Businesses, Ideas, and Leaders together to discuss the future of the sector

Cable & Wire Fair 2015 is all set to become the growth partner of the buoyant Indian wire and cable industry. The Indian wire and cable industry, 40 percent of the electrical industries, is growing at CAGR of 15 percent consequent to the growth in power and infrastructure segments.

Automotive, telecommunication and construction industries, three most important customer segments, are growing appreciably with annual growth of 25 percent in past few years signifying extremely busy days for the wire and cable industry. USD 1 Trillion financing opportunities in infrastructure for global investors over the next five years, Indian automobile expected to touch USD 145 billion by 2016, and the Indian real estate market rising up to USD 180 billion by 2020 are some invigorating indicators.

The Govt.’s commitment to provide 24×7 affordable and quality power to the nation is spurring unprecedented growth of power generation and transmission segments in the country. Overall generation in the country from 967.150 BU (2013-14) to 1048.673 BU (2014-15) with overall growth rate of 8.43 percent, USD 50 billion investment supported by the Govt.’s 18 billion in the transmission sector, the telecommunications market being the third largest and the fastest growing, etc. are sure indicators for the growth of wire and cable industry.

India has a lot of potential in the mining, power, oil and gas, metro railways, cement industry, steel industry and other sectors. Different kinds of cables like extra high voltage cables, elastomer cables, etc., are now being used for special applications such as mining/oil sector, shipbuilding/crane cables/elevator cables, cables for solar power plants, to harness power for new generation motor vehicles, windmill solutions, security systems and other types of data cables.

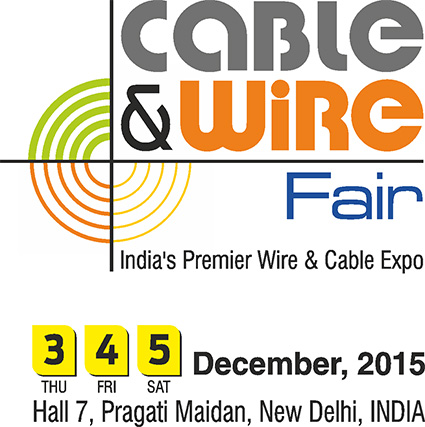

Cable & Wire Fair 2015, 3-5 December, Pragati Maidan, India is a synergizing effort to bring together people, leaders, technology, ideas, and products & services of the wire and cable industry. The show is designed to attract all manufacturers, suppliers, technologists, and end-users to share their repertoire with others in the industry and is equally enriching for visitors. The show ensures great visitor and exhibitor turnout from all across India including the Middle East and SAARC nations. Conference on crucial themes, brainstorming by leaders in CEO Conclave, Panel Discussions on related issues, assured large footfall of quality visitors, and more make the show a stand out option for you to participate.

To know more about the show, please visit: https://www.wirecable.in/fair

..PRINCIPAL SPONSOR..

KLJ Group

Started in 1967, KLJ is the largest manufacturer and the market leader in Plasticizers & all type of Polymer Compounds in South Asia. Their ultra modern manufacturing facilities at Silvassa & Bharuch in India and at Rayong in Thailand are equipped with state-of-the-art-technology, producing a wide range of products to meet their Customers’ requirements. KLJ is in an advanced stage of setting up an ultra-modern Chlor-Alkali plant in Qatar; expected to be upstream by 2016.

KLJ is also diversifying into chemistry of Benzyl Alcohol, Benzaldehyde and its derivatives. The project is coming up in Jhagadia, Gujarat and is expected to be commissioned by end of 2015.

Making use of vast Supplier, Distribution and Customer network, the Group has also made strong in-roads into Trading of Petrochemicals, Derivatives & Polymers.

Supermac Industries(India) Ltd.

Supermac Industries, the brainchild of Mr. Harbhajan Singh and Mr. Karamjit Singh, has evolved from a vision to a world leader in high end manufacturing systems and process technologies for the cable industry.

Supermac, due to its pursuit of excellence and innovation, has emerged as a world leader in extrusion lines manufacturing. Its understanding of the growing demand for processing of new materials enables it to come up with the kind of industry solutions that are trusted by the cable industry world over.

Supermac today is best known for advance custom solutions in manufacturing of an assortment of insulating and sheathing machines for the cable industry. It is the only Indian cable machine manufacturer to be awarded the prestigious CE Mark for its range of products – a feat that the company owes to its people, its belief in creating extraordinary solutions and a dynamic approach for the future.

