India and China is going to be grounds for two major wire and cable exhibitions separated by hardly 10 days.

Wire and cable companies across globe are in flurry to catch up with both the events where they can showcase their products and recent developments to a large visitors’ footfall. wire China 2016 – The 7th All China International Wire & Cable Industry Trade Fair – is going to be held at Shanghai New International Expo Centre from September 26-29, 2016. Wire China show is co-organized and developed jointly by Messe Düsseldorf and its subsidiary in China together with Shanghai Electric Cable Research Institute and offers good opportunities for wire and cable businesses. Likewise, India would be host to Wire & Cable India 2016 at Bombay Convention & Exhibition Centre (BCEC), Mumbai, India from October 5-7, 2016. This show is also organized by Messe Düsseldorf and its subsidiary Messe Düsseldorf India.

Both the shows, over the years, have become important for visitors and exhibitors as platforms for showcasing one’s products and getting to know what others in the industry are doing in terms of product and technology development. The show in Mumbai this time is also convening a conference on ‘Polymers in Cables and Wires’ on October 7, 2016 at the same venue. The conference may be a window of knowledge on the increasing polymer usages and its functionality for many who are directly or indirectly in the polymer business for the wires and cables. WCI brings you a preview consisting of few companies ready to exhibit in the show.

AEI Machines to Showcase Its High Performance Rigid Standers at Wire & Cable India 2016, Mumbai

Design, engineering and excellence in manufacturing practices are the key elements for the making of AEI Stranding Machines.

Despite the market milieu for conglomeration of various machinery manufacturing units to groups, AEI Machines is the only manufacturer that remains solely focused on developing and manufacturing of Rigid Stranders. With more than 45 years of expertise in the field of rotating machines and with a team of experienced engineers and skilful technicians, AEI Machines offers Stranders that deliver higher production speeds and superior final product quality while ensuring operator safety and minimal maintenance.

During Wire & Cable India 2016, AEI shall showcase its Rigid Stranders which deliver accurate back tension, smooth strand deviation and precise lay control. These features are essentially required for quality compacted conductor in case of low, medium and EHV power cables and for high production speeds in case of overhead conductor manufacture. Enhanced cage speeds and use of fully automatic bobbin batch loading systems further ensure higher production efficiencies and uptime.

As the cost of manpower, energy and space increases, AEI looks forward to welcoming visitors to demonstrate the advantages of upgrading to AEI Machines.

AEI Machines will be at Wire & Cable India 2016 at Stand No. A52.

___________________________________________________________________________________________

Science Behind the Wire Drawing & Compacting – VNT Nano Dies & Die Maintenance

Ajex & Turner Wire Dies Co. is participating in Wire & Cable India and China Show 2016. The company is looking forward to the show as an ultimate opportunity to achieve the attention of its target audience.

Replacing the traditional ways of wire drawing and compacting, the company has developed revolutionary VNT Nano dies for copper, alu, alu alloy, stainless steel, MIG, high/low carbon wire.

With the boom in wire industry, there is a call for new science to draw materials with both good wear resistance and good surface properties, such that the quality of the drawn product is not compromised. The revolutionary Nanocrystalline technology is the answer of all the advance needs of wire industry.

Along with VNT nano dies, Ajex & Turner will also showcase our PCD dies, Carbide dies for wire drawing and compacting, Busbar Dies, Shape dies, Die polishing machines for PCD & Carbide, die polishing accessories, die inspection microscopes etc.

In-House Die Maintenance : The company’s revolutionary TCD-10 will keep you ahead in the area of die polishing and grinding as it grind and polish angles and bearing in one operation, which saves time, energy and also very cost effective. The machine operates at very high speed with air pressure spindle and can recondition dies in a very short time of period. It provides Accurate and Precise angles on re-cut dies.

Ajex & Turner believes that exhibiting in India and China shows, its products can be witnessed by maximum number of potential customers for a fraction of what it costs to visit 50 clients and prospects over the next 6 months. The company intends to highlight our new developments at show by product demonstration by technical discussion and showing the product working video.

Ajex & Turner believes in selling on value not price and are open for free trials as well.

