As a major producer of drawing die-tools, Eder began designing and developing die processing equipment for its own use, only to become a leader in the field of such equipment.

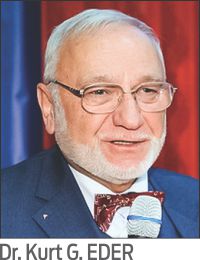

EDER-Austria, with about 98 percent export quota, holds one of the leading positions in die-tool processing technology and equipment, offering semi- and fully automatic conceptions for both the production and/or reconditioning of ultra-hard precision die-tools made from tungsten carbide, natural diamond and synthetic PCD. WCI recently interacted with Dr. Kurt G. EDER, President/CEO, EDER Engineering GmbH. Excerpts:

EDER-Austria, with about 98 percent export quota, holds one of the leading positions in die-tool processing technology and equipment, offering semi- and fully automatic conceptions for both the production and/or reconditioning of ultra-hard precision die-tools made from tungsten carbide, natural diamond and synthetic PCD. WCI recently interacted with Dr. Kurt G. EDER, President/CEO, EDER Engineering GmbH. Excerpts:

Wire & Cable India: Congratulations on Eder’s completing 70 years! How has been the journey so far? Tell us important milestones the company achieved during these years.

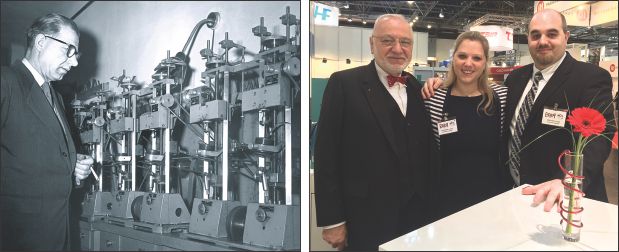

Kurt G. EDER: Since its inception in 1947, EDER Co. in Vienna/Austria started with the production of tungsten carbide drawing die-tools and die working equipment for own use. In 1949, it started natural diamond dies production followed by first exports of die-tools to neighboring countries, e.g. Germany, Yugoslavia, Hungary etc. in 1950. Thereafter, in 1952 first sales of die-tool working machines abroad took place. In 1956, EDER Co. participated in an Austrian-USSR industrial exhibition in Moscow which turned out to be a great success. In 1960, the company started exporting 60 percent of dies and machines to Europe and overseas.

In 1965, EDER got into contact with the first man-made industrial diamond materials and tested them about their usability for die-tools. Further, in 1966 the company developed the first Ultrasonic Die Working Equipment with up to 600W power (model USP-110). In 1968, it started with the production of the first PCD (Compax) die-tools and in 1970 EDER Co. started with the sale of high powered USP-110 ultrasonic machine to work PCD dies.

In 1974, it made Dicamat EDM equipment to drill and shape PCD dies without needing Laser. In 1976, there was swivelling die turntable invention, allowing mirror-polishing of PCD dies. Furthermore, in 1980, the company came up with first HGM wire type sizing/polishing unit with a unique speed of 900 strokes/minute.

In 1988, first PCD compacting die-tools were supplied to the Siemens Cable Group. In 2010, the design of the EDDS-system for marking of dies came into picture to protect property rights. Then in 2012, EDER produced USP-TWIN the first ultrasonic die working machine offering two workstations to cut processing time and double output, while being handled by only one operator. By 2015, 98 percent of company’s exports went to over 80 countries worldwide. Today, in 2017, we are celebrating 70 years of EDER-Austria.

WCI: Isn’t it true that Eder started as a die/die-tool manufacturer and later shifted to mainly making die working machines and software? How did that transition happened?

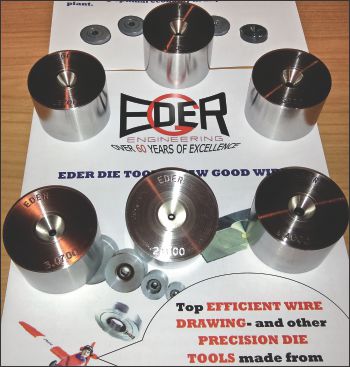

KGE: More than 90 percent of our production now is in special machines for both the reconditioning and production of dies, while our former involvement in making dies meanwhile has been internationally reduced to a relatively small number, mainly for specific die-tools, which not everybody can do easily. To make a proper PCD die is no longer a miracle. All one needs is a fundamental knowledge of how a proper die-profile must look, obtain suitable raw materials for dies and use efficient die processing equipment. One can easily recognize this by seeing the mass of new die makers, mainly from Asia, rushing into the global market for die-tools and often with lower prices, as labor, energy and production cost are considerably cheaper there.

WCI: Will you please update us on how Eder pioneered new machines for polycrystalline diamond (PCD) dies and popularized more efficient PCD dies globally?

KGE: Shortly after G.E. had succeeded in developing their synthetic “COMPAX man-made diamond material”, initially for cutting-tool applications, in the early 60th, EDER started a confidential cooperation with them to find out whether or not this synthetic material would be suitable to be used for wire drawing die-tools also. This testing period soon showed us that the then available equipment was much too weak and underpowered to grind and shape these synthetic diamonds efficiently. This was the spur for developing a totally new generation of considerably more powerful machines and techniques, resulting in the availability of the USP-110 ultrasonic, HGM high speed wire type and the DICAMAT special EDM equipment then.

