth in telecom, renewable, and transmission sectors. Moreover, India’s power sector is growing at brisk pace, and with the government’s commitment to provide 24X7 quality power to all, the Indian wire and cable industry would witness huge demands in power cable segment.

“With industries like infrastructure, mining, construction, tourism & hospitality, the demand is to grow steadily. We see a lot of opportunities in the oil & gas sector with the substantial expansion in refineries and gas production plants in India. Metro railways have been a big booster for the cable industry for last several years. Initially DMRC took the lead, and now we are witnessing metro rail projects coming up in every major city across India which, in my opinion, will continue for next 20 years.”

Mr. Gupta feels that there is an increasing movement towards industry becoming more and more organized and becoming more quality and technology driven. He said, “Despite being a volume driven product, wires and cables have a lot technical specifications which have to be kept in mind. The Indian wire and cable industry of late has become quite quality conscious, and is set to witness a transformation towards more technological advancement in times to come. The expansion of automatic and innovative cost reducing manufacturing technology is increasing the productivity and quality at factory level.

“Moreover, over a period of time, the industry has moved from being unorganized to a lot more organized. We have seen that large players have come up more because of quality consciousness and other technological advancements in the industry, and vice-versa.”

Mr. Gupta opines that cable and wire sector is hugely diversified because of rising demand of energy and the sector is estimated to grow at CAGR of 15 percent year-on-year, although in last two years the growth has been more where the volume grew by almost 25 percent. According to Mr. Gupta, this kind of growth has been unprecedented and not seen in other electrical products. The demand is predominantly from intelligent electrical devices and growing digitization.

“If we evaluate the electrification plans of Smart Cities as per the Govt. of India statistics, nearly 94 percent households in urban areas have access to electricity, but not quality access with respect to adequacy, steady voltage, etc. The cities therefore should shift towards smart metering at the household level to stop the pilferage of power; towards establishing smart grids, and its integration with renewable sources. Also, the existing distribution system needs to be strengthened and power banking system systems should be put in place,” said Mr. Gupta.

Mr. Gupta stressed the need of green building and green transport for energy conservation view-point, and indicated that there will be massive commitment towards renewable energy after latest United Nations Climate Change Conference 2015, COP 21, where the stipulated contribution of renewable energy has set at about 25-30 percent. The renewable energy generation would be 36000 MW by the end of the 12th year plan.

Talking about the challenges the wire and cable industry recurrently faces, Mr. Gupta said, “The challenges include the management of input costs, the competitions arising out of Chinese and Korean imports, high rate of interest, infrastructure bottlenecks at roads and seaports leading in delayed transportation and shipment, etc. These are the issues that I think the present government is trying to look into.

“Export is a persisting challenge and companies in India have to make efforts in making ‘Made in India’ products acceptable and competitive to international customers in terms of quality. However, this is happening now, and some specific companies are making products up to global benchmarks. The Govt. has also announced some market focused and product focused schemes, and some interest subvention plan has also been announced in the EXIM policy to ease the banking credits and financing mechanisms.

“Challenges of course are there, but I am sure that our Industry is well poised to address these issues,” concluded Mr. Gupta.

The World is Watching

“Indian economy is potentially a very economy today,” said Mr. Kamal Jain, Director, KLJ Group, “and the world is watching. We are making attempts for growing, for taking a leap, but something or the other is holding us back. However, I am sure that with the continued effort and the law of nature lion would get its share in few more attempts and that India will have its share of growth.

Mr. Jain said that India’s current growth of 7-8 percent may need look too bad from the angle of developed world’s growth, but it’s not too good either for a developing country like India. However, continued and sustained effort to revitalize the economy, especially manufacturing sector, will surely pay dividends in times to come.

“When the economy growth happens, the infrastructure would be a pre-requisite – infrastructural growth would look up to economic growth and as a chain reaction infrastructure will catalyze further economic growth,” said Mr. Jain. “We are now sitting at excess capacity in the cable industry. But, the wire and cable industry is right on the threshold of potential growth and that would happen the moment we realize some growth in our economy.

“Polymer compounds probably are the biggest specialty contribution in the wire and cable segment after the commodities like metals such as copper. There are lots of advancements in the ways we perceive technology, the ways people buy compounds, and the ways people make compounds. We are gradually moving towards a market that realizes the significance of quality both when buying cables and buying compounds, hence leading to a more mature market.”

Mr. Jain also underlined the market today as more organized and being dominated by large players who contribute copiously to overall GDP. He said, “I think the top 10 cable manufacturers are contributing a GDP of almost Rs. 20,000 cr to Rs. 25,000 cr. Compounds and polymer consumption at 12-13 percent should be about Rs. 7000-8000 cr per annum for the cable industry which by any means is a good volume.

“To a good extent, we have been able to assure that requirements are met locally, domestically. The target for polymer industry and additive industry is to make sure that world class products are available. I think that KLJ has been largely successful in doing that. As a company we don’t only satisfy the requirements of Indian market, but we are also exporting our products to almost 80 countries around the world.”

“We are sitting on a challenging time where economy could have been brighter – not very bad right now, but definitely it could be much better. We have excess capacities to be fulfilled in the market, lots of projects clearances pending because of some govt. related issues, some taxation issues which the govt. is working on to resolve, etc. Once we get over these, things will start looking brighter,” concluded Mr. Jain.

Increasing Quality Concerns

Mr. Harry Prunk, Executive Board, SIKORA AG, Germany outlined the changing spectrum of technology preference and quality over a period of time, and opined that cost reduction and quality has remained central to the aspirations of the wire and cable industry across the world. He said, “It’s just as well that Indian companies are expecting continuous growth in the next 15 years with some expansion outside India. However, they are also right in conjecturing strong competition from global players, and the competition won’t be only on price front, but on technology and performance also.