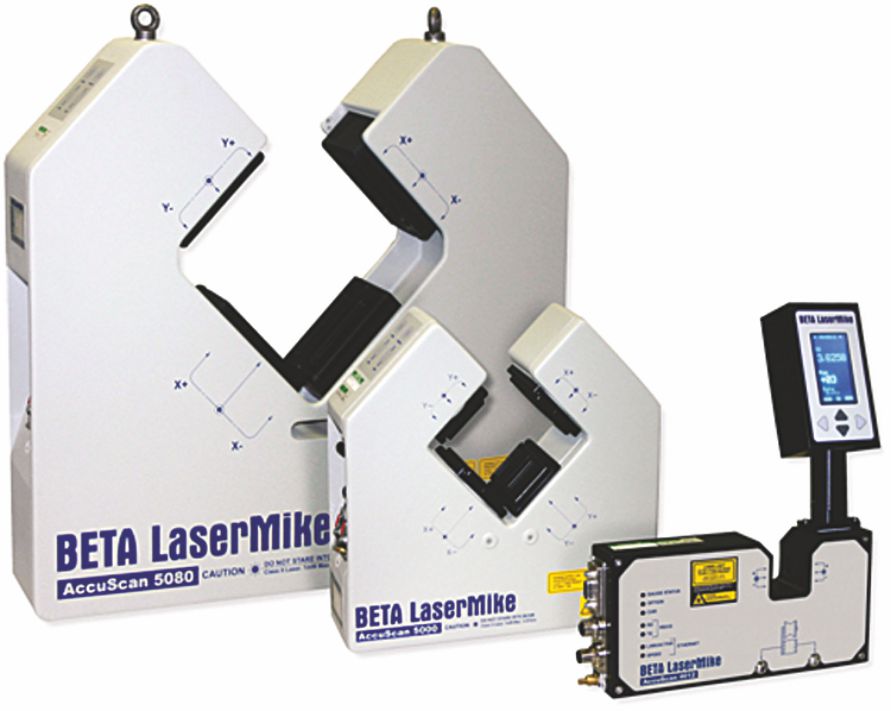

Predict Technologies India to Exhibit Beta LaserMike Products for Precision Measurement and Control at Wire and Cable India 2016

It will showcase several offerings from NDC Technologies’ line of Beta LaserMike measurement and control solutions. The lineup delivers higher accuracies, production efficiencies and savings for quality and profit-minded wire and cable manufacturers in India.

Predict Technologies will be exhibiting the family of Beta LaserMike AccuScan diameter and ovality gauges including the economical AccuScan 4012 single-axisgauge, AccuScan 5000 Series two-axis gauge and new AccuScan 6000 Series four-axis gauge. The AccuScan 4012 offers manufacturers a compact, economical gauge for measuring product diameters up to 12 mm with high single-scan accuracy. The AccuScan 5000 Series offers high-speed, highly reliable two-axis diameter and ovality measurements for products up to 80 mm. The AccuScan 5000 Series effectively monitors cylindrical round and special-shaped products for optimum process control and immediately catches product flaws with High-Speed Tolerance Checking. The new AccuScan 6000 Series is the industry’s only four-axis scanning diameter and ovality gauge that provides the highest ovality and flaw detection accuracy compared to 3-axis gauges. The AccuScan gauges provide highly flexible communications with easy connection to a host PC or PLC using RS-232, DeviceNet, Profinet, Profibus, Ethernet/IP and Ethernet TCP/ IP.

The most recent LN Series three-axis lump and neckdown detectors quickly and reliably spot product flaws before they become costly production problems. Fast-sensing and processing technology instantly detects sudden changes in the product diameter to effectively catch the smallest of flaws. The LN3015 detects flaws as small as 0.02 mm on product diameters up to 15 mm, while the LN3040 detects flaws as small as 0.05 mm on product diameters up to 40 mm. Both gauges can detect flaws at line speeds up to 3000 m/min. The LN Series can also use the line speed input to determine the flaw length and flaw location along the length of product. These detectors are designed with a user-friendly operator interface, accept a range of inputs and provide highly flexible communications.

CenterScan 2010 accurately and reliably measures the insulation diameter, thickness and conductor eccentricity of wire and cable to maximize product quality and reduce production scrap. CenterScan is compact for installation flexibility on the product line and easily integrates into production environments with built-in flexible communications. Users can easily access, view and configure gauge functions via an optional ultra-bright display.

The LaserSpeed gauge accurately measures the length and speed of products without making contact. This laser-based gauge delivers better than +/-0.05% accuracy and +/-0.02% repeatability, making it an ideal solution for replacing error-prone, high-maintenance contact tachometers. LaserSpeed models are available to measure both forward and reverse directions, as well as down to true zero speed (no motion).

Integral to the Beta LaserMike measurement system solution is the DataPro process controller and data management system. DataPro ties all the gauges together to continuously monitor product dimensions and automatically control the line to keep production processes and product quality under control.

Predict Technologies will also present BenchMike, theindustry’s leading off-line sample inspection system with over 15,000 gauges installed worldwide. Offering the highest accuracy on the market, this bench-top system gives operators a simple and repeatable system for measuring product samples and immediately determining whether they meet specifications within tolerances of less than 1 micron (0.000040 in.). BenchMike provides fast, accurate and repeatable dimensional measurements of diameter, multiple ODs, TIR, taper and part position.

Predict Technologies India is exhibiting at

Stand A103 at Wire & Cable India, Mumabi.

