To achieve higher efficiency in a pickling, rinsing and effluent treatment plant, we need to control acid carry-over and reduce the ETP load.

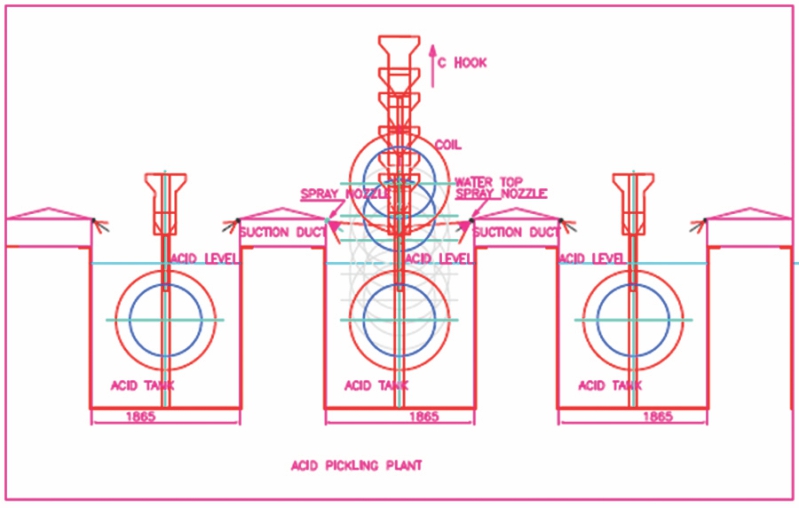

The set-up layout of typical sulphuric acid pickling is shown in the drawing given below:

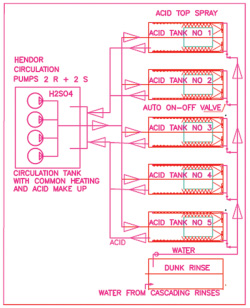

There are five acid process tanks and one service tank which circulates acid by Hendor pumps from service tank to all process tanks and gets back acid in return by gravity. Hot rolled wire rod steel coil gets pickled in one-dip immersion treatment in sulphuric acid pickling. In hydrochloric acid pickling, there is cascading acid and hence coil is immersed in all acid tanks to complete the acid treatment. The four rinses – dunk, spray and two more immersion rinses – have water flowing back in cascading to give maximum cleaning.

There are five acid process tanks and one service tank which circulates acid by Hendor pumps from service tank to all process tanks and gets back acid in return by gravity. Hot rolled wire rod steel coil gets pickled in one-dip immersion treatment in sulphuric acid pickling. In hydrochloric acid pickling, there is cascading acid and hence coil is immersed in all acid tanks to complete the acid treatment. The four rinses – dunk, spray and two more immersion rinses – have water flowing back in cascading to give maximum cleaning.

The beauty of this arrangement of acid tanks lies in the fact that equal concentration and equal temperature of acid in all acid process tanks can be achieved, as the tanks have the same acid getting circulated from the service tank, which has a centralized heating arrangement. Acid dosing is done after each coil is processed by auto dosing. The immersion time is decided and controlled by the robotic automatic crane controlled by PLC. Therefore, each coil has equal time, temperature and concentration treatment for the first to the last coil of the day.

The level of iron varies in operation from 40 to 70 g/l as optimum level in the acid tank. The iron-separation process is continuous. It starts at 70 g/l and returns regenerated acid after iron removal up to 40 g/l level to the service tank.

The acid carry-over from coil (usually 100 micron thick layer of water on surface of rod and surface area for a 11 mm rod coil per ton is at 46 sq m; there is 4 to 5 liters per ton carry-over) contains 25 % concentration of acid of process tank with 70 g/l as the iron level. This contaminates the rinse bath to the maximum extent and causes the first dunk rinse to have acid concentration build-up to 5 to 6 %. The contaminants are acid and iron to the first dunk rinse.

It is important for phosphate bath to have minimum contamination of iron from rinse water in order to control sludge formation. The disadvantage of H2SO4 pickling is that iron carryover pollutes the phosphate bath. On the other hand, HCL pickling runs with cascading and that means the bath for last immersion of coil has zero iron and maximum concentration of acid; this helps to avoid any carryover of iron. In sulphuric acid pickling for each tank, the iron level varies from 40 to 70 g/l, which gives an additional source of iron addition into rinse and subsequently into phosphate.

It is, therefore, important to reduce acid carry-over into rinse. Traditionally, one rinse tank when added reduces acid concentration on the coil for carry-over. But it requires additional space and cost for the added tank, and it increases crane movement and water consumption. Here comes the innovation! Acid tank top spray! The rinse water is sprayed onto the coil when it comes out of the acid tank. The acidic rinse water, which has about .5 to 3 % concentration, washes the acid on the coil that has acid at 25 % concentration and the same is falling back into acid, hence acid returning to acid. The washed liquid falls back into the acid tank. This results in reduced acid consumption, reduced load on ETP as less acidic water goes to ETP and reduced water consumption.

When rinse water is added to acid by top spray, the acid level may go up if a controlled quantity is not used for top spray. The quantity of water added to acid must be less than the makeup requirement for the level in acid tanks. Makeup is required to balance or maintain the level in acid tank because there is loss due to evaporation, carry-over from each coil processed and loss of water molecules in ferrous sulphate heptahydrate during the acid-regeneration process. These losses of water are quantified by calculating them. The evaporation loss is calculated by knowing acid temperature at 50 deg c and the exposed acid surface area. The water lost in ferrous sulphate heptahydrate crystals is know by molecular weight balancing such that 2.3 kg of water is needed for every kilogram of iron dissolved . After calculating the water makeup requirement, the spray nozzle flow rate can be designed. The spray nozzle is selected for a specific flow rate and should be of clog-free design. Spray nozzles made by BETE are used. The top spray pipe is positioned above the tank so that when the coil starts to come up from the acid tank, the pump and spray start; and when the spray no longer touches the coil, the spray stops. The commands for start, for stop of spray and for each acid tank are given through the main PLC and by feedback from crane. There is an auto on-off valve in the spray line for each tank. The coil is held in top position above the acid tank for 30 seconds to allow the water to drain off the coil surface.

The rinse water, when reused for washing by spray on acid tank, is not fresh but acidic rinse water. This reduction in acidic rinse water reduces the load on ETP. The rinse water pump is connected to the first rinse after acid to spray back the acidic water into the acid tank. The dunk rinse has sludge at the bottom and so the tapping for suction of pump is taken from a little higher to avoid nozzle clogging.

Maintenance of level in acid tank is important for trouble-free operation of pump. The Hendor pumps need a higher level in acid tank – 65 % as the minimum starting level. Later, they can run on a level lower than the minimum starting level because of the suction pipe attached to them. The level switch gives alarm if there is low level for pump protection. The addition of top spray water into the acid tank usually matches the makeup requirement, but if some adjustment is required, the acid is pumped into the spent acid tank for a day and then taken back during the next day to meet the initial minimum pump starting-level requirement.

The diagram given below explains hydraulic fluid flow directions and quantities.

Acid consumption with the regeneration process in place generally varies between 6 and 7 kg/ton but with the acid top spray process, acid consumption can be brought down to 4 kg/ton.

This system can be added to all existing pickling plants as well as new plants, as it helps to reduce acid consumption and the load on ETP.

This article has been written by Jayant Gokhale,

Senior Manager, Projects, Tata Steel Limited, Global Wires, Tarapur.