ASSOMAC Group stands as one of India’s premier manufacturers in the wire machinery domain, offering a diverse array of equipment and accessories utilized by various businesses. The company prides itself on its advanced technology, top-tier equipment, and a dedicated workforce backed by a team of highly skilled and trained professionals. In a relatively short period, ASSOMAC has emerged as a key player both in India and internationally, recognized for producing and supplying turnkey wire drawing plants, wire galvanizing lines, and related machinery. In an exclusive interview, Mr. Ashish Tyagi, Managing Director of ASSOMAC Group, discusses the company’s market presence and technological innovations that distinguish them from their competitors, ultimately providing clients with exceptional technological solutions.

Wire & Cable India: Could you share the recent developments within your company?

Ashish Tyagi: For any forward-thinking organization, new developments are part of a continuous journey. Technology is rapidly evolving, and so are the challenges we face. The global wire and cable market is witnessing substantial growth, and ASSOMAC Group is also on an upward trajectory within this sector.

Over the past few years, we’ve invested significantly in advanced machinery to enhance our production capabilities. These state-of-the-art machines have improved the quality of our products and boosted our operational efficiency, allowing us to meet the needs of a growing market. As the wire industry evolves and explores new horizons, we remain dedicated to leading in these advancements.

WCI: Can you elaborate on your market presence and the sales volume distribution between export and domestic markets?

AT: Our operations have made a significant impact in both the domestic and international markets. Demand for wire and related products has surged over time, leading to consistent requests for expansion from our customers.

We actively participate in the Wire & Tube shows in Düsseldorf, which have yielded promising results, expanding our customer base internationally. Year after year, we see increased attendance at our booth. Additionally, engaging with wire professionals and experts has been rewarding, as these interactions help us stay updated on global innovations, enabling us to provide the best technological solutions.

Watch: West Coast Optilinks

WCI: Could you share some significant milestones of your company?

AT: ASSOMAC Group has many first to its name like manufacturing the first continuous OTO type wire drawing machines in the late 60s, manufacturing first inverted drawing machine in India, first indigenously designed and manufactured straight line wire drawing machine, first indigenously designed and manufactured PAD and nitrogen wiping systems for wire galvanizing and many more such developments.

For more than twenty years, we have been continuously honored with Project Export Awards by EEPC of the Government of India. This recognition highlights our dedication to quality and establishes our presence as a significant player in the global market.

WCI: How has your product range evolved over the years? Which products perform the best in the market?

AT: In the engineering goods manufacturing sector, continuous innovation is driven by market demands. Our clients frequently challenge us to design new machines tailored to their specific needs, which has led to an expansion of our product range.

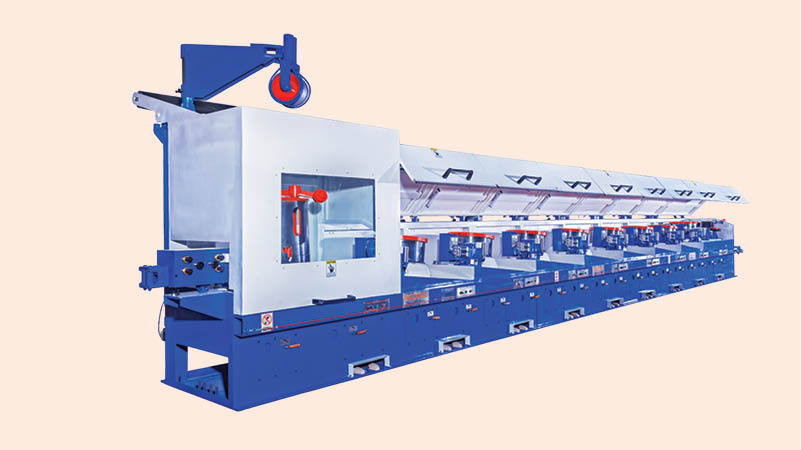

We take pride in our high-quality machinery, which includes Straight Line Machines (SLM), Inverted Vertical Drop Coilers (IVDs), wire ribbing lines, MIG wire lines, wire galvanizing plants, and wire mesh plants. These products are well-regarded in the domestic as well as the international market and are competitive with those from leading manufacturers worldwide. Our commitment to addressing the evolving requirements of our clients is central to our success, prompting us to continually enhance our capabilities and broaden our reach.

WCI: How does the ASSOMAC Group maintain its technological edge in the wire and cable sector?

AT: Our steadfast focus on innovation keeps us at the cutting edge of technological progress. As the global economy approaches a new industrial revolution (IR 4.0), ASSOMAC Group has adeptly harnessed technology to craft an edge for our customers rightfully delivering the best quality and value to them.

The challenges presented by the COVID-19 pandemic imparted invaluable lessons. Our skilled engineers swiftly adapted to digital technologies, allowing for remote plant commissioning and the continuity of operations. We are evolving from traditional machinery to modern solutions that enhance functionality, reliability, and capacity—all while addressing current environmental concerns. Research and Development play a critical role in our continuous growth, establishing the necessary foundation for future innovations.

Also Read: CONDAT group: Making Inroads in Asia with Sustainable Lubricants

WCI: How has automation greatly enhanced ASSOMAC Group’s manufacturing capabilities and infrastructure to strengthen its position in the wire and cable industry?

AT: At ASSOMAC Group over the past three to five years, we have made substantial investments in improving our internal manufacturing capabilities. The implementation of automated systems on our production floor has optimized our processes, resulting in significant time savings and enhanced operational efficiency.

This automation has enabled us to manufacture top-notch components and equipment, which significantly benefits our customers throughout our partnerships. We understand that innovations in manufacturing require sustained effort and dedication to continuous improvement, which we have embedded in our company culture. A key element of our success is our committed team of enthusiastic employees at all levels, whose efforts and dedication propel our mission forward.

WCI: What is your perspective on the current state of the wire and cable industry, and how do you envision its future?

AT: The growth of any nation cannot be fully appreciated without acknowledging the crucial role of the wire and cable industry, which is essential for infrastructure development. The wire and cable industries serve as vital components for national progress. For example, the housing and construction sectors utilize a significant variety of wires and cables.

Presently, the demand in India’s steel sector is experiencing robust growth, approximately 13-14% year-on-year for the financial year 2023-24, with forecasts indicating a continued growth rate of around 10% moving forward. Notably, the housing and construction industries constitute over 50% of the nation’s steel production, which is also seeing a significant growth. Given its essential role within the steel sector, the wire industry is viewed as a key contributor to our nation’s development. As market trends evolve, we believe the future of this industry looks exceptionally bright.