“When I look back 40 years of the wire and cable industry, the measurement technique gradually moved away from human influence to concentrating more on optical devices to increase the product quality. The next step was people looking for reduction in cost and oversized wall thickness. And, today our focus rests on minimum material consumption with uncompro-mised quality.

“We can see this in all fields of the industry. We can, for instance, take the automotive industry where the wall thickness tends to become minimum to achieve overall lower weight for less fuel consumption. We have devised many technologies for that. However, the new challenge emerging in the automotive industry is to switch to aluminum conductor from copper conductor.”

Mr. Prunk also pointed to upcoming big growth in optical fiber business in India owing to growing consciousness towards digitization. “We have also seen big changes in optical fiber usages, especially in those countries where copper cable network was not so well established, thereby giving the opportunity to optical fiber business to grow. And, that market is huge and booming at the moment, especially Asian countries,” he said.

“Coming to power cable industry, we see a tendency away from nuclear power and coal based energy to renewable energy sources like wind and solar. For tapping the ocean wind power, we need quality sub-sea cables – longer production with less and less cable joints. At the same time, quality, reliability, performance, and a life time of 30-40 years have to be assured. All of that is only possible if we start not with the cable, but with the inspection of compound i.e. the purity of the material,” said Mr. Prunk outlining the new quality paradigm emerging from the requirements of renewable energy.

Stating further on the significance of compounds in making quality wire and cable, he stressed on the need to cut down on the sole reliance on supplier and go for some self inspection and quality check. “In the past, there was much dependence on the supplier; you couldn’t do something yourself. But, today there is plethora of ways through which you yourself can assure the quality of material thereby improving the quality and performance of your wires and cables. I am sure many of you have already invested in those quality inspection technologies,” said Mr. Prunk.

Concluding, he said, “There is a lot more to be done, especially on the power cable side where we see the growth is quite strong in next few years; there is a lot more to be achieved.”

Steel Wires: Strength & Security

Outlining the significance of steel wire industry in economy and in supporting the industrial growth, Nirmal Saraf, MD, Nirmal Wires (P) Ltd said, “When you talk of steel wires sector, I don’t see myself as someone who manufactures steel wires, but rather as someone who provides strength, security, and safety to public at large. How do we do that? As soon as you talk about steel, strength comes to your mind, and most of what we make provides strength to city infra, railways, tyre industry, conductors, etc. And, of course, we protect you by fencing – a lot of steel wire goes into it.”

“Steel wire industry is huge in India – today standing at 4 million tonnes a year. The industry landscape is studded by largely MSMEs, with very few large players, capable of competing with anyone in the world in terms of product quality and standard. The industry is also growing fast and the consumption of wires has doubled in past 9 years indicating a CAGR of 8 percent. Going forward, the way the Govt. is moving and the economy is looking up, we see this sector doing very well,” said Mr. Saraf giving an overview of the steel wire industry.

He continued, “However, a note of caution has to be sounded, though we are galloping ahead. The biggest problem that we foresee today is the availability of raw material, which is persisting from last seven-eight years.”

On the subject of protection of indigenous industry from imports, Mr. Saraf said, “Of late, there has been downturn in the commodity prices internationally and we have seen a clamor from producers of commodities like aluminum and steel for protection against imports in the form of tariff and non-tariff barriers. I personally feel that protection to the industry in general, in long term, will result in weakness if the industry is not left to fight against all odds and come out fine. We are sure to surge ahead, but we have to focus on quality and competitiveness, not on protection.”

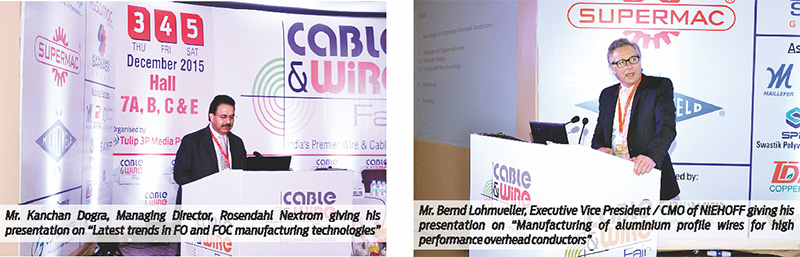

Conference: Panel Discussions and Technical Sessions

The conjoint holding of show and conference was hailed by many as rare and worth attending. The three days show was to witness three CEO panel discussions and three technical discussions, where first day saw two CEO panel discussions and one technical session. The first round of CEO Panel Discussion was on the broad subject of Indian cable market, growth opportunities and key challenges. The panelists were Mr. Anil Gupta, CMD, KEI Industries Ltd; Mr. Vijay Karia, CMD, Ravin Group; Mr. Abhishek Gupta, Director, Gupta Power Infrastructure Ltd; Mr. Sandeep Aggarwal, MD, Paramount Communications Ltd. Mr. Priyank Jain, CEO, Tulip 3P Media Pvt Ltd was moderating the discussion.

The second round of CEO Panel Discussion delineated on the subject of growth opportunities and key challenges for optical cable, renewable and other specialty cable market now and in future. The panelists were Mr. VK Bajaj, COO, Uniflex Cables Ltd; Mr. Avinash Ladha, Director, TDT Copper Ltd; and Ms. Nivedita Pandya, Director, Diamond Power Infrastructure Ltd. The discussion was moderated by Mr. Jasvinder singh, Managing Director, Supermac Industries (India) Limited.

Harnessing Opportunities, Mitigating Challenges

A distinguished panel, comprising acknowledged industry leaders, talked at length about how to sustain and motivate the growth of the Indian wire and cable industry.

The two-day conference, running parallel with Cable & Wire Fair 2015, saw its first round of CEO Panel Discussion (December 3) on the overarching subject Indian Wire & Cable Industry: Harnessing Opportunities, Mitigating Challenges. The panelists were Mr. Anil Gupta, CMD, KEI Industries Ltd; Mr. Vijay Karia, CMD, Ravin Group; Mr. Abhishek Gupta, Director, Gupta Power Infrastructure Ltd; Mr. Sandeep Aggarwal, MD, Paramount Communications Ltd.; and Mr. R. Ramakrishnan, Vice Chairman, Joint Managing Director & Group CEO, Polycab Group. Mr. Priyank Jain, CEO, Tulip 3P Media Pvt Ltd was moderating the discussion.

