To be able to draw using a minimum amount of product whilst generating a minimum of dust is a big concern of wire drawing companies.

CONDAT, worldwide leader for wiredrawing lubricants, answers this problem more than ever before with its latest generation of soaps.

These new soaps were developed with a primary objective of reducing the dust produced at the exit of dies and on capstans; but without compromising the excellent level of performance for which these products are renowned.

New VICAFIL and STEELSKIN products have been optimized; their adherence to the wire was reinforced in order to not over apply the lubricant. The consumption of lubricants is thus reduced to its bare minimum and dust is limited.

This reduction of dust particles therefore:

• Lowers the risk of exposure for the operators

• Improves the cleanliness of workshops

• Helps reduce industrial maintenance due to dust

• Limits the risks of inflammation or explosiveness of dust

VICAFIL and STEELSKIN soaps are available in different grain sizes according to the applications encountered and the wire diameter. To benefit from the best advice, CONDAT wiredrawing experts are available to support wire manufacturers in the optimization of their processes.

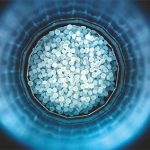

In addition to traditional soap powders, the whole CONDAT range is available in pellet form (see picture). The handling of pelletized soap is characterized by a significant reduction of dust emission. Moreover pellet soaps are very beneficial for a consistent lubrication.

The new technologies thus enable CONDAT to be ahead of the latest regulations and to better address the evolution of the chemical substances labeling system.