Infra

Supermac’s three technically advanced production units in Manesar and New Delhi power the company’s vision to research, manufacture and deliver high-end extrusion lines for varied cable manufacturers. The three units span an impressive area of 95000 sqft to house a cutting edge production and engineering facility.

Supermac’s infrastructural strength comes from its vision for groundbreaking developments in the field of extrusion. This approach has made it a technological leader and the only Indian company to have in-house automation, panel making and testing facilities.

The manufacturing hub is powered by advanced CNC equipment responsible for manufacturing high-end precision components for extrusion lines. The entire manufacturing process is backed by an integrated ERP delivering managed output and streamlined process flow.

The company follows strict engineering standards for its engineered products. All the products are validated in-house ensuring finest quality that Supermac is known for.

Products

The company is recognized for pioneering work in the extrusion cable machine manufacturing industry. In has already successfully deployed more than 400 lines in India and abroad. The range includes:

- Insulation and Sheathing lines for Power Cables

- Sheathing and jacketing lines for PIJF telephone cables

- Insulation line for control cables, BUILDING WIRES, AUTOMOTIVE WIRES

- Sheathing lines for optical fibre cables

- CCV lines for medium and high voltage cables upto 132 Kv.

- Sioplas line for MV cables upto 33kv

It also manufactures ancillary machinery and components including Extruders upto 175mm screw diameter, pay-off and take up stands up to 4.5 meter height and to load 40 tons weight, Caterpillars, Capstans and cross heads.

Quality

Quality is the lifeline of Supermac. “It’s here for change” philosophy has earned the company the prestigious Gold Award at Quality Summit in New York. The company has also been awarded the CE Mark for its high quality products. All its processes are governed by stringent ISO guidelines and in-house quality control techniques.

Empowered with world-class infra, market intelligence, comprehensive market network and thorough professionalism, Supermac has become unparalleled in providing best-suited manufacturing systems and process technologies for the cable industry.

..CO-SPONSOR..

Assomac Machines Ltd

Assomac has established itself as one of India’s leading names in the field of wire drawing machinery, wire cutting machinery and wire making machinery with the promise of quality products that stay ahead of time. It is an integrated conglomerate of engineering companies engaged in manufacturing all types of equipment and accessories used in making alloy steel, carbon steel, mild steel, stainless steel and other non-ferrous wires. The company works on the solid foundation of the very latest technology and the best equipment. It is supported by a team of highly qualified and well-trained personnel. In a short span of time, Assomac has become one of the leading manufacturers of superior quality machines.

The plant is spread over an area of 45,000 sq. m. with a total covered area of more than 200,000 sq. ft. It has the following capabilities:

- In-house design and development shop having 3D & 2D CAD systems with state-of-the-art software like solid works, Pro-E, Auto CAD– inventor and e-plan.

- R&D workshop with facilities for testing of ferrous and non-ferrous wires and their alloys.

- Complete metallurgical lab with chemical and physical testing facility and inspection centre.

- Fabrication shop with state-of-the-art CNC, plasma/gas profile cutting, CO2 and flux cored argon arc wire welding facilities with other processing equipment.

- Foundry having induction melting, crucible and cupola furnaces with shot blasting facilities for best quality, S. S., M. S., C. I. and non-ferrous castings.

- Machine shop having state-of-the-art CNC, VNC, turner cutter, vertical machining centres lathe machines, boring machines, milling machines, cylindrical grinders, VTL, plano-millers, etc.

- Latest HVOF tungsten carbide spray coating robotic plant from Sulzer Metco (first time in the Indian wire industry) to improve the quality of wire manufacturing.

- FRP/PP section for making online cleaning and fumeless systems.

Sarvasv Group

Founded in 1984, Sarvasv with time has earned the reputation of being the most innovative and out of the box thinkers in the market. They are the technological leaders in cable machinery manufacturing and consultancy in India and have been working towards the goal for complete customer satisfaction ever since the day it started. They have manufacturing units that are equipped with the most sophisticated and modern machinery and equipments, which are complemented by highly qualified and experienced team of professionals who are always striving hard to improve on the already attained success. A dedicated quality assurance team ensures strict guideline adherence from raw material stage to final commissioning of machines. All this has made Sarvasv reach heights that no Company has till date attained. Sarvasv has been exporting their machines to various countries across the globe particularly to UAE, Bangladesh, Nepal, Iran, Africa, Europe and Australia.