The session was brimming with insights, ideas, speculations and ground reality about the Indian wire and cable industry put forth by well-known industry leaders. The panel where looked buoyed at the rising demand across sectors and the Govt.’s investments, was also worried at the contracting private investments. The issue of credit availability and levying of reasonable interest rate on it were also seen appearing time to time during discussion. The growth of the industry was rightly identified as inseparably linked to the wellness of power sector; so expanding the generation capacity, revamping the transmission sector, and reforming the distribution were seen as essential concomitants of the industry’s growth.

The issue of protection and safeguards against imports, more so dumping, saw mixed responses, but was fairly supported by all. The new avenues arising from increasing proclivity towards non-conventional energy sources were duly noted, and the panelists urged the industry in unison to be ready for new commitments towards quality for such cabling requirements. Some were of the opinion that pre-qualification rules for imports be more stringent, while some suggested the significance of sooner implementation of GST laws for the good of industries across sectors. Telecommunication industry and its steady growth were also discussed in the light of revolutionizing digitization programs of the Govt. of India; massive investment by the state in this sector was considered as not only a boon for the telecom industry, but as a catalyzer of the whole economy.

Signs of Good Growth

“The demand in the cable industry is steadily growing across sectors. May be construction industry is currently little flat because of slowdown in real estate business; we are getting good growth from all other sectors otherwise,” said Mr. Anil Gupta, CMD, KEI Industries Ltd when asked to comment on the present state of the demand in the wire and cable industry.

On the question of how to sustain this growing demand in long run, he said, “The government spending on the infrastructure has to be maintained and even be increased to drive the growth of the industry. The sectors other than infra such as steel, cement, petrochemicals, etc., which are predominantly controlled by private investments, have to grow side by side. The biggest challenge today is that private sector either slow or unable to make new investments because most of the industries are grappling through overcapacities. This must not be the case in times to come.

“Moreover, we need protection from dumping and needless import. In spite of WTO rules, there are countries that protect their industries through various quantitative and qualitative restrictions. Our government should also do something of this nature to safeguard us from cheaper imports brewing unhealthy competition.

“As the wire and cable industry are strongly dependent on power sector, the reforms in the distribution sector will not only result in good demand growth for wires and cables, but also in huge reduction in pilferages and power losses. I think the Govt. should focus on distribution reforms by way of revamping the old distribution structures and also by putting up new ones in the untapped areas; both the ways the demand of wires and cables would surge.”

According to Mr. Gupta, quality remains at centre-stage ever for sustaining the demand. He said, “As an industry we should organize ourselves in a manner where we should not lower the prices by lowering the quality. Quality doesn’t win only domestic consumers, but also convinces international buyers. If a quality is there, the industry as a whole is considered reliable in long run.”

“One of our major problems is delayed payment which seriously hurts the cash flow, thereby hurting our capacity to procure the raw material; the availability of raw material is not an issue by itself. We can see a number of litigations on the issue. We need to do something for bringing in secure payments terms which would benefit the whole industry,” said Mr. Gupta.

“The rate of interest on capital is unreasonably high. Something needs to be done on that front as our industry is capital intensive; and to produce volumes, large CAPEX is needed. Whatever money is needed as working capital or fixed capital has to be invested by the industry and a large interest has to be paid. Large outgo on account of interest may be easily found in our balance sheets. Moreover, we stiff competition on price front from cheaper imports from countries where interest rate is very low as compared to India,” expressed Mr. Gupta.

On Right Trajectory

“I think we are coming out of the darkness or the mess the whole country was in,” said Mr. Vijay Karia, CMD, Ravin Group, “I never felt as excited about the future as I feel today because India is on the right trajectory of growth. And, with lots of initiatives by the Govt. viz. Make in India, Digital India, Smart Cities, restructuring of discoms, all of us have very good reasons to feel excited, feel motivated about the future.

“Coming to Industry, I think there are four Ps that this industry requires. The First P is ‘protection’. We require protection. When we talk of protection, it’s not just the protection in the form of safeguard duties against imports, but it should also encompass the local protection of MSMEs in the form of separate set of taxation laws in order to let even the smallest companies to survive and move forward. Most of the wire and cable industry fall in within MSME segment. Same set of taxation laws are applicable for large as well as small industries. For smaller industries to survive, there must be a separate set of tax regulations.

“The second P is prequalification, which is prequalification for imports and is very essential. There is a BIS license which is applicable to manufacturers outside the country. The BIS license is given on the basis of mere test certificates without ever visiting those plants; or if plant is visited once, there is rarely any follow up visits. So, the local units and these foreign units are considered virtually at par. I think the prequalification criteria should be made more stringent for imports to happen in India.

“The third P is professionalism. Honestly, being part of this industry for long, I feel that we have attained a lot of professionalism, but we have a long way to go. This professionalism also includes skill development for all sets of people; especially the wire and cable industry requires professionalism and skill development in marketing.

“The fourth P is penetration. Again, I say that the Govt. has opened up with such schemes which are sure to vitalize that power sector. The Govt. is talking of distribution reforms, and it is going to mean that we as an industry have to penetrate down to the rural areas where today none of us is concentrating to try and grab the market there.