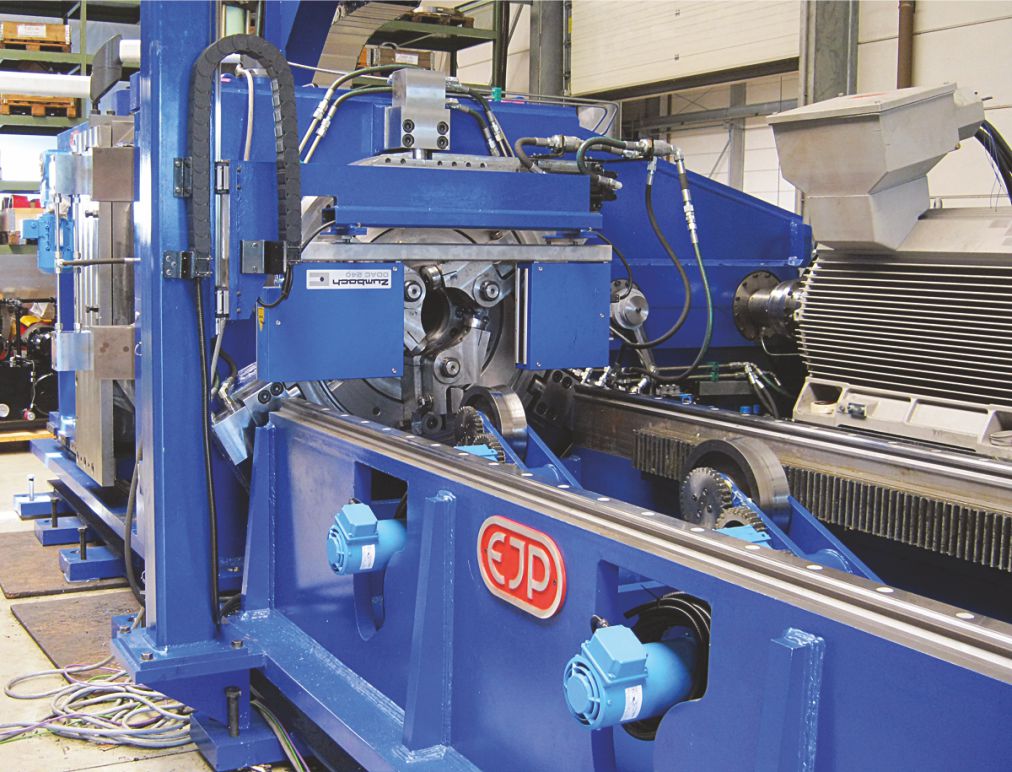

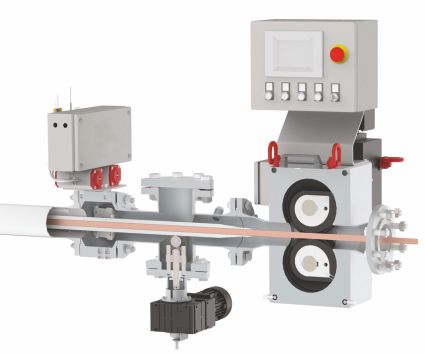

EJP is to Show its Further Developed Type PSP Peeling Lines for Solid Metal Bar at Wire China and Wire India 2016 Fairs

Peeling, straightening and polishing of solid metal bar; Double laser scanning boosts peeling process accuracy; End-product data feedback optimises peeling head adjustment.

The newly developed control system now installed adjusts the peeling head on the basis of the dimensions of the finished, straightened and polished rod. This makes it possible to control the process to ensure that the specified finished-product dimensions are met with extreme precision.

The new feature is measurement of the net dimensions of the finished rods and feedback of the results to the peeling process. Until now, the diameter of the peeled rods was measured only in the peeling machine. The measured data was used to adjust the peeling cutters to compensate for wear. The final dimensions had to be measured manually after straightening and polishing, since the straightening-process rolls could still then change the diameter. The resultant data could then only be entered time-consumingly and only on the basis of a subjective estimation by the operator.

EJP now equips these peeling lines with a second laser diameter measuring system downstream the two-roll straightening and polishing machine. This accurately measures the diameter of the finished product and relays it directly back to the peeling process. The control system registers the change in diameter in the straightening process and adjusts the cutters correspondingly. The result: rod products that conform precisely to the customer’s specifications.

Another new feature is the fact that EJP now measures the diameter of the rods in two laser axes, instead of only one. The operator thus also receives information on rod out-of-roundness.

Type PM peeling machines feature a patented peeling head which keeps the cutters stable under all operating conditions. A unique system adjusts the peeling head to compensate for tool wear; the cutters are adjusted by rotating the inner section, on which the cutter holders are mounted, in the outer ring of the peeling head. The guide elements for the outer ring are eccentric, with the result that the spacing of the cutters from the centre axis is set precisely by a simple movement of the two components relative to each other.

EJP in this way eliminates play in moving mechanical components, which can otherwise develop when racks and pinions are used. The cutters are readjusted under control even after long periods of operation, with the result that they are always accurately centred. This system also eliminates complex and costly maintenance.

Another benefit is the fact that the cutter holders are always fully supported within the housing of the machine as a whole. Unlike cone-based cutter guidance systems, they have no tendency to vibrate, particularly in the case of large section diameters.

New presence in India

Since April 2016, EJP has been represented in India by Kemtech International Private Ltd. This company specialises in metallurgical industry systems and machinery for the production of wire, cables and tubes, in particular. Anuraag Mahajan, CEO of Kemtech, has known the industry for decades and is therefore the high-capability contact for his country’s customers.Kemtech also deploys specially trained service technicians for servicing of EJP machines.

