In 2006, Usha Martin formed a strategic partnership with Pengg Austria GmbH to produce oil-tempered wires to substitute the import in the country and to cater to the demand of the whole of Southeast Asia. To explore more on this partnership and the idea behind it, team WCI had a joint interaction with Mr. Alexander Phillipp, Managing Director, Pengg Austria GmbH and Mr. P. K. Jain, Joint Managing Director, Wire & Wire Rope Division, Usha Martin Ltd.

About Joint Venture & its Synergies

Pengg Austria GmbH is a well recognised oil tempered (OT) wire producer having the rich legacy of 300 years, and Usha Martin Ltd (UML) is a world leader for wire ropes and wire products. Usha Martin has lot of market experience in wire ropes and wire products here in India and abroad, and JV partner Pengg Austria brings its technical know-how for oil-tempered wire production. These individual strengths of business brought them together to form the JV for ‘Oil Tempered Wire’. As a result, both these organisations have strong experience, which is reflected in the global quality product at domestic prices.

This JV has brought in synergies for both of them. First, the product basket that the UML group now offers has another feather in terms of OT wire, till date not offered by any Indian company. Second, Pengg Austria now has a footprint in this part of the continent allowing clients to have world class products that can be supplied at a very short time/JIT basis.

Oil Tempered Wires and their Application

Oil tempered wires mainly find application in the automobile sector for making critical springs like springs for transmission and engine valve. These wires find a variety of use, particularly due to extremely high tensile strength and very good ductility. This JV is a Greenfield project to produce oil tempered wire for the first time in the country, which was earlier imported. The main USP of this project were as follows :

• Saving the domestic spring manufacturers from demand fluctuations and market risk.

• JIT stock which was not possible through import route. Besides, the auto market has tremendous seasonality of demand, which only a local vendor can meet.

• Serviceability – peace of mind to all domestic vendors to be at their beck and call for any service requirement.

Springs for automobiles are produced through the cold and hot deformation method. Cold deformation results in production of springs of high accuracy and higher fatigue life compared to hot coiling/hot deformation produced springs. Springs of OT wire is produced by the cold deformation method and can be used for static and high dynamic applications and can withstand its properties even at elevated temperatures. OT wires are typically high tensile wires that find application in critical components of the automobile. As these wires have typically very high tensile strength, good ductility and homogeneous structure without any deformation texture, the springs have high fatigue life and good relaxation properties.

Technologies and Process Systems Adopted

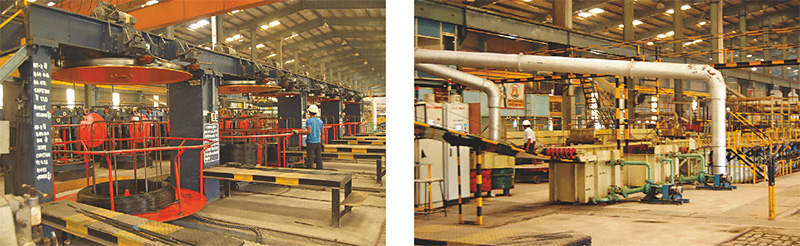

The JV decided to adopt the latest technology and the most advanced systems available worldwide. Usha Martin produced the work centers in their state-of-the-art machinery division with technical inputs from Pengg Austria. The plant is fully automated with parameters being monitored and fed back in the self-correcting control system of the processors controlling the individual work centres. The process parameters are not left to human judgment and precision products are the final output. In fact, the process parameters of the Ranchi plant are exactly identical to that maintained at the Austrian unit. This has enabled them to nickname the Ranchi products with the same brand name “PENTHOR”, identical to that produced in Austria – as no variations exist. So, domestic clients are getting a world quality product. Process orientation is carried out throughout the company.

Future Plans

The company started its commercial production in Feb 2008 by installing the first line. Promoters were enthused by the demonstrated growth and a second line was commissioned in 2011. We can further enhance the capacity at a very short notice; as soon as demand picks up with the revival of the economy, we will ramp up our capacity.

Views on Indian Auto Industry

Although at present the auto sector is going through a difficult time, we are convinced that we will see a positive development in coming years. We have already seen how a good monsoon has contributed to the boost in tractor sales off take in the last couple of months. Likewise once the overall economic scenario looks up, the auto sector will also have a much better prospect; and long-term future is bright. In spite of the sluggish outlook India is set to become the third largest automotive market in the world. By 2016 it will be ahead of Japan, Germany and Brazil, riding on its domestic automotive sales as different industry reports claims.