“We see an enormous future for e-beam cables and it is only a matter of time that you’ll see these types of cables being used in almost all the applications.”

Excerpts of the interview with Mr. Manish P Jiwani, Chairman, Anand International:

Product Portfolio and Technical Capabilities

At present, we’re an emerging company in the wire and cable industry. Our main focus is on EBXL wires and cables, which includes – solar cables, high-temperature wires, EBXL PVC cables, and many more.

The Electron Beam Cross-Linked (EBXL) solar cables offer superior performance in extreme environments. The cable can continuously operate at 125 degree C temperature. It has better UV and ozone resistance and exhibits improved weather resistance in adverse conditions. Also, the cables have an improved oil, chemical, and crack resistance and also possess improved mechanical properties at elevated temperature conditions.

Manufacturing and Technical Setup

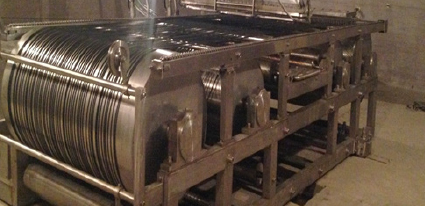

We have a state-of-the-art in-house unit for manufacturing e-beam wires and cables followed up by a testing facility of the complete range of cables. Moreover, we’re still the first and the only company in India that is involved in providing beaming services in the cable industry. We believe that we’ve given small and medium cable manufacturers a push to get into the e-beam wires and cables sector.

“At present, we’re planning to cater our products to the international market as well in the next financial year. In addition, we also intend to establish our presence in the railway cable segment for Indian Railway.”

Market Footprint

It has only been a few years since we’ve started manufacturing EBXL wires and cables and so far, we’ve received a positive response from the market. At present, we’re planning to cater our products to the international market as well in the next financial year. In addition, we also intend to establish our presence in the railway cable segment for Indian Railway.

Raw Material and Quality

Earlier, the e-Beam compounds were quite challenging as it had to be compatible with irradiation doses. However, nowadays, a few companies have developed indigenous e-beam compounds which are easily available in the market at competitive prices. These companies have a proven track record of the compounds they supply which maintain good quality.

Market Potential and Demand Shift

We see an enormous future for e-beam cables and it is only a matter of time that you’ll see these types of cables being used in almost all the applications. We have actually started our beaming division as a service provider and we’ve touched almost every cable company to start manufacturing e-beam cables. In fact, five years ago, there were only a handful of pertinent machinery in India, and then we came up with an idea where other cable manufacturers could bring their cable at our premises and we undertake the curing process for them. The trend so far has been good and we’ve been receiving a positive response from the industry.

“This is a Green Technology which helps to enhance product life and performance in adverse conditions, is very efficient, and enables us higher throughputs.”

Advantages Over Conventional Curing Process

Talking about the advantages, the technology is well accepted throughout the globe as the process is easily controllable with very tighter tolerances. It gives higher productivity which enables one to reduce the operating costs and also increases the life of a cable. Since the process does not require any additives, it doesn’t generate any hazardous chemical by-products. This is a Green Technology which helps to enhance product life and performance in adverse conditions, is very efficient, and enables us higher throughputs.