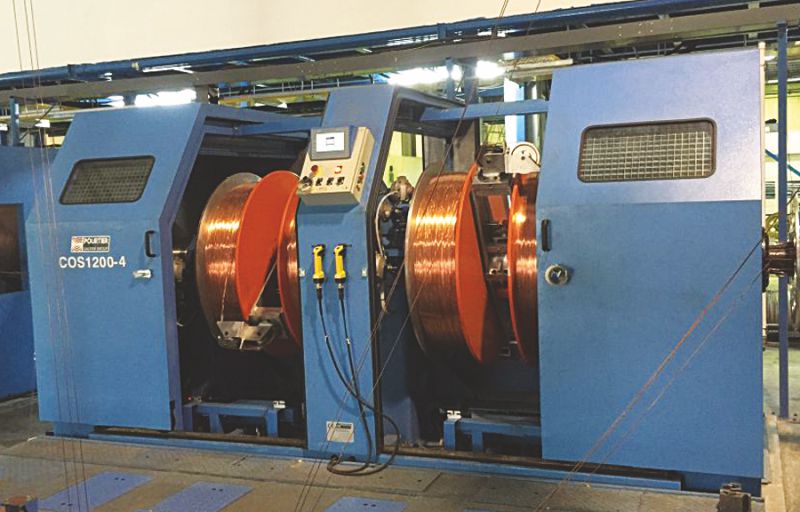

Gauder Group to Exhibit at wire Chine 2016

Worldwide leaders in rotating machines, POURTIER and SETIC – French members of the Gauder Group – are offering the widest range of twisting/stranding solutions to cable makers while DALOO, a Chinese member of the group, proposes medium-cost machinery based on the same quality standards. Services (C2S and Bow Technology) and used machines (GAUDER) complete the group range.

module of 4 reels with 3 wires each (POURTIER COS 1200-4).

POURTIER is a master buy with its heavy-duty stranders, cablers and armouring lines for ferrous and non-ferrous cables and has made impressive achievement in the field of submarine and umbilical cables with the supply of large armouring lines and laying-up lines. Its high efficiency revolutionary multiwire concentric stranding line is also widely used for low and medium power cable production. All these machines are made in Europe with the highest standards in design and manufacturing for the production of High Voltage and Extra-high Voltage power cable, from overhead to insulated, AC type (using high quality Milliken conductor) for land cable or DC type (using large round compacted conductor or trapezoidal wires) for both land and submarine cable.

self-traversing take-up,

mobile on floor

(DALOO SY 2000-8).

SETIC provides high-speed double twist bunchers/ stranders

for the automotive industry as well as complete solutions to produce high quality LAN, special and control cables with enhanced performances (in one step or two steps according to product mix) ; the Company is continuously developing new lines and new concepts for non-ferrous cables in order to meet the Customers’ needs such as tandem “mica taping/bunching”, special high speed lines for battery cable, new high speed lines for special and instrumentation cables. All these machines are made in France and some of them are also manufactured by the Gauder Group China division for direct supply to the Asian market, with the same quality standards.

DALOO is the logical extension of the group global offer for cable producers looking for an attractive alternative between

new machines made in Europe (with higher cost) and second-hand machines (without guaranteed performances). Its complete stranding lines and accessories for the production of power and communication cables are designed and made in China following Gauder Group proven methods and strict quality criteria.

Gauder Group will be exhibiting at

booth W1F25 at wire China 2016.

Kay Pee Dies to Showcase at Wire & Cable India 2016, Mumbai

Kay Pee Dies, established in 1968, produces tungsten carbide dies for wire, bar, tube drawing, cold heading, extrusion and special applications.

Dies and Lubricants are important choice for efficient wire drawing. The selection of proper dies and lubricants are two most important and essential requirement for wire drawing applications. This affects not only the quality, but also helps in reducing cost of drawing in terms of maintenance and the cost of drawing by increasing die life and reducing lubricants consumption.

The company serves customers from India, South East Asia, Nepal, the Middle East, and Africa. Moreover, since 2008, it has worked as an exclusive distributor for Panchemicals Spa, Italy for distribution and sale of its wire drawing lubricants and coatings.

Kay Pee Dies will be exhibiting at booth A-18 at

Wire & Cable India 2016, Mumbai.

___________________________________________________________________________________________

Lifeline Technologies to Display its Rodent/Termite/Ant Repellant Additive Chemicals at wire China 2016 and Wire & Cable India 2016, Mumbai

Lifeline Technologies offers an additive based on mixture of odor emitting chemicals and very bitter compounds unaccepted by rodents.

Rodent Repellent: About forty percent of all mammal species are rodents; they are found in vast numbers on all continents except Antarctica. They are the most diversified mammalian order and live in a variety of terrestrial habitats, including human-made environments. Rodents cause serious losses to agricultural, storage, houses, Cables, underground pipes and other commodities. All types of damages caused by rodents are not because their feeding activity only. Rodents have the constant urge to bite something to polish their incisors (front teeth), which is growing at the rate of 0.4 mm /day. These growing incisors are the most destructive to rodents. If they don’t gnaw frequently, their teeth can grow so long that they can no longer feed themselves and will starve to death. Hence, Rodents chew several products like cables, duct, plastic doors, wires, sidings, benches, molded plastic parts, drip irrigation pipes, etc. products due to presence of plasticizers, aromatic odors, bright colors and the texture of polymer products.

There are few species of rodent widely distributed in India, viz. the Indian gerbil, Tateraindica, the lesser Bandicoot rat, BandicotaBengalensis and the five stripped squirrel, Funambuluspennati. The lesser Bandicoot rat, BandicotaBengalensis is one of the most important rodent pest in Indian Agriculture, occurring in and around human settlements and also in fields and is cosmopolitan in distribution. T. indica is essentially a field rodent species distributed in various part of the country (except the hills).

