The company adopts thermal treatment procedures to make all kinds of extrusion toolings applicable to all types of machineries. To resolve the issue of smaller diameter conductor, Ajex & Turner’s trapezoidal-shape dies can be enlarged to provide a greater cross-sectional area

March 21, 2022

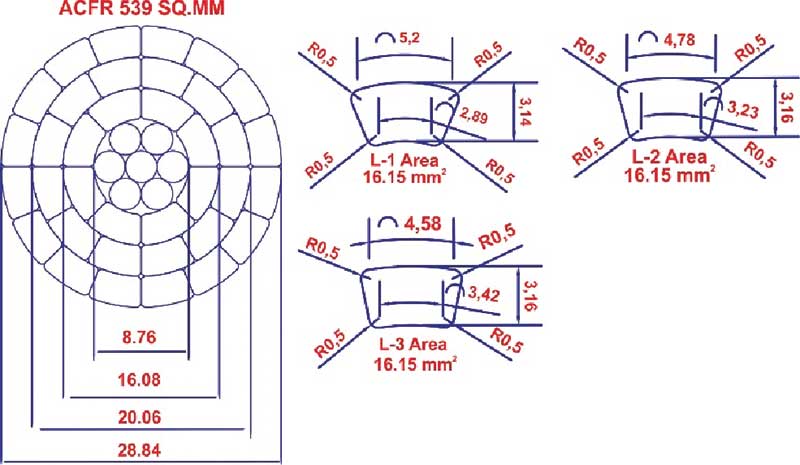

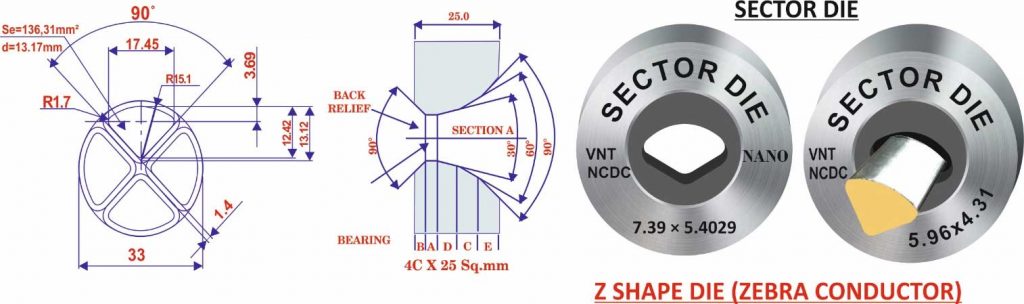

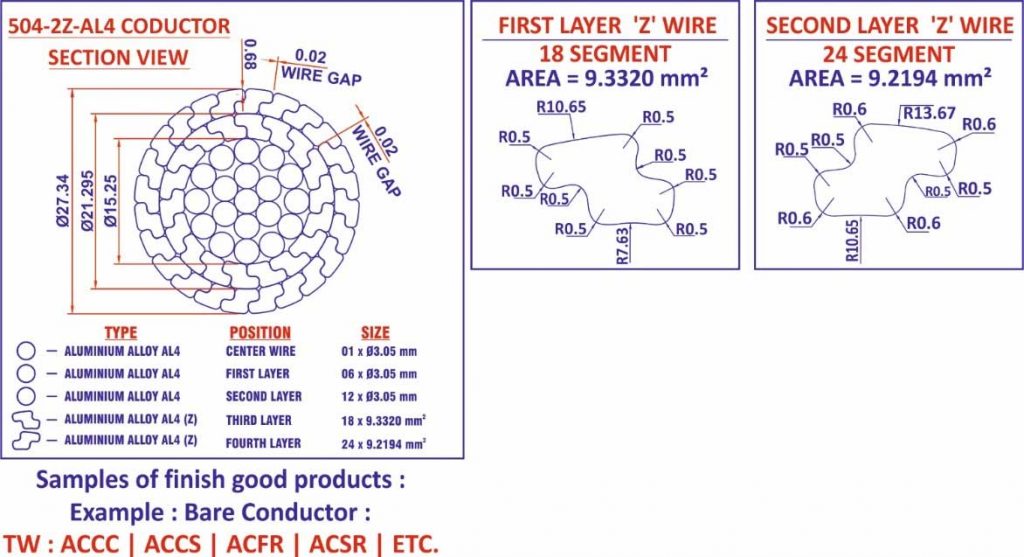

Ajex & Turner Wire Technologies designs trapezoidal wire (TW) dies in PCD, VNT Nano, Carbide to draw aluminum strands to produce ACSR, ACCC, ACSS, ACFR conductor (trapezoidal wire) as per ASTM standards approved by most of the power grid corporations throughout the world.