Talking on the huge interest rate on capital, Mr. Karia suggested a simple formula for interest subvention which will hugely benefit the industry if taken into consideration by the Govt. He explained, “If the government wants to attract an investment of say 1 lac crore into MSMEs, then they should consider the simple scheme I have to propose. At 60:40 debt equity ratio, bank would have to lend 60,000 crores to the MSME sector. Presuming that the bank is lending this money currently at 12% p.a., government should lend this money to the MSMEs (for setting up of new projects only) at 1% p.a. for 5 years. This lending can be taken out of the CRR of the banks, and if RBI lends this money to the banks at repo rate of 6%, then government would have to do subvention of interest costs of 5% only, which would mean Rs. 3,000 crores p.a. X 5 = 15,000 crores for 5 years. Thus with subvention of only 3,000 crores in the 1st year, the government can get Rs. 1 lac crore investment into the MSME sector which would generate a huge amount of employment as well as give real impetus to the growth of the country.”

“For implementing discom reforms, the Govt. would have to bring in large CAPEX. But, in order to supply the underground cables, we need to make ourselves more efficient because the Govt.’s focus would be to get the products at the cheapest possible prices. Because the Govt. is clear that it’s not going to protect the industry for its inefficiency; it may protect the industry from imports as far as it goes to creating a level playing field.

“New private investments in India have slowed down across at least 22 sectors as per CMI data. The offset for this is the Govt.’s spending. So, today, the concrete steps we are seeing is because the Govt. is spending a lot more on infra and that has been sustaining factor for our industry.

“GST is very-very essential today for the industry as a whole. So, whatever way possible, we need to influence the Govt. to try and implement GST at the earliest. I am sure that we all put in our individual as well as collective efforts, we can do that. Once the laws across the states are simplifies and a uniform taxation regime is instilled, we would be able to see a better growth.”

Opportunities Galore in Telecom

Mr. Sandeep Aggarwal, MD, Paramount Communications Ltd. sounded very positive at the prospects of emerging opportunities in telecommunication market amidst myriads of government’s projects and spending. “I believe that country as a whole requires both blood vessels and nerves. Blood vessels carry the energy to each organ of the body and they are power cables. But, the body needs nerves also to work efficiently, and the optical fiber cable network today serves the purpose of a nervous system.

“The nervous system today is weak; compared to the world India is dizitizing very-very slowly. The speeds of transmission are quite low and we call a 520 kbps connection broadband; whereas out in the world probably 10 times that speed is considered normal for common connections. However, with BharatNet program of the Govt. of India, and Rs. 80,000 Cr of investment in the project in the next 3-4 years, India would seem to transform from a backward country, with a very bad quality nervous system, to a country having state-of-the-art nervous system.”

Adding to the above, Mr. Aggarwal went on to say that this investment is going to give a fillip to entire economy, not only the telecom sector. “The capability of India will grow and it will add at least 1 percent to the overall GDP each year. Because, if the data is available, even the remotest part of the country will attract investments. Moreover, if we see our GDP at USD 1.4-1.5 trillion and the gross capital formation is about Rs. 3.2 lakh crores (about USD 500 bn), cables constitute about 1-3 percent of the total capital formation. So, as the growth rate goes up, the demand of wires and cables is bound to grow hugely. Therefore, the telecom growth will yield dividends for other industries as well, especially the wire and cable industry,” said Mr. Aggarwal.

He said, “For quite some time, the capacity build has been in excess of the actual demand growth resulting in very low value addition to the companies. Indian companies are probably getting the least margins on the raw material and we are forced to do that at comparatively lower prices compared to our global competitors just because there is excess capacity in the Indian industries itself.

“BharatNet project is going to connect 562 districts, 6000 block headquarters, and 2.5 lakh gram panchayats with optical fiber network with 100mbps-2.5gbps at every point of connection. This will give boost to cell phone and other intelligent electronic devices. Moreover, most of the industries today work through ERPs and hence they need to be connected across plants. The service sector will also gain hugely from the availability of good network all across the country. And, all this won’t be possible without an optical fiber backbone.

On the subject of govt. spending and protection, Mr. Aggarwal said, “The govt. investment should continue to spur the demand growth. For GDP growth to take place, substantial investment should be infused in the economy consistently including the private investments. But, for that to happen, interest rate should be reasonable making sure that funds remain available for investments.

“The greatest protection we need is obviously from inverted duty structure. This has been often observed that whenever the govt. comes out with a big infrastructure project, it wants to ensure the flow of material from outside at practically zero duty. However, this in long run hurts the indigenous industry. Therefore, whenever the govt. works on the blueprint of contracts, they must ensure that benefits flow to local industries too.”

Bigger Opportunities to Grab

Mr. Abhishek Gupta, Director, Gupta Power Infrastructure Ltd also sounded elated at the prospects India is set to have under the government’s new projects and programs. “Indian industry has the potential to come up big on the international stage with the growth opportunities that have been presented to us with Make in India, Smart Cities, revamping of discoms, etc. If we are prepared enough to embrace the opportunities and convert it to our end, we are poised to make it big,” said he.

“What I mean by being prepared is that Industry must, first of all, come together and act as an organized whole. Brand-building is another front where the collective endeavor of the industry is much sought after. Both the organization and brand-building of the industry is possible only when the industry cautiously weighs the priorities against temporary and personal differences on issues like prices and protection to help the industry grow as whole whose benefits shall be reaped by all.

“I see huge opportunities waiting for the Indian wire and cable industry linked to Indian power sector. The electricity demand in India is sustained and driven by the sustained economic growth. The Government’s target of ‘Power For All’ has accelerated capacity addition in the country. At the same time, the competitive intensity is increasing at both the market and supply sides (fuel, logistics, finances, and manpower).

“The 12th Five-Year Plan estimates total domestic energy production to reach 669.6 million tonnes of oil equivalent (MTOE) by 2016–17 and 844 MTOE by 2021–22. By 2030–35, energy demand in India is projected to be the highest among all countries according to the 2014 energy outlook report by British oil giant, BP.

