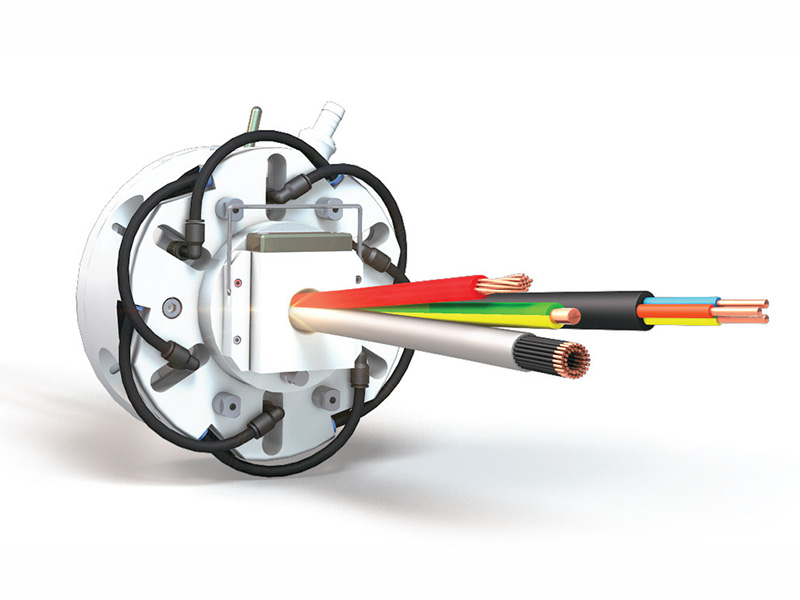

The line of ZUMBACH’s UMAC RZ65 ultrasonic eccentricity and wall thickness scanners for cable insulations, tubes and hoses allow avoiding outrageous maintenance charges. Thanks to the completely new design, the transducers can synchronously be adjusted within seconds to the best possible measuring position. The scanners cover an outside diameter range from up to 65 mm (2.5 in.). They represent a smart and simple solution for fully non-contact, in-line eccentricity and wall thickness measurement.

.

Many advantages and numerous benefits

- Quick centring, thanks to the eccentricity measurement and adjustment from the very first second, regardless of the materials’ temperature

- Completely automatised process monitoring and quality control

- Easy and product change within a few seconds, thanks to a quickly removable segment

- Quick and easy symmetrical positioning of all transducers, centrally adjustable

- Available for 4 and 6 point measurement

- Large measuring range with the same scanner

- No readjustments, no tools, no change of transducers

- Fully non-contact, uncritical centring

- No wear parts

- 100% made of non-corrosive materials for maintenance-free, long-life operation under water

- Important material savings

- Return on investment within a few months

All ultrasonic UMAC systems offer flexible mounting options including inside cooling troughs and spray tanks, or in a separate installation tank provided by Zumbach.

By means of further components, such as proven WALLMASTER data acquisition, processing and display systems, ODAC or MSD diameter and ovality gauges, KW lump and neckdown fault detectors, etc., a UMAC WALLMASTER system can be extended for any case for the highest possible productivity and product quality. These systems provide you with flawless SQC /SPC reports of the final product.