There are two methods for testing of Rodent Repellent,

1. Choice Test – This is 30 days test in which rodents are exposed to a piece of cable, which is manufactured with rodent repellent. Food provided to rodent for 30 days and after the period of completion that cable piece is tested to check how many times rodent bite.

2. No Choice Test –This is 7 days test in which rodents are exposed to a piece of cable which is coated with rodent repellent. In this period of time only water supply to the rodent, after the period of completion that cable piece is tested to check how many times rodent bite.

Lifeline Technologies offers an additive based on mixture of odor emitting chemicals and very bitter compounds unaccepted by rodents. Rodent Repellent does not kill but only keeps the animal away by making use of the sensory mechanisms. The product functions from a distance due to the foul smell which generates a typical fear response in the animal. Rodent Repellent actually helps in modifying animal behavior.

Ant cum Termite Repellent: Ant/Termites are often called the “silent destroyer” because they may be secretly hiding and thriving in your home or yard without any immediate signs of damage. All termites consume cellulose-based plant materials. Unfortunately, all homes, regardless of their construction type, can provide cellulose food for termite infestation. A termite’s mouth is capable of tearing pieces of woody material. This ability is what causes concern in human dwellings: while termite workers only measure approximately 1 cm to a few millimeters in length, their feeding habits are capable of causing costly damage to property. Cables, ducts, pipes and plastics are all possible feeding sites for termites.

Thermoplastics materials have always attracted insects. The plasticizers & the aromatic odors of polymers, the bright colors & the texture of polymer products attract insects.

Lifeline Technologies offers an additive based on mixture of odor emitting chemicals and very bitter compounds unaccepted by ants & termite. It does not kill but only keeps the ants & insects away from attacking polymers.

One Pack System: The company also provides above repellents in One Pack system,

- Repellent + UV Master Batch

- Repellent + Color Master Batch

- Repellent+ UV + Color Master Batch

Key Features:

- Based on a combination of odoriferous and organoleptic repelling additives

- Low leachability, low controlled evaporation rate of chemicals

- Effective at very low addition level

- Compatibility with most polymers

- No change in physical, chemical or mechanical properties of polymers

- Approved by Accredited third party lab

- RoHS compliant and Toxicity data

- Human and Ecologically safe

- Cost effective.

Maillefer on Booth W1F24 at wire China 2016

Exceptional offering from the wire and cable manufacturing competence leader.

Maillefer is the only W&C technology supplier in the market with roots in cable manufacturing. This combined with the widest application coverage and over 4000 line deliveries has created unique competences available for its customers via several new products. Maillefer will introduce many novelties which enhance the competitiveness and responsiveness of wire and cable manufacturers. Competence counts.

Maillefer Factory System is a qualified concept to plan and realize a Greenfield factory with the lowest possible risk and cost. Maillefer is the only supplier in the global market having experience of the full delivery. Maillefer Factory System is a unique way to outsource a factory project right after customers have defined their end product, and it is suitable also for expansion of current production facilities.

Maillefer Consultation is a new service entity that is built around the wire and cable production process. It exploits the core knowledge into individual advice and process skill improvements of wire and cable manufacturers.

Maillefer will introduce a new Value Package to the Chinese market. Cable quality gets a totally new meaning with the new Round Value Package Premium with which production is controlled under very precise tolerances. This brand new curing concept guarantees utmost roundness in high voltage cable production.

The new Three Layer Crosshead THX 100/180 LR redefines extrusion for big conductor sizes and EHV insulation. Optimized Bi-flow distributors enable accurate wall thickness, centricity and roundness of the cable.

Maillefers’s application offering has grown by one to include aviation. Its experts are happy to tell customers more about its new Aviation & Aerospace Wire Insulation Lines TEL 15X/Enter and TEL 25X//Extend.

Maillefer’s material know-how is proven by demonstrations of how a rheometer for testing rubber curing parameters and our Curing Calculation Program NSS play together to give the best possible production run recipe. Visitors can even bring their own rubber cable samples to Maillefer’s booth for testing.

Visitors can also see the cable samples from Maillefer’s R&D Center’s Vertical Pilot Line for cables up to 750 kV and witness how the new Cable Roundness Meter CRM 180 works. Measurement results are examined in minute detail for sudden cable geometry errors. Finding the reason for cable geometry errors in the process makes it easier to maintain excellent quality in CV line production.

Maillefer is exhibiting at

booth W1F24 at wire China, 2016.

Maillefer at Booth 1/C12 in Wire& Cable India 2016

For Maillefer, competitiveness means increasing the lifetime value of technology in different production and market circumstances. Maillefer does it by empowering people, production and productivity – by equipping you with the right competency.

To better answer the diverse needs of wire and cable manufacturers worldwide, Maillefer portfolio is organized in three different solution levels − /Enter, //Extend and ///Explore. These solutions vary in capacity, cost, automation, flexibility, product range, space requirements and maintenance needs.

For a qualified concept to realize a complete factory with the lowest risk and cost, Maillefer introduces a new way to seize your business opportunities in both existing and new market segments− the new Maillefer Factory System.

Get to know the 30 know-how products − Maillefer Consultation with which one can maximize the value of technology, access the best practices and improve process based on the needs.