On the upsurge of renewable energy output and increasing commitments of stakeholders to produce more and cleaner energy have created another sphere of lasting opening for the wire and cable industry globally, said Mr. Gupta. He added, “India’s wind energy market is expected to attract investments totalling Rs 1,00,000 crore (USD 15.7 billion) by 2020, and wind power capacity is estimated to almost double by 2020 from over 23,000 MW in June 2015, with an addition of about 4,000 MW per annum in the next five years. All this is surely going to give unprecedented boost to the demand of wires and cables.

“Around 293 global and domestic companies have committed to generate 266 GW of solar, wind, mini-hydel and biomass-based power in India over the next 5–10 years. The initiative would entail an investment of about USD 310–350 billion. Between April 2000 and September 2015, the industry attracted USD 9.97 billion in Foreign Direct Investment (FDI).”

Cooptition: The New Mantra

Mr. R. Ramakrishnan, Vice Chairman, Joint Managing Director & Group CEO, Polycab Group eloquently expounded the need to move away from unhealthy and pernicious competition among companies hurting the whole industry. “I think the world is increasingly moving towards a situation where it is not about competition any longer, it’s rather about cooptition – a scenario where business rivals or competitors continue to compete in some areas, but cooperate in others. Cooptition is where companies work together, cooperate together to create value, or figure out how we can create value together and get a higher share of that value creation,” he said.

Mr. Ramakrishnan asked some insightful questions from the industry, whose answers would sure enable the industry to find a stable and promising future. Though, he himself never seemed short of coming up with some pragmatic answers to those questions. On the question of responsible leadership, he remarked, “I think any industry for it to flourish, responsible leadership is extremely important. Very often, whenever we have necessity of showing our quarterly results, we resort to some steps which are not value creative, but value destructive, only to show that we are right on the path of aggressive growth. This is not the right leadership.”

Whether industry collectively is doing enough to improve consumption and spur demand, Mr. Mr. Ramakrishnan said, “How can the industry work together in making sure that we work towards industry’s profitability? We all know that revenue is vanity; profit is sanity; and cash is reality. To be frank, if we would analyze the balance sheet of our industry and to assess how much cash we are really generating or what is predictability in terms of collections, we won’t’ find great stories to tell.

“All said and done, India is a great consumption story. And, for a consumption story to flourish, infrastructure has to flourish, buildings have to come up, power has to be available to more and more people, etc. Frankly speaking, we are a good industry. But, are we doing enough to expand consumption?”

Talking on delayed payment and credit related issues, he said, “Credit is a significant issue. We often come across infrastructure companies, EPC contractors, big engineering houses, etc. delaying payments for an unreasonable time period. It is quite often that we as an industry are used to fund their balance sheets. The wire and cable industry collectively needs to work on the issue.”

“Improving industry profitability should be an all time objective for the companies working in this industry. If we keep looking on our individual balance sheets, our specific market targets, the industry will not grow as a whole. I think we need to collectively work for the industry to flourish. We can refer to the reasonable cooperation that exists in FMCG industry, CII, Indian Fan Association, etc. I somehow think that there is a need for us, as an industry, to look at issues that bother industry and take steps,” said Mr. Ramakrishnan. “Unless we create the right ecosystem by which we improve application practices, improve usage practices, improve specification practices, we won’t be able to achieve the profitability for the industry.”

He added, “I think innovation, energy conservation, and environment protection are three neutral areas where we, despite being competitor, can come together and create value together in terms of best practices.”

Before concluding, Mr. Ramakrishnan had a word of advice for Wire & Cable India magazine and the organizer of the show to instill a system in place for the recognition of important and seminal work being done for the furtherance of interest of the wire and cable industry. “A small advice to Wire & cable India magazine, our host today – we need to celebrate the success within the industry. I would urge very strongly that we have a forum like this (Cable & Wire Fair), this is a great platform for recognizing outstanding contribution to the industry. Moreover, I think we need to recognize industry leaders by giving away certain awards of excellence for their vital contributions to the industry in areas like individual R & D, environment protection for reducing environmental footprints, excellent managerial practices, etc.,” he said.

Falling in Line with Global Technological Excellence…

The 2nd CEO Panel Discussion at CWF 2015 on December 3, comprising noted names such as Mr. VK Bajaj, COO, Uniflex Cables Ltd; Mr. Avinash Ladha, Director, TDT Copper Ltd; and Ms. Nivedita Pandya, Director, Diamond Power Infrastructure Ltd, shed light on some persisting issues and answered many doubts about whether India is really poised to confer growth boons on its industries in the form of robust demand growth, and about what needed to be done in order to make the Indian wire and cable industry withstand any challenge whatsoever. The discussion was moderated by Mr. Jasvinder singh, Managing Director, Supermac Industries (India) Limited.

In Sync with Global Practices

Speaking on whether ‘Make in India’ would be able to reinvigorate the India industries across sectors, Mr. V. K. Bajaj, COO, Uniflex Cables Ltd said, “The word ‘Make in India’ has become popular these days, though we have been making in India all this while. For ‘Make in India’ to succeed, the industries have to adapt to international technology, practices and methods in order to be more competitive. Because you don’t make in India only to sell in India, but the idea is that after making in India, you should be able to export it to international market.”

Mr. Bajaj further clarified that we need not worry the competition from international players in the wake of “Make in India” allowing foreign investments. He said, “International players, in their countries, have already reached a level of development. So, the real demand is not as much their as would be needed to justify their existence. As a result, they are moving to developing markets. With China having reached to a certain level of development, it’s India which is offering them a fertile ground of growth with its vast population and power needs. International players would certainly wish to invest in Indian market.

“But, on their own, it’s very difficult for them to come, set the shop, and start selling. They would have to forge alliances, enter into collaborations, and seek cooperation with Indian partners. I think, if they come, technology and international practices will also come with them increasing overall productivity. It’s good and the Indian industry should not feel threatened as it’s very-very mature to fight off any competition.”

