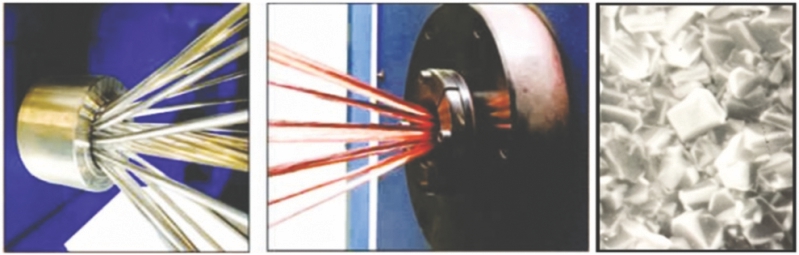

VNT nano dies by Ajex and Turner are made with multi-layer coatings of nano crystalline diamond through vapour deposition.

Ajex and Turner, a technology-driven unit, has been engaged in manufacturing a variety of wire drawing and compacting dies & tools for the wire & cable industry since 1962.

VNT nano dies are made with multi-layer coatings of nano crystalline diamond through vapour deposition, which provides an extremely smooth surface with immensely low friction. VNT nano dies can be made from size 0.5 to 100 mm for drawing, compacting, TW, sector and Z-shape wire.

Watch: Cable & Wire Fair Show Reel

Uses and Advantages of VNT Nano Dies for Wire Drawing & Compacting

- To draw copper, aluminium for stranding, compacting, bunching, rod break down (RBD) sizes, sector, TW, Z-shape wire, etc.;

- To draw aluminium alloy wire, nickel silver wire, brass, copper tubes or any metal;

- To draw stainless steel, high and low carbon steel wire up to 0.6 percent C, welding wire or any hard/soft wire of any size & hardness;

- Lower friction – better copper and aluminium utilization;

- Better surface quality – high and bright surface finish;

- Die range: 0.700 to 100 mm possible;

- Improvement of 3-4 percent in raw material utilization & better life than PCD and tungsten carbide dies;

- 0 percent tolerance for entire working life for any metal;

- No die polishing, re-cutting required for any metal;

- For aluminium and copper RBD process, nano dies are better for continuous process with no metal loss & tolerance breakage or scratch on the wire;

- The prices are 10 percent to 50 percent lower than PCD dies (depending on bore diameter);

- Casing – stainless steel grade 304 to avoid rust.

Also Read: Ajex & Turner Develops Extrusion Tips & Dies with Ideal OD/ID Concentricity

Why Nano Die is Better than TC & PCD

- For TC – While using tungsten carbide die for soft or hard material, there are chances of dust accumulation in the die and wire breakage and scratches on the conductor;

- For PCD – While using polycrystalline diamond die for soft and hard wire drawing purpose, above mentioned problems can be rectified, diameter can be controlled but variation is possible after a due course of time, but the nano die maintains 0 percent tolerance throughout its working life, thus, there is no need for re-polishing & re-grinding. Moreover, nano die is more economical in price than PCD & production is equivalent. With low power consumption, it saves 2-3 percent of metal.