Maillefer’s new Round Value Package Premium guarantees utmost roundness in high voltage cable production. Visitors can see also how the new Cable Roundness Meter CRM 180 works which enables a totally new method for reliable and error free measurement of cable core roundness and concentricity of medium, high and extra high voltage cable cores.

Visitors may visit Maillefer’s booth to hear further details about its solutions, products and services on display which include among others the Quick Conductor Splicing QCS, FO Cable Secondary Coating Line OEL 40, MV CCV Line EPL 30, and HV CCV Line EPL 50.

Through the 24/7 Help Request, Service Support Desk, Spare Parts delivery and on-site Technical Visits, Maillefer’s broad range of services ensures that customers’ production achieves the best possible performance levels.

Medek & Schörner to Present Machines for Marking of Cables and Coating of Optical Fibres at Wire & Cable India 2016 in Mumbai

As the only company operating in this market segment, Medek & Schörner covers virtually the entire spectrum of machines for marking cables and coding optical fibres; in particular for power, telecom, data cables.

Medek & Schörner will be presenting the following state-of-the-art cable marking machines at the WIRE & CABLE INDIA 2016 fair in Mumbai:

Cable Marking Machines

- High quality gravure printers (LAN cables, control cables, etc.) for speeds up to 1200 m/min,

- Water Misting unit for the application of fine water dust for pre-cooling of the hot wire immediately after the extruder.

- Embossing meter markers / hot foil sequential meter markers for highest accuracy of length measurement (power cables, telecommunication cables, optical fibre cables, etc.)

- High performance ring markers for marking telephone wires, switchboard wires, automotive cables, LAN cables.

- Video system for monitoring the print quality of fast-running cable printing machines, e.g. allowing real-time inspection for bad quality and/or missing prints

- Laser Marking System for Cables

Optical Fibre Coating Systems

Top speed optical fibre processing systems:

- Optical fibre colour coding up to 3000 m/min;

- Ring marking of optical fibres at speeds up to 1150 m/min;

- Tight buffering up to 1300 m/min;

- Fibre ribbon production with excellent ribbon planarity and for speeds up to 1000 m/min.

- CFU Production of compact fibre units

- Copper wire insulation with UV varnishes (enamelled wire)

- Manufacture of dimension-sensitive precision micro flexible flat cables (FFC) using UV resins

For decades now, Medek & Schörner has been a world market leader in cable marking machines and optical fibre processing lines.

Medek & Schörner will be exhibiting at

Booth No.E14 (Austrian Pavilion) at

Wire & Cable India 2016.

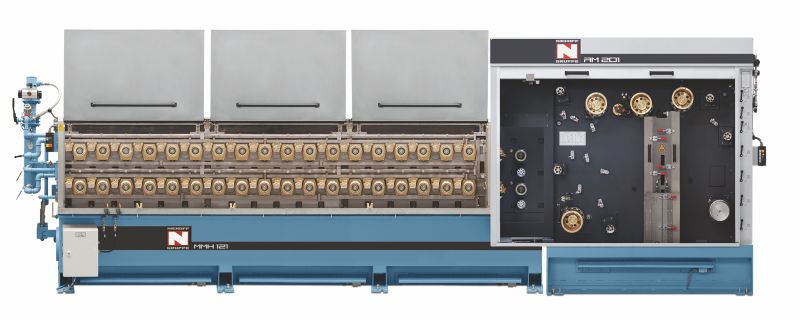

Niehoff to Display a 16-Wire Multiwire Drawing Line and a Pairing Machine at Wire & Cable India 2016

Maschinenfabrik Niehoff and Niehoff of India (NoI), its Indian subsidiary, will display at the Wire & Cable India 2016 trade show a 16 wire multiwire drawing line type MMH 121 + RM 201 made by NoI and a pairing machine type DSI 631 for data cables with backtwist pay-off type ARD 630 D.

Niehoff partner companies August Strecker, Germany (wire welding machines), Zeller + Gmelin, Germany (drawing lubricants) and H. Folke Sandelin AB (HFSAB), Sweden (horizontal lead extrusion and cable stripping, repair and recovery equipment) will also be in attendance at the Niehoff booth to introduce visitors to their products and services.

The multiwire drawing machine MMH 121 built by NoI under Niehoff licence is designed to draw simultaneously 16 wires in one level for a diameter range from 0.20 mm up to 1.05 mm. The MMH 121 is combined with an inline annealer type RM 201 and can work with a speed of up to 35 m/s. The MMH 121 is best suited for the production of electronic wires as well as for building wires. As the MMH machines are based on a modular principle, they can be built ideally adapted to the specific tasks of customers. The wires drawn on these machines exceed the most demanding specifications and processing requirements as far as physical properties and can be processed to multiwire bundles with outstanding characteristics. Up to now, more than 1,500 MMH lines are in operation world-wide.

The DSI 631 type double-twist stranding machine combined with an upstream backtwist pay-off type ARD 630 D has been designed for the stranding of insulated conductors into pairs and quads and the stranding of four conductor pairs into LAN cables. The machine is able to manufacture reliably LAN cables of all categories – even of future generations – as well as pairs with tape shielding, bus cables and other telecommunications cables.