On how ready the Indian companies and infrastructure are to better the challenge, Mr. Bajaj said, “In India, if we look at cable capacity, for example, because of the government hypes over so many years, people have already increased their capacity to the extent of it becoming over-capacity. So, I don’t think that within the industry infrastructure is an issue. I think the cable machinery manufacturers, or the cable compound manufacturers are linked to cable industry, which in turn is linked to overall economic growth, which is of course looking on its positive side. It is good for everybody actually.

“However, to be able to reap the fruits of this prospective economic growth, we have to bring in the international best practices, especially in terms of technology and standards. In India, people are happy using XLPE cables having been moved from PVC and still think it’s ultimate. Really speaking, this 90 degree XLPE is little underrated for our kind of country whereas the Europe or USA is using 105 degree XLPE. There is not much difference in the cost, yet we can have substantially increased conductivity. With three percent cost increase, we may avail 40-50 percent increase in the current carrying capacity with 105 degree XLPE. So, BIS and the Indian cable industry should think in this direction.”

On the question of whether the Indian cable industry has of late become more organized, he answered, “Earlier the ratio of cable makers falling in unorganized sector was very-very high, and there were only few players of large size. However, over a period of time, the ratio has shifted towards organized side and that’s mainly because of consumer preference. Overall perception of quality, affordability, and brand are now factors in the minds of customers while buying cables. So, according to me, this movement towards industry getting more organized is primarily owing to customer preference. Though I can’t rule out other factors, such as delayed payments and prolonged credit forced smaller player out of business and players with deep pockets and adherence to quality survived in long run. The organized sectors will be stronger and bigger in days to come.”

On the demand of OFC and quality bandwidth, Mr. Bajaj said, “India is a populous country, and as such the demand for internet and quality bandwidth is immense. Though the number of internet users has increased drastically over past few years, the quality of bandwidth is still wanting.

“The Govt. is surely moving towards that with programs like Digital India and BharatNet where it was envisaged that by March 2015 400,000 kms of OFC was to be procured and installed. As a result the capacity of the industry was increased. Finally, the Govt. placed an order of only 200,000 kms which was duly delivered by the industry. Now, there is no further order as half the inventory is lying unused and uninstalled. So, it’s only the supply of OFC on part of the industry is responsible for making the program a success, but speedy installation and completion of project as per deadline is also necessary. Once these 400,000 kms of OFC is laid, the quality of bandwidth will increase substantially.

On the renewable energy segment, he remarked, “The pressure on climate is increasing and the concept of renewable energy is getting more and more viable as a result. Moreover, the gestation period to set up a power generation capacity in the renewable is much lesser that of in the conventional energy segment. So, of late there has been a lot of thrust given to this sector. Two express reasons for advocating renewable energy are the govt.’s aim of mitigating climate change and fulfill its power generation target with the help of renewable energy. In coming days, this is also going to contribute in the demand growth for cables and wires.”

Copper Quality: Behind None

Mr. Avinash Ladha, Director, TDT Copper Ltd, while speaking on the quality of copper and metallurgical practices, said, “As far as quality and technology with respect to copper is concerned, India is behind none in the world. However, as we are largely dependent on the import for raw material as the copper is negligibly mined in India, the copper commodity making companies should be careful with the choice of raw material.

“In the matters of quality, we are not only in sync with the global standards, but we are exporting to a number of countries where quality is the first benchmark. However, sometimes it’s the customer industry which prefers to downgrade the quality as per their comfort. When we introduced a product called oxygen-free-copper, which is 2 percent better conductor, the industry rather preferred to downgrade the usage and kept using the old copper of 101 percent.

Emphasizing the need to upgrade the usage, design and increase the current carrying capacity of cable, Mr. Ladha said, “I also agree with the opinion that if we increase the temperature, the current carrying capacity would increase. We would also be saving on copper side thereby decreasing the overall dimension of the cable. That’s what has happened in the motor and transformer industry where as we increase the insulation temperature from 105 degree to 200 degree, the size of motor or transformer decreases – possibly because of temperature. The industry must think on these lines.

“Moreover, as far as cables are concerned, we have to be in sync with international standards on design front. Since we are hardly behind anybody in terms of our IT capabilities, design will improve surely as time goes by.”

Smart Cities and other infrastructural Initiatives of the Govt. are to unleash a plethora of opportunities for industries across spectrum, including the wire and cable industry, opined Mr. Ladha. He said, “As far as building Smart Cities and revamping country’s infrastructure, I am optimistic of positive results in long terms. The result might not be instantly visible, but any idea or plan takes time to firm its roots and bear results. So, we have to start planning first which we have done in conceiving the Smart Cities and I’m sure these will turn into reality .And, considering the success of this plan, the multiplied infrastructure requirements will translate into huge demand growth for the wire and cable industry, and other such industries.”

Begin with an Idea

Ms. Nivedita Pandya, Director, Diamond Power Infrastructure Ltd, on the growth of the industry, said, “We know that India is a power deficit country with the lowest per capita consumption of only 940 KW. The wire and cable industry is probably the weakest and last link in the value-chain. The progress of the nation, and especially the wire and cable industry, is essentially linked to the growth of power sector viz. generation and transmission sectors.

On the question of whether the Indian wire and cable industry is growing at CAGR of 16-18 percent, Ms. Pandya said, “Not, exactly. But, yes, we are very close. This kind of growth will be continued for years to come as there is increasing emphasis on increasing the power generation substantially in successive five year plans as the demand for power is tremendous in a populous country such as India. The revamping of discoms and improving the transmission and distribution infrastructure would also result in huge growth demand for wires and cables. On these accounts, the growth is visible, yet it also depends on other factors like challenges and market trends.

On whether the Govt.’s initiatives will work in real, she said, “Idea is central to any project we undertake for completion in future. We must first begin to think in a direction, and then comes planning, execution, and completion. It may take time, but this is the direction, one has to tread in order to develop and progress. The programs initiated by the Govt. of India may look like a paper work at first, but this is a also a step in the process. We first strive, then only we get what we aspire for. Smart Cities, Make in India, Digital India, and other infrastructure projects are efforts in cogent direction, only to be fulfilled by our hard work, strategy, and dedication.