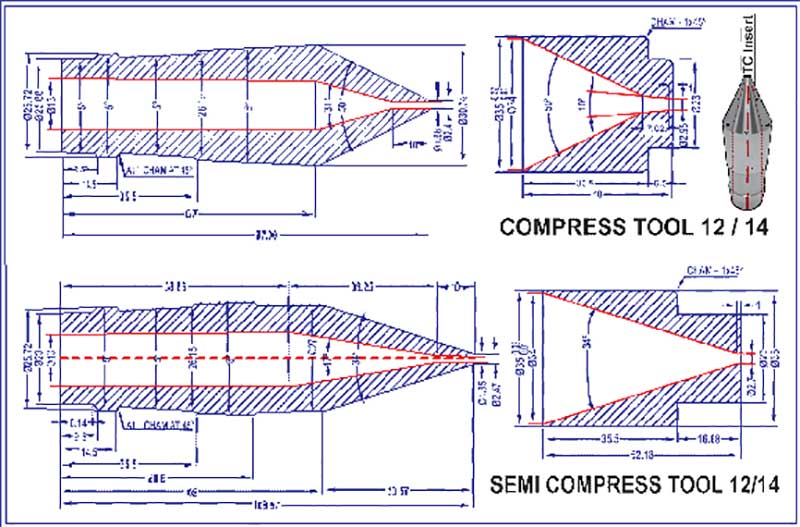

The company’s TW dies are designed to ensure accurate quality parameters to obtain aluminum strands that are shaped to provide a smooth outer surface that can meet applicable ASTM standards. The dies are made from high-quality raw materials that enable them to be both efficient as well as long-lasting. The drawing shows an example of TW-shaped compacting.

To resolve the issue of smaller diameter conductor, Ajex & Turner’s trapezoidal-shape dies can be enlarged to provide a greater cross-sectional area of aluminum and match the diameter of the conventional round conductor. TW and Z-shaped dies are used for compacting, bunching and stranding lines.

Watch: Wire & Cable Industry Year Review

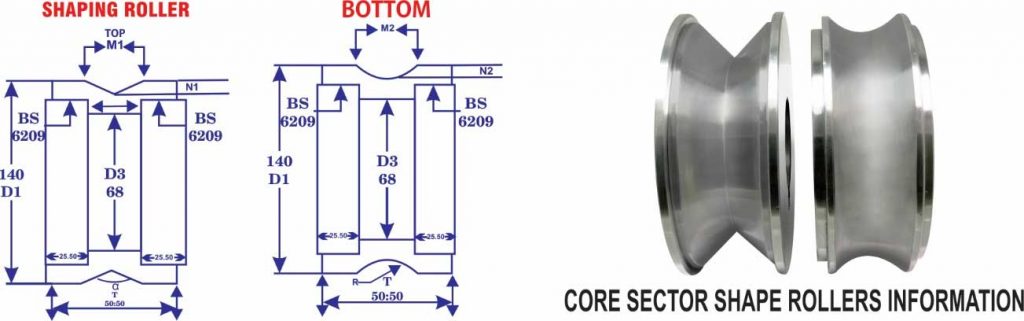

The company also produces sector roller, compacting roller as per conductor designs. 3, 3.5, 4 mm Core Sector shape compaction roller for 25, 35, 50, 70, 95, 120, 150, 185, 240, 300, 400 mm2 in 60º 90º & 120º or as per customer requirements.

Also Read: Ajex & Turner Launches Lubricants under Brand Name Masterlube

Ajex & Turner extrusion tips and dies are used in the manufacturing of power cables, control cables, telemetering systems, telecommunications, optical fibre, speaker cables, etc. The extrusion tips and dies are made in various shapes and sizes with very high quality, rust-free steel with tested ideal OD & ID concentricity. The highly maintained concentricity allows wire insulators to meet the demands of today’s super thin-wall constructions. These tools are made in alloy steel, carbide & diamond as per customer’s requirement. The company adopts thermal treatment procedures to make all types of extrusion toolings applicable to all type of machineries.