The DSI stranding machines system includes a lot of additional auxiliary equipment, so that customer-specific production lines can be created and rapidly rebuilt depending on the order situation. Compared with other machines and process technologies, the combination possibilities of the DSI system generate significant financial advantages for the manufacture of certain products or a certain production performance.

Niehoff in India

Maschinenfabrik Niehoff has been active in India for more than 30 years. Niehoff of India (NoI), Niehoff’s subsidiary founded in 1997, is the market leader in India for rod breakdown, multiwire drawing machines and bunching machines. NoI operates a modern equipped factory near Hyderabad which was opened in 2007 and expanded in 2011/2012. NoI builds rod breakdown machines, annealers, spoolers, bunching machines and pay-offs conforming to Niehoff standards, mainly destined for the Indian market.

NoI is also responsible for the complete after-sales service and the reliable and fast supply of Niehoff’s customers with Niehoff Original+ parts for all Niehoff machinery.

Complete Solutions from a Single Source

Maschinenfabrik Niehoff develops and builds with an experience of more than 60 years all machinery needed for the production of non-ferrous metals wires and the further processing into automotive, data and special cables, with the exception of extruders. In addition, the portfolio contains technical assistance by professional specialists who speak the customers´ languages. The reliable supply with original Niehoff wear parts and spare parts, machinery inspection, refurbishment and maintenance measures as well as machine operator and maintenance training courses complete the range of services. Niehoff Group offers custom-tailored solutions from development and planning to turnkey projects of complete cable factories.

Niehoff will be exhibiting at booth E 02 at

Wire & cable India 2016, Mumbai.

PAN CHEMICALS to Present Its High-tech Drawing Lubricants at Wire & Cable India 2016

PAN CHEMICALS is offering its highest quality drawing lubricants and coatings, state of the art drawing processes and solutions, long experience and specialised technical service.

Over the last 25 years, PAN CHEMICALS has become one of the world leading manufacturers and suppliers of high tech drawing lubricants and coatings to the Wire Industry.

The production program includes:

- PANLUBE SDRY DRAWING LUBRICANTS: Full range of calcium, sodium and combined products for low and high carbon steel and stainless steel.

- PANLUBE L WET DRAWING LUBRICANTS: Complete range of oils, greases and pastes for wet drawing of low and high carbon, welding wire, stainless steel and non ferrous wire.

- PANCOVER LUBRICANT CARRIERS: Phosphates and non reactive coatings.

- PANFLUX FLUX FOR GALVANISING: Especially developed to improve the efficiency of the galvanising process by a uniform control of the reaction between the two metals, reducing operation costs and improving the quality of the zinc coating.

- PANCHEM AUXILIARY PRODUCTS: Degreasing agents, pickling inhibitors, protective products, activated charcoal, wiping pads and more.

PAN CHEMICALS has a strong emphasis on a close technical collaboration with its customers, and is deeply focused on the research and development of new products and solutions for specific applications. Particular attention is dedicated to the development of ecological products according to the new international regulations (Borax-free lubricants and coatings).

In addition to the chemical and auxiliary products, the engineering department can offer different solutions for mechanical descaling, coating and drying units, rotating die holders and die reconditioning equipment.

PAN CHEMICALS is offering its highest quality drawing lubricants and coatings, state of the art drawing processes and solutions, long experience and specialised technical service in its aim to become the world market leader for the highest quality lubricants.

PAN CHEMICALS will be exhibiting at

booth A 18 at Wire & Cable India 2016, Mumbai.

Sampsistemi to Showcase Its Innovative Wire Engineering Solutions at Mumbai Show

The Sampsistemi Multiwire Platform is available in three production solution levels, in order to meet all market requirements in terms of capacity needs and investment budget; the Sampsistemi Annealing Platform includes a number of technical features, such as multimotor technology, adjustable pre-heating length and a wire-walker before contact rings.

Once again, Sampsistemi is getting ready for the upcoming Wire show in Mumbai (October 5-7, 2016). Many innovative solutions for the wire and cable manufacturing will be on display to highlight the importance of this international event. Let’s have a look at some of the most interesting ones.

The Sampsistemi Multiwire Platform is available in three production solution levels, in order to meet all market requirements in terms of capacity needs and investment budget. These three levels are: Entry Level, Flexibility, Mass Production. These solutions vary in terms of production capacity, product range, flexibility, winding solutions and investment requested. The line on display at the Wire show in Mumbai has been specifically designed and engineered for Mass Production.

The Sampsistemi Multiwire Drawing Platform (DM Platform) is based on the splitting of gear transmission into two or more independent sections, with separate AC servomotors. This allows slip recovery between each section and at the inlet side. All motors are synchronised by means of a control motion system. Slipping reduction and the improvement in the quality of gear transmission, bearings and seals result in a reduction of energy consumption by 10-15% and in a consequent improvement of production costs. Die holders have been specifically designed to improve wire lubrication within the die, to reduce friction and to facilitate the wire cleaning, thereby enhancing the product quality and prolonging the die life. Zirconium oxide pulling rings are used to reach the best possible quality surface of the wire.