“For example, some years ago, we were not even contemplating on making a wire beyond 66 KV, or 132 KV; we thought we are not capable. But, today, we are manufacturing all sorts of HV, EHV cables in India – only because we ideated, thought, and tried. We, at Diamond Power Infrastructure Ltd, succeeded in making 400 KV cable indigenously, first in India, without any outside technical help.”

Indian Steel Wire Industry Recognition of Tremendous Potential

Call for urgent government attention, easier import norms, accessibility to cheaper raw material, and technology infusion were some of the outcomes at the steel wire panel discussion.

The 3rd Panel Discussion at CWF 2015 on December 4 targeted the Indian steel wire sector, challenges, market trends, and growth outlook. The panel comprised Mr. Dilip Dev, Vice-Chairman, SWMAI & CMD, H. D. Wires Pvt. Ltd., Indore; Mr. Roopak Karnik, MD, Bekaert India Ltd., Pune; Mr. Dheeraj Dev, Director, H.D. Wires Pvt. Ltd., Indore; and the discussion was moderated by Mr. Nirmal Singh, Director, Assomac Machines Ltd.

The discussion touched upon various issues impeding the growth of the industry in a manner as would be expected of it. Amidst immense growth opportunities by way of expanding construction, infrastructure, telecom and manufacturing industries and where steel production has reached an all time high, there is no reason as to why the Indian steel wire industry could not match the growth of other industries, concurred all the panelists. Some of the questions as how the wire industry is shaping today; how the future looks; and the direction in which the industry should be moving were deliberated during the session.

Need of More Recognition

Talking on the status of the steel wire industry, Mr. Roopak Karnik, MD, Bekaert India Ltd., said, “The steel wire industry does not attract a lot of people. If we see the sort of norms the Govt. has promulgated for this industry, it’s hardly unclear that this is a sector not very well recognized. Although it’s an important industry which touches lives across spectrum from agriculture and automotive to power and as such if we can bring technology aspect into this industry, I’m sure this industry would grow as per the aspirations put forwarded by ‘Make in India’.

“We need to see what wires made in India mean to industry and what the model should be for the industry going ahead in order to make its product in sync with the latest needs and desired technological standards.”

The most of the Indian steel wire sector is still very less organized and it’s very hard to assess the true capacity of the industry, remarked Mr. Karnik. He said, “However, it’s estimated that capacity hovers around 2-2.5 million tonnes now, and would surpass 3 million mark in near future. Today, the industry is volume driven, so it is going in its own spiral financially and struggling as a sector. Here again, I would emphasize that if the industry has to grow towards more capacity and come out of this spiral, technology will play an important role.

“For example, 30 percent of car is made up of wire in different forms – be it springs, suspensions, steel cable, etc. We need to work across this whole chain and see how we can bring added value. We can, for instance, reduce the weight of wire components in the automobile by using better grades of steel and alloys which will also help in reducing the carbon footprints. These things are happening in the western world and we are relatively insulated from such developments.”

Speaking on huge investments coming in power sector, he said, “Rs. 3 trillion is going to be investment in power the transmission sector in the next five years as per the Govt. expectations. With the new technologies, the Govt. aspires now to create an ambitious grid programme which will meet the country’s demand. This is a huge opportunity for all us. The question is whether we are looking at these investments which are fundamentally going to be the key drivers for us in years to come. To tap this opportunity, we need to ensure whether we are using the latest technology, or will continue with the technologies which are decades old.

“We should also collectively work with the Govt. to ensure to ensure that we are adopting what is relevant in developed world and that the Govt. allows us to bring these into India because this will actually shape the future not only of our industry, but also of the power transmission sector in coming 50 years.”

Mr. Karnik also underlined that adoption of latest technological know-how will not only result in giving quality products to domestic requirements, but also spur the export of steel wires internationally. “Just to throw some figures, out of our 2 million tonnes of production, we just export 30,000 tonnes of steel wires and that too only to four-five countries in the middle east. Only 4000 tonnes which is produced in India are exported to advanced countries. So, there is clear indication for us to move towards world-class technology to be able to not only service the Indian market, but also the international market.”

“I would also call upon the Govt. to relook on its policy on duty structure which is not fundamentally driven at importing the capital goods for export purposes. It should also need to shed a fresh look for new technology to be brought in the country by giving certain leverages to machine manufacturers,” concluded Mr. Karnik.

Call for Easy Import Norms

Mr. Dheeraj Dev, Director, H.D. Wires Pvt. Ltd. was also supportive of the view that the steel wire industry is not as well-recognized as it should have been. “I would share a small experience we had in the steel ministry about how ignored the steel wire industry is. They always thought that the steel wire industry was all about just wire rods, HR plates, CR Plates, sheets, etc. What the steel wire is, nobody seems to know. I therefore feel right in saying that our industry is a much ignored kind of industry with very less government support,” he said.

He added, “There are financial packages for industries which have Rs. 50,000 Cr – Rs. 60,000 Cr exposure. But, if you talk about industry of our size, we get even bank loans at 12-18 percent, much less the financial packages. Our counterparts in other countries get the bank loan at just 2-6 percent. So, our finance cost is too high and getting technology from abroad is too expensive. For sustaining in the industry, quality is a fundamental requirement and that can’t be achieved without technology.”

Speaking on improving steel consumption, he said, “Per capita steel consumption in India is very low – just 1/10th of the average global consumption. This has to be improved if our industry has to survive in long run. This can happen if govt. spends huge CAPEX in the economy, especially in power sector and infrastructure.”

“Issues at the level of mills must also be deliberated upon. Plant level efficiency is lesser in India and the work culture a bit slack. These have to be dealt with for if we wish to reduce our input cost and increase the productivity at the same time,” he said.

