Rapid urbanisation worldwide has led to a growing demand for high-quality medium voltage (MV) and low voltage (LV) underground cable systems that provide power to industries and households. Thus, power utilities are continuously working to improve cable system design to deliver long-term reliability.

Cable jacketing is the first line of defence against moisture and chemical or physical abrasion, a shield for the insulation screens and conductors within, and also a protection layer against installation damages. As such, it is critical that a cable’s jacketing material enables the cable to retain its mechanical properties despite physical changes in its environment.

The Risk of Power Cable System Failures

Underground power cable systems are designed for an operational lifetime of 30 to 40 years. To achieve this, the most critical element is monitoring the rate of degradation of the semi-conductive screens and cross-linked polyethylene (XLPE) insulation material.

Thus, to mitigate the risks of cable failure, power utilities should pay close attention to the following areas that can lead to degradation of the semi-conductive screens and XLPE:

- High thermal stresses

- High electrical stresses per mm of insulation material

- Impurities or non-compatibility in the semi conductive screens or XLPE

- Excavation and cable installation work

- Water ingression creating water trees in the XLPE

Raw material selection and correct material handling can control the impurities or non-compatibility of the semi-conductive screens and XLPE. For jacketing materials, the IEC60502-2 identifies designations of power cable jacketing materials in “ST” classes for PVC, PE, and flame retardant uses. ST7 in particular allows the use of PE in jacketing, and Borouge offers Borstar® ME6052 and HE6062 to support this.

Different climates and environments require dedicated specifications, for example, cable installation in buildings and highly populated areas may require flame retardant properties while underground cable systems may require water retardant cable jacketing materials.

High density and medium density polyethylene power cable jacketing materials

1. Moisture barring properties of polyethylene

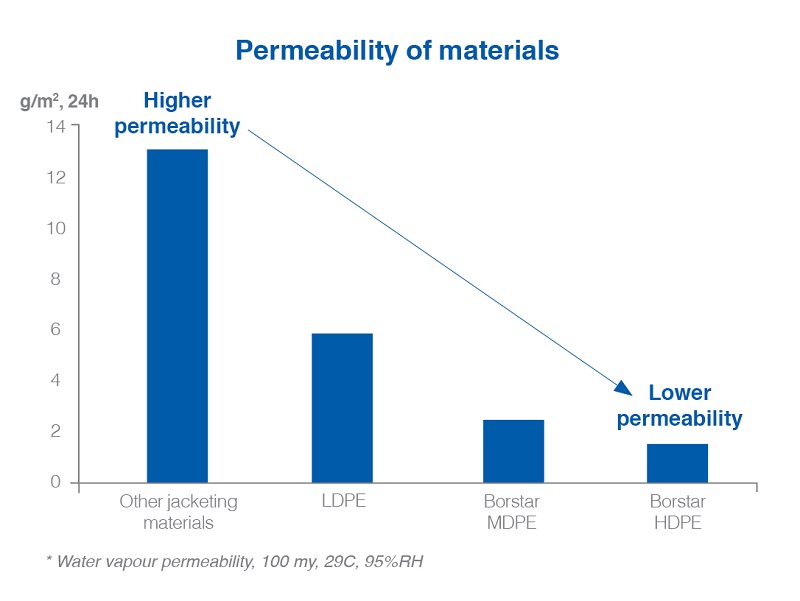

Amongst the different types of polyethylene jacketing materials, high-density polyethylene (HDPE) and medium-density polyethylene (MDPE) are the most well-known ones. For power cable systems it is important that the XLPE and semi-conductive layers have limited exposure to moisture and water. Figure 1 shows that the moisture barring properties of MDPE and HDPE are almost 6 times as effective as other jacketing materials. Hence, MDPE and HDPE will significantly reduce moisture and water to ingress to the core of the power cable system.

According to a research study from H. Orton & R. Hertlin, moisture migration in power cable systems has a large effect on the electrical breakdown strength. Moisture ingression can reduce the electrical breakdown strength by 50% over a period of 10 years.