The Sampsistemi Annealing Platform includes a number of technical features, such as multimotor technology, adjustable pre-heating length and a wire-walker before contact rings. In addition, the cleaning device on contact rings ensures the integrity of the wire surface, the requested physical properties (mechanical strength, elongation, conductivity and resistance) and maintains the diameter and roundness of the wire. The control system is able to set up production parameters, in particular the kinematic ratio between each axis, in order to form a production recipe stored in the HMI panel. The Annealer Platform is completed with the latest development in annealing technology, in particular the development of the electronic equipment that reduces current distortion (THD-I) and energy waste (PF > 0.90).

Sampsistem will be exhibiting at

Hall 1, Booth C14 at Wire & Cable India 2016, Mumbai.

SIKORA to Exhibit at Wire & Cable India and wire China, 2016

SIKORA at the Wire & Cable India 2016 (Hall 1 Booth G48)

SIKORA continues its claim for Technology To Perfection: At the Wire & Cable India the Bremen based company is presenting a full program of well proven and innovative non-contact measuring, control, inspection and sorting devices for quality assurance and cost reduction in the wire, cable, optical fiber and plastics industries.

The product range includes X-ray and laser devices for the measurement of the diameter, eccentricity, ovality and wall thickness. In addition, lump detectors for the detection of non-conformities on the product surface as well as devices for monitoring the cleanliness of plastic material and for temperature measurement of PE melts will be shown.

Moreover, SIKORA will showcase the PREHEATER 6000 TC, a temperature controlled conductor preheating device that assures an optimum adhesion of the PE or other plastics on the conductor. In this context also the WIRE-TEMP 6000 will be presented, a non-contact conductor temperature measurement system that is now also available for diameters up to 50mm and thus suitable for installation in CV-lines.

With the PURITY SCANNER SIKORA offers a systems for 100% online inspection and sorting of plastic pellets that contributes to process optimization, quality assurance and cost saving.

In addition, visitors will get to know SIKORA’s sophisticated systems for quality assurance of optical fibers in the drawing tower. The product series is now complemented by a gauge head for measuring the fiber temperature as well as innovative equipment that gives information on the coating concentricity.

___________________________________________________________________________________________

SIKORA at Wire China 2016 (W1F62)

At Wire China, 2016 SIKORA is presenting a full program of innovative non-contact measuring, control, inspection, analysis and sorting systems for quality assurance, process optimization and cost reduction in the wire, cable, optical fiber and plastics industries.

The product range includes X-ray and laser devices for measuring the diameter, eccentricity, ovality and wall thickness.

With the PURITY SCANNER and the PURITY CONCEPT Systems, SIKORA presents novel systems for 100% online inspection and sorting of plastic pellets as well as for online or offline inspection and analysis of raw material.

Further highlights are the PREHEATER 6000 TC, a temperature controlled conductor preheating device and the WIRE-TEMP 6000, a non-contact conductor temperature measurement system.

Visitors will also get to know SIKORA’s sophisticated systems for quality assurance of optical fibers in the drawing tower.

.

___________________________________________________________________________________________

TROESTER Group to Exhibits at Wire & Cable India 2016

TROESTER will present the new TRENDSEAL, a variable Endseal System for CV Lines at the show; the variable Endseal TRENDSEAL eliminates the requirement for seal changes during product changes in all types of CV lines and thus decreases tool changing times.

Each CV Tube is equipped with one or more endseals in order to keep the cooling medium in process while the cable proceeds. Depending on the cable diameter to be processed, it is required to change the applicable sealing and support ring sets per cable type. In order to avoid operator errors and to minimize product changing times, TROESTER has developed the variable endseal system TRENDSEAL.

A concave shaped roller pair, driven by AC motor can be easily adjusted to seal a wide range of different conductor and cable diameters respectively. The rolls are coated with a high resistant rubber compound to ensure a perfect sealing behavior in abrasion proof design. Vulkollan seals or silicone lamellas and corresponding pressure and support ring sets are not required anymore!

TRENDSEAL is used in all types of CV lines (CCV, VCV and Rubber CV Lines) for universal sealing applications during the production of Medium and High Voltage cables. One TRENDSEAL replaces the conventional endseal systems like Single End Seal, Double End Seal and Lead Wire Seal.

TRENDSEAL minimizes scrap at start-up and eliminates complex handling and costs by having only one universal endseal device, said Dirk Schmidt, Sales Director Cable Machinery Division at TROESTER. Having approved its capabilities in long-term operation for more than two years in several cable plants, it is now ready for supply in new CV Lines with water and/or nitrogen cooling circuits and for upgrade of existing CV Lines.

Moreover, on the Wire India 2016, TROESTER will present information and new developments in the field of:

> CCV and VCV Lines for MV, HV and EHV Cables up to 1000 kV

> Rubber CV and CCV-Lines up to 35 kV

> Insulation and sheathing systems

> CV Tubes and components (e.g. variable Endseal type TRENDSEAL)

X-Compound, member of the TROESTER Group is specialized in complete systems for the compounding of plastics with the process steps conveying, melting, dispersing, mixing and degassing. X-Compound will present

> Kneader technology for the continuous compounding of HFFR (LSOH), PVC, XLPE, Semiconductive Materials and EPR/EPDM.

TROESTER GmbH & Co. KG is a world leading supplier of machines and complete lines for the cable manufacturing and rubber processing industry, comprising CV Lines for XLPE and Rubber Cables, Sheathing and Insulation Lines.

TROESTER will be exhibiting at

booth G30 (Hall 1).