Speaking on easy import norms, Mr. Dev said, “The Govt. should do away with entry level barriers, and our industry must not be forced to choose from only the domestic players like Tata, Jindal, etc. I’m not asking for inverted duty structure, but only rational entry barriers allowing us to import whatever is essential.

“I don’t fear competing with China. Let it come and sell its galvanized wire in India at 10 percent duty with which I don’t have any issue until I’m also allowed to have my wire rods at 10 percent. However, this is not fair to stop us from importing our wire rods and expect us to compete with foreign companies which are getting their raw material 20 percent cheaper than us.

“There is huge demand-supply gap in India in the steel wire sector. How shall be able to bridge the gap given the Govt.’s imposition of various kind of tariff barriers such as safeguard duty and normal import duty, and non-tariff barriers such as Quality Control Order, etc.? There must be a condition tipped with easier import norms for letting our industry chose what’s best for it.

“In last 6 months, there have been huge imports of steel wire in India. But, I don’t remember our association going to ministry asking them to put a safeguard duty on steel wire. On the contrary, as an association, we had a meeting on why we are so incompetent as to allow the import of almost 1 million tonnes of steel wire from China and why we are not in a position to fulfill the demands in our country.”

Improving Consumption

Mr. Dilip Dev, Vice-Chairman, SWMAI & CMD, H. D. Wires Pvt. Ltd. said, “The steel wire industry today is versatile enough to meet the requirements of numerous consumer sectors. However, per capital steel consumption is quite low in our country which has to be improved for boosting the demand. The reason of low consumption may be because steel is expensive and there is plastic as its substitute. So when the prices have come down, it will surely improve the consumption.

“Main consumption of steel is in infrastructure and road projects, and steel is not being consumed in these activities as much as was expected. Electrical utilities, cable armoring, etc. are also not able to boost the consumption. Govt.’s projects are also not coming up in a manner to increase the consumption to noticeable level.”

He also indicated that difficult import conditions put by the Govt. is also hindering the growth of the steel wire sector in India. He said, “The Govt. should make such import norms that allows us to buy the raw material at right price. Moreover, the Govt. should control main producers like Tata, SAIL, Jindal, etc. in order to keep prices competitive and there must be price parity between their domestic sale and export. The Steel Wire Manufacturers Association of India (SWMAI) has urged the Centre for full reduction in customs duty on wire rods.”

About Quality Control Order, he said, “The Steel and Steel Products’ (Quality Control) Order, 2015 will lead to cost of steel inputs soar to an unprecedented level thereby making the products across micro, small and medium enterprises (MSMEs) non-competitive. We urge the Govt. to revisit this non-tariff barrier in the light of our industry’s needs and its sustainability in long term.”

Exhibitors’ Speak…

The Cable and Wire Fair 2016 organized by WIRE AND CABLE INDIA was a well managed show with good turnout from most parts of the country. We received very good footfalls on all days of the exhibition including Top Management and Middle Management of various Cable Manufacturers across India. The CEO Conclave was a good addition to the show and helped in promoting the show further. We look forward to be a part of this show in future as well. In future we expect international clients to visit the show as well which can make it a global event.

We received very encouraging feedback regarding our Displayed machines, Double Twist Buncher and Dual Auto Take-up for RBD. We were able to finalize good value of orders within 1 month of the exhibition.

— Mr. Varun Kapoor, Director,

Sarvasv Machinery and Equipments Pvt Ltd.

_________________________________________________________________________________

Overall a good Show, generated inquiries, and executed 2 orders. Next time, I am sure, it will be a big show with lot of participants.

— Mr. Pawan Tyagi, Director,

Associated Machinery Corporation Ltd.

_________________________________________________________________________________

Satisfied overall with the participation in the show. Most likely, we will participate in the next show too.

—Mr. Harcharan Singh,

GM – Marketing, Aarti Steels Ltd.

_________________________________________________________________________________

Overall satisfied with the show. Visitors’ footfall was a surprise in terms of numbers and representations.

— Assomac Machines Ltd.

_________________________________________________________________________________

We will give A+ (Very good) rating for overall arrangement, facility and support. We were quite impressed with the conference running conjointly; thoroughly enjoyed the technical sessions.

— Jayshree Jadhav,

Manager-Marketing, Lifeline Technologies

_________________________________________________________________________________

The show stands successful for us in terms of total number of visitors visited our booth. We made 40 new contacts during the show. Will surely participate next year.

— BLS Poymers Ltd.

_________________________________________________________________________________

Exceptionally satisfied with the participation in the show. Certainly will come next year to participate.

— Mr. Carmelo Maria Brocato, Vice President of the

Board, Commercial Director, Continuus-Properzi S.p.A.

_________________________________________________________________________________

Extremely satisfied with the Participation in the show. Impressed with the Artwork on the Stand walls. Possibly will participate next year.

— Mr. Kevin Bennett,

Sales Director, BWE Ltd.

_________________________________________________________________________________

We were satisfied with the show, Visitors and the services provided. Adjoining conference was a great attraction.

— Carl Bechem Lubricants India Pvt Ltd.

_________________________________________________________________________________

Received extended cooporation from the organizer. Quality visitors were present. Look forward to have more companies on wire side.

— Mr. Rakesh Malhotra,

Bansal Wire Ltd.

_________________________________________________________________________________

We were satisfied with the show, visitors and the services provided. We are looking forward to exhibiting in the next one slated in 2017.

—FARBWERKE HERKULA® SA/AG

_________________________________________________________________________________

We launched VPro- Star of attraction in the show. 5 machines of Laser marking were sold out and received few orders too. Show was fabulous. Quality audience was there and most importantly all important industry people attended the show which serves the purpose of exhibiting.

— Mr. Mohan Pandit, Director, LMI Ltd.

_________________________________________________________________________________

We were satisfied with the overall arrangements and visitor turnaround. Keep up the good work.

— Mr. AS Baghel, Director,

Cabletech Machines Ltd.