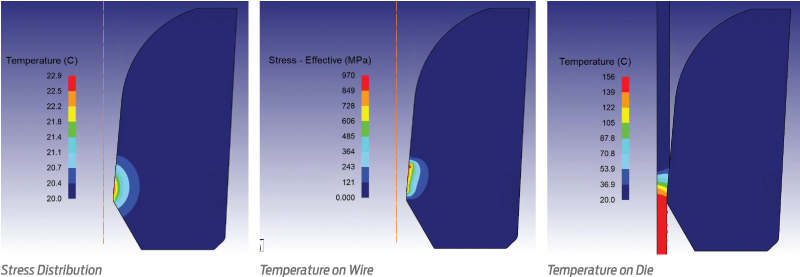

Kennametal works closely with customers in designing the die with advanced simulation support to suit the application with various profile offerings for wire drawing dies.

The process of wire drawing, which involves reducing the cross-section of a rod or wire by passing it through a series of drawing dies/plates, has not changed much over the years. However, there has been a marked evolution in the tools used during the drawing process, elevating the technology altogether. Several studies on tool geometry, tool material, and tool wear indicate that the quality of the drawn wire, bar, or tube and the economy of the process depend, to a large extent, on the tools implemented. Further, in the present day, to meet the demand for increased productivity, very high drawing speeds are needed. For these applications, tungsten carbide tools are being increasingly employed to meet these demands.

Die Performance

Selection of the right die with optimum parameters like entry angle, reduction angle, bearing length and exit angle are crucial to the performance of the wire drawing, along with the carbide grade.

During the drawing process, a number of variables can influence the die performance—these can be broadly divided into two groups:

• Independent variable

• Dependent variable

Independent variables are all those variables that can be governed directly, like drawing speed, type of lubricant, the geometry of the die, percentage reduction, and die material.

Watch: Wire & Cable Industry Year Review

Dependent variables are those variables that cannot be governed directly, as they are caused by the process of drawing itself, like co-efficient of friction, wire temperature, variation in shear strength of the lubricant at elevated temperature, drawing stresses, plastic strain in the wire, power consumption, etc.

Drawing dies are subjected to severe abrasion, compressive forces, thermal stresses, and chemical reactions. Therefore, in order to monitor the drawing process, the user has to monitor dependent variables very accurately in order to successfully reach the root cause of the problem of ’independent variables’. For example, poor shear strength of the lubricant used will result in higher wire temperature at every stage of successive draw benches. A check on wire temperature, however, will give an indication of proper lubrication and/or change in the coefficient of friction in the drawing zone. Similarly, increases in draw stresses would result in wire breakages or poor surface quality. With the right instrumentation on the draw, benches and dependent variables can be monitored reasonably accurate.

Kennametal works closely with customers in designing the die with our advanced simulation support to suit the application with various profile offerings for wire drawing dies (bell type nibs, long nibs, ISO nibs, pressure dies).

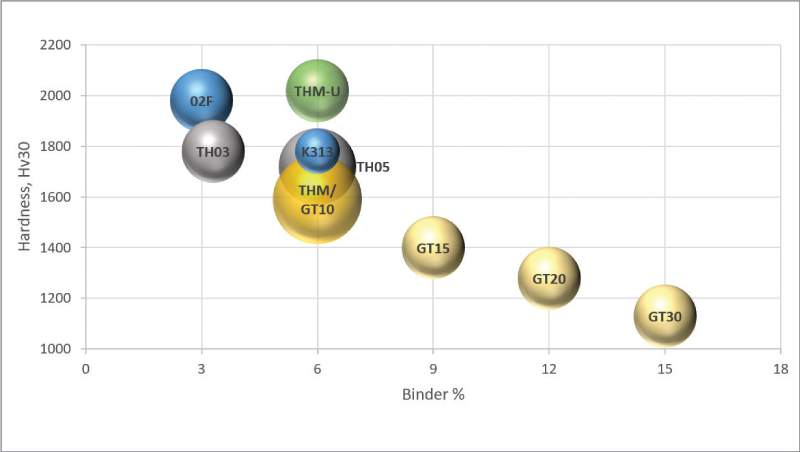

To boost performance parameters, Kennametal offers drawing dies in various grades, ranging from 3 percent to 15 percent binder grade for use in dry and wet drawing applications. We also offer other products specific to this industry, like cone rings (used in Wet Wire Drawing Machine), straightening rollers, descale rollers, shaving dies, scarfing tools, guides, tungsten carbide hard facing electrodes (for drum coating in dry wire drawing) for use in allied wire drawing applications.

Our advantage is our deep understanding of materials–it is not just our ability to supply a part made from a particular material, but it is the thorough evaluation process followed, backed by the indisputable science behind our work.