Sarvasv has excelled in offering the best after sales service to their clients over a period of 35 years now. This has ensured repetitive orders from clients. At Sarvasv we have always believed in strengthening their relationship with existing clients by offering them the best services at all times. They have always fulfilled their commitments and have hence ensured a very strong reputation for Stability and Service over the years. A dedicated team of field engineers are always ready for any customer queries. These engineers have specially been trained for problem solving and maintenance issues and have rich experience in the wire and cable manufacturing.

Sarvasv archives detailed drawings for each machine manufactured and any change or damage of parts can be easily replaced by the client at the shortest notice. A large number of standard components are maintained in inventory as well to ensure shortest lead time and hence ensure that the downtime for the client is reduced.

KEY PRODUCTS

- High Speed Skip Stranders

- High Speed Double Twist Bunching Machines

- Automatic Dual Spooler for Rod Break Down Machine

- High Speed Rigid Stranding Machines

- Armouring Machines

- Planetary /Back twist Stranders

- Core Laying up Machines

- Drum Twisters

- Takeup and Payoff Units

- Extrusion Lines

..ASSOCIATE SPONSOR..

Swastik Polyvinyls Pvt. Ltd.

Swastik Polyvinyls Pvt. Ltd., hold fast to the ideology of constantly working towards developing new and improved products for their clients. Our firm was incepted in the year 1975 with an aim of providing cost-effective and reliable PVC compound as per the requirement of our customers.

Our dedicated efforts and consistency in providing quality goods have won us the trust and support of a number of clients scattered all across the globe. An ISO 9001:2008 certified company, we are recognized as an eminent Manufacturer and Exporter of PVC Compound (Insulation & Sheathing), PVC Master Batch, PVC FR or FRLS Compound, PVC Lead Free Compound, which are in our in-house laboratory tested for their efficiency and properties. Focus on every formulation stage of compound to comply with requirement of toughness, impact strength and heat resistance, we have strategically set up technologically powered infrastructure to better formulation, storage and packaging of PVC Compound.

We have expertise in formulating PVC Compound and other compounds in bespoke compositions in line with application need of clients. We as a company driven by challenges for meeting the quality excellence, are inclined to making our clients 100% satisfied. We have support from a team of experienced chemical engineers and researchers having in-depth knowledge of market needs and industrial dynamism. We retain customers for lifelong through fine product quality and congenial customer support. We bring good repute for the company by meeting the challenge of price and value, therefore having established long standing business relation with leading companies. Today, we are exporting our products like PVC Compound to almost every corner of the globe. We also import PVC Resin, Plasticizers (DOP, DBP, DINP, DOA, TOTM, etc.), Calcium Carbonate, Stabilizers (TBLS, DBLS, DBLPH, Calcium Zinc, etc.), Chlorinated Paraffin Wax (CPW), etc.

Walson Woodburn

Woodburn Diamond Die (since 1957) is one of the largest wire die producers in the world with 7 manufacturing plants world-wide (USA, Mexico, India – 2, Thailand, Indonesia & Russia). It exports to over 50 countries world-wide, including: Japan, Korea, Malaysia, Germany, France, etc.

Product Range:

- N.D & Mono-Dies -0.020mm to 1.000mm

- P.C.D Dies –0.025mm to 38.000mm

- T.C Dies: 0.200mm to 38.000mm

- Extrusion Dies & Tips

- Enameling Dies

- High Speed Multi-Wire Die Sets (Elongated)

- PCD Stranding & Compacting Dies: 0.500mm to 38.000mm

Quality Control Equipment:

- Die Profiler – Conoptica (Norway)

- Laser Micrometer (USA & Italy)

- Stereo Zoom Microscopes (USA & Japan)

- Wire Elongation Machine (Germany)

The Maillefer Group

Maillefer is the global leader in wire & cable and pipe & tube production technologies. We offer over 50 technologies and the widest services portfolio in the industry to cover nearly 20 applications. From us, you can always get the best technical fit and value – from a single component to a complete factory – to match your lifecycle needs.

To serve our customers fast and accurately, we have five regional sales and service centers in China, Egypt, India, Russia and USA, and a network of 50 agents worldwide. The Mumbai regional sales and service office is supported by ASACO – our loyal agent for 35 years from Hyderabad. Our two global competence centers in Finland and Switzerland provide customers with global know-how and best practices.

Read more about our whole product portfolio at www.maillefer.net and read our latest news at blog.maillefer.net.