WCI: As a wire drawing machinery and tools experts, update us about the latest technological trend in your area of expertise. Is Eder Engineering able to meet all those latest technological developments through its product portfolio? (Please answer citing examples, i.e. products with latest technology.

KGE: The rate at which diamond/PCD dies need to be reconditioned is increasing as more wire drawing manufacturers use high-speed, multi-wire drawing machines, now available with up to 48 wire lines on a single machine already. These machines use several expensive dies simultaneously, wearing them out relatively quickly so that they have to queue for reconditioning at die workshops where skilled operators or suitable die reconditioning equipment are often in short supply. The growing number and importance of precision drawing die sets in use and their regular and perfect reconditioning becomes an absolute criterion if drawing efficiency in multi-wire drawing machines is to be maintained at a necessary high level. To avoid bottlenecks in die workshops, when costly dies are lining up for refurbishment and renewed use, EDER-Austria with 70 years of experience has designed two special machines, each of them with two independent workstations.

KGE: The rate at which diamond/PCD dies need to be reconditioned is increasing as more wire drawing manufacturers use high-speed, multi-wire drawing machines, now available with up to 48 wire lines on a single machine already. These machines use several expensive dies simultaneously, wearing them out relatively quickly so that they have to queue for reconditioning at die workshops where skilled operators or suitable die reconditioning equipment are often in short supply. The growing number and importance of precision drawing die sets in use and their regular and perfect reconditioning becomes an absolute criterion if drawing efficiency in multi-wire drawing machines is to be maintained at a necessary high level. To avoid bottlenecks in die workshops, when costly dies are lining up for refurbishment and renewed use, EDER-Austria with 70 years of experience has designed two special machines, each of them with two independent workstations.

The first of these conceptions is the unrivalled ultrasonic machine, model USP-TWIN, with two workstations, allowing a single operator to recondition two dies at the same time, such practically doubling output. One workstation (UF) handles smaller dies (from 0.05 up to 3 mm dia.) and the other one (F) handles medium to large dies (1 to 8 mm dia.).

For the subsequent sizing/calibration of the dies´ bearing portion and to keep pace with the larger quantity of dies, arriving from the aforementioned USP-TWIN equipment, the special HGM-21 high speed, wire-type machine has also been tailored to size and polish all diamond/PCD dies with bore-diameters between 0.05 up to even 10 mm perfectly. Both of these machines are easy to understand and operate and do offer both an outstanding versatility and potential for all die-workshops.

It is obvious that these outstanding EDER-conceptions therefore can easily meet all relevant needs and requirements.

WCI: You have a comprehensive global footprint roughly over 80 countries. How has Eder been able to cover this vast geography for export? Kindly give an outline of your major markets with respective product range exported there.

KGE: From 1950 onwards, products of EDER-Austria got exported and appreciated due to their outstanding quality. At first most of these supplies went to neighboring countries, such as Germany, Hungary, Yugoslavia etc. Increasing travelling activities, the knowledge of foreign languages as well as participations in technical symposia and industrial exhibitions soon also created a global reputation and international recognition.

EDER´s CEO, Dr. Kurt Eder, being the founder and president of the AWCMA/VOEDKM (Austrian Wire & Cable Machinery Manufacturing Association) and vice president of “IWCEA”, its international counterpart, until today, frequently presents lectures and technical papers worldwide.

WCI: If asked to give a global perspective on wire-drawing practices across various countries, which region would you rate as the adopter of best drawing practices and technology? What do you say about India?

KGE: In this respect, Central Europe and Scandinavia certainly is foremost in using most advanced wire drawing technologies and practices, with the USA coming second. There is a lot of improved practices also taking place in some parts of Asia, such as China and India.

WCI: How is India as a market for Eder? Some strategy or plan for the Indian market?

WCI: How is India as a market for Eder? Some strategy or plan for the Indian market?

KGE: While the Indian market is definitely poised to grow, judging from our experience in exhibiting in various ‘Wire India’ shows throughout the recent years, regrettably, we have found that – contrary to other growing markets in Asia – in India one still prefers to use simple, often locally made die-tool processing machines and technologies and accepts cheap purchasing prices only, while demanding high quality and performance. A real contradiction as quality always does require a certain price level for sure. In our opinion and that of most of my colleagues in Austria, a lot of water will still flow down the Ganges, until this mentality will change, but it certainly will.

WCI: Do you have something to say on global wire and cable manufacturing outlook in coming 3-5 years?

KGE: Mankind, and particularly in our industry, is a rather conservative human being. However, wire drawing and cable producing technologies and equipment have reached a remarkable standard of outstanding performances in most developed countries and in respect of tonnages and quality levels already. It is just a matter of time, education, experience and budgets available, until even growing markets will reach these targets too. Neverthe-less two axioms will always remain: a). it is the perfectly produced or repaired wire drawing die, which is drawing the wire, and b). those who invest in time and in quality will succeed.