At LAPP, we are currently thinking intensively about which data is really needed and, above all, why? The “why” is easy to answer: We want to offer our customers specific products and services which in turn enable them to create better ones themselves. In higher quality, in less time or at a lower cost. That’s why we don’t just collect randomly, but question the exact use case and added value for the customer in all the information we gather. If this cannot be answered, there is no reason for us to collect such data at all.

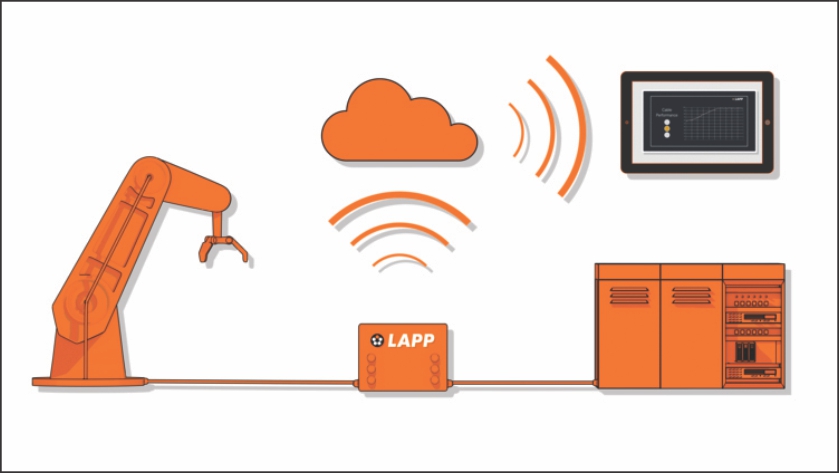

LAPP is running numerous digitization projects at the moment, which also always deal with the correct use of data. In addition to condition monitoring and predictive maintenance, we are also revising our content management system and redesigning our digital product catalogue. We came to the conclusion at an early stage that it is not the quantity of data that is decisive for success, but it is quality – Better Data instead of Big Data. That’s why we don’t just collect randomly, but question the exact use case and added value for the customer in all the information we gather. If this cannot be answered, there is no reason for us to collect such data at all. It is particularly important to us that this is done in compliance with data and privacy regulations. I am a fundamental supporter of the GDPR, as it emphasizes the value of personal data. It is demanding in its implementation, that is true, but it also creates clarity for us providers and gives control back to customers regarding their own data. In accordance with GDPR, we are revising our customer relationship management and cleansing the data records. Sounds like a lot of work, but it contributes to the clarity and accuracy of the information and thus to a higher quality in customer relations.

These figures show what a monumental task we are facing: The LAPP catalogue contains around 40,000 products, from cables by the meter to connectors and tools. For each of these products, we are checking all product features. These are probably an estimated six million individual values. And then we adjust them, add new ones, pull attributes apart, and even discard some of them. By hand. At present, only a small part of this can be automated. We primarily rely on the many years of experience and expertise of our product management and sales departments to accomplish this.

The right interpretation: Knowing what lies behind the data

When we change the attributes, we have to think both about making them readable and usable for humans as before, but also for all kind of systems in the future. Here’s an example: Many of our products are designed for a specific temperature range: for example, a cable with the attribute “-30°C to +120°C”. In the printed catalogue it would also be written in the exact same way and even non- experts would understand the meaning. In the online catalogue, the challenge is somewhat different: A customer may need a cable that can withstand at least +80°C. To do this, he would set a filter such as “>80” for the search. The search software has to understand that this can result in different temperature values for the lower and upper range, and secondly that the upper range is the important one. At the same time, it has to exclude the possibility that an American might not mean ° Fahrenheit. The example demonstrates that it is not simply enough to digitize all information, but that it is also necessary to understand the connections between them. We digitized our analog print catalog years ago, but now it is mainly a matter of adapting our way of thinking and assuming that our customers will primarily use all offers digitally.

This is not only a technical challenge; it takes us even further. We know from the past, for example, that two product managers can weigh the same product feature differently in terms of its significance. For example, is it something special that a specific cable can withstand +120 °C and should, therefore, be emphasized? Or is it just one property among many and therefore of minor importance? This decision still has to be made by a person, because expertise cannot be automated. The meaningful description of a product is an essential part of our value creation and is therefore treated with maximum care. Producing a cable that can withstand 120 °C is something our competitors can do as well. But we at LAPP also manage to explain to the customer why this particular product is exactly the right one for him and his requirements. If it is used in food production, for example, he must clean the cable with hot steam and be able to rely on its resistance despite chemical influences. Imagine what can happen if such a product description is faulty and the purchased product only withstands 80°C. Steam cleaning can cause cracks to emerge, which in turn can lead to a production stop or even personal injury. A catastrophe.

Flexibility and stringency – how to manage the balancing act

The know-how we have about our products, as well as the challenges our customers face, cannot be lost in the digitalization process. Ideally, our descriptions become even more accurate with the help of it. This is where the involvement of a wide range of different departments as well as the brainpower and expertise of many people is required. And because we do not take data governance lightly, we have formed a special committee for this purpose. It discusses and decides which attributes we ultimately introduce. But caution is called for here: If one product attribute changes, this may also be true for thousands of other products and descriptions. But the committee is only the tip of our big change management project for digitization at LAPP. Our managers have a clear responsibility to take people with them and free them from the fear that all they have to do now is knock figures and values in the data quarry. Rather, we have to make it clear which added value the customer receives and which advantages we derive from it.

For us, a key factor is to maintain sufficient flexibility despite all the stringency. Before we started, we talked to other companies that were already a little further along in their projects. In some cases, very rigid rules were imposed on them for the collection and processing of data. Now they complained that they could no longer get out of the corset. We want to avoid this mistake by reconciling stringency and flexibility. To do this, we must ensure that people with their different expertise and skills communicate with each other. This will also help that this project, which is, of course, being pushed at great speed for the first time, is still alive years later.

I have already talked about the what for: We do it all for our customers. But how exactly can they benefit from better data quality in the future? We can imagine, for example, that we make our customers an offer – and perhaps even deliver the product – before they even know they need it. Not every customer wants that, of course. While some already know exactly what they need, others have a high need for advice and decision-making. We want to provide the best possible support for both customer groups, and that can only be achieved with data – better data, in my opinion.

– This article has been written by Mr. Alexander Lapp – Senior Manager Digitalisation & e-Business, LAPP Kabel