2. Polyethylene enables lightweight cables

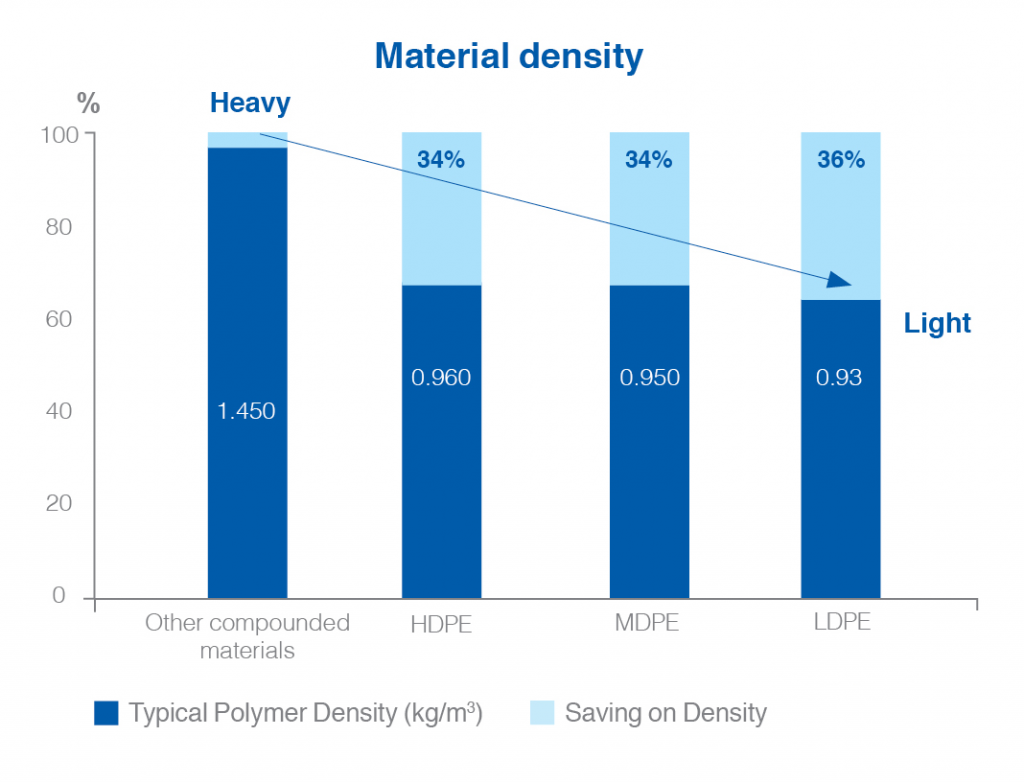

The density of a jacketing material determines the weight of it required to reach a certain jacketing thickness. If the material density is lower, a lower weight is required to reach a certain thickness. Figure 2 shows that compounded solutions can have a high material density while HDPE is lighter.

- Lower consumption of material enables lower costs. Assuming a scenario where the price levels of different jacketing materials are on par, the significantly lower density delivered by HDPE and MDPE can result in 30-40% cost savings

- Less material used makes the cable more energy efficient to transport and easier to install

3. Circularity of polyethylene cable jackets

Improving the way plastics are designed, used, and recycled to extend their lifespan is key to driving a circular economy.

The focus on circularity in the power cable industry is also increasing, with cable producers becoming more conscious on recycling due to environmental constraints. Therefore, cable manufacturers are looking for alternative solutions which enable them to use similar types of polymers which do not require separation and can be used conveniently in recycling. Such methods of re-using PE can thus be a viable option to lower carbon footprint and ensure a sustainable lifecycle of power cables.

Conclusion

It is important to select the right cable jacketing specifications according to its installation environment. Polyethylene jacketing materials are an appropriate choice for underground MV and LV cable applications where no flame retardant requirements are in place.

The lifetime of MV and LV power cable systems can be extended with the excellent moisture barring properties of polyethylene. Furthermore, the lower density of polyethylene can deliver significant savings in material costs and enable lighter cables for ease of transportation and installation.

As a reliable partner to the cable industry, Borouge and Borealis aim to provide outstanding value and create competitive advantages for our customers. We continue to invest in research and development to continuously expand our portfolio of tailored solutions that enable high-quality power supply systems that deliver long-term reliability and cost savings.