Ajex & Turner is a fast growing technology driven unit engaged in the manufacturing of wire drawing dies and die polishing, reconditioning machineries and their consumables.

Product Range & Application Areas

Ajex & Turner is a technology driven unit established in 1962 and is engaged in the manufacturing of wide range of consumable products for wire and cable industry. Our product range includes Wire Tube Drawing & Compacting Dies for PCD, ND, VNT Nano, Carbide, Sector, Trapezoidal, Die Polishing Machines, Spiral Brush, Buncher Bow, Carbide & PCD Tip & Die, Ceramic Bush & Pulley, Diamond Slurry, Angular & Wooden Pins, Measuring Pins, Cylindrical Pins, Air Wipers etc.

New Developments

VNT Nano Dies: Replacing the traditional ways of wire drawing and compacting, Ajex & Turner has engineered revolutionary VNT Nano Dies for copper, aluminum, aluminum alloy, stainless steel, welding, high and low carbon wire.

VNT Nano Dies: Replacing the traditional ways of wire drawing and compacting, Ajex & Turner has engineered revolutionary VNT Nano Dies for copper, aluminum, aluminum alloy, stainless steel, welding, high and low carbon wire.

With high demand in wire and cable industry, there is a call for a new science to draw materials with both good wear resistance and good surface properties, such that the quality of the drawn product is not compromised. The revolutionary nanocrystalline technology is the answer of all the advance needs of wire and cable industry.

Sector and Trapezoidal Shape Dies: We specialize in designing Trapezoidal and Sector Shaped Conductor Dies with respect to quality standards to meet customer requirements in all aspect of technologies on receipt of final conductor dies.

Sector and Trapezoidal Shape Dies: We specialize in designing Trapezoidal and Sector Shaped Conductor Dies with respect to quality standards to meet customer requirements in all aspect of technologies on receipt of final conductor dies.

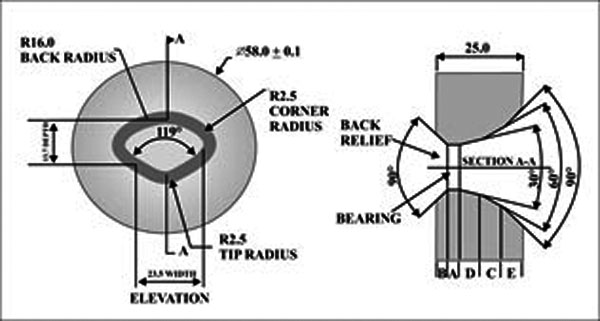

We are capable to serve our customers with any special tooling like shape drawing dies (trolley, oval, rectangular, square, triangle etc.) and compacting, bunching, stranding in Nano & PCD. Fundamentally, this type of die is used in the wire design and cables manufacturing industries. However, it includes some other areas also and special products that the customer needs.

Quality Control and R&D: Ajex & Turner is equipped with all kinds of advance manufacturing testing equipments and highly professional and experienced QC experts in application of wire drawing dies. We have close technological communication with all major domestic and overseas manufacturers of wire and cable industry. We deliver customized solutions to our clients as per their applications. With every new requirement of unconventional and special wire and cables, our R&D team rapidly dives into developing the new processes and technology which can ensure the better and improved production quality.

Indian Wire & Cable Industry Growth: The wires and cables industry in India has come a long way, growing from being a small industry to a very large one, over the past decade. The increasing demand for power, light and communication has kept the demand high for wire and cable.

Ajex & Turner is associated with Indian railways and metros to supply all tooling for wire and cable industry

Over the last 20 years, the industry has shifted from being an unorganized sector to an organized one. In India, the size of the cable manufacturing industry is approximately INR 40000 cr. The industry which has growth rate of 15 percent will start growing at the CAGR of 20 percent over the next coming years. This trend will continue as demand for reliable, efficient energy and data communications will strengthen the wires and cables industry in the future as well.

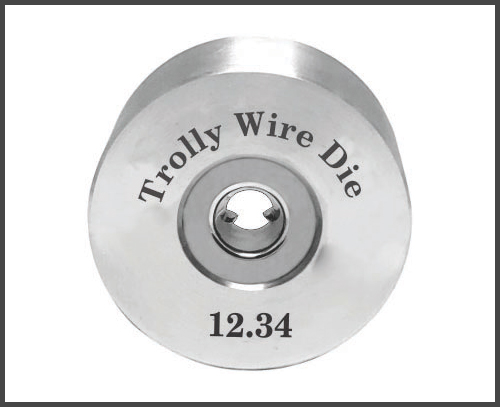

The infrastructural push led by government in railways and metros has lead to a rise in the demand for wire and cable. The need for special wires for metro rail and bullet train project has created an additional opportunity for the wire and cable manufacturers. Our trolley wire dies are developed to cater the same requirement. Running on our trolley wire, the newly launched high speed trains are fulfilling the dream of every Indian.

The infrastructural push led by government in railways and metros has lead to a rise in the demand for wire and cable. The need for special wires for metro rail and bullet train project has created an additional opportunity for the wire and cable manufacturers. Our trolley wire dies are developed to cater the same requirement. Running on our trolley wire, the newly launched high speed trains are fulfilling the dream of every Indian.