Backed by substantial investments in R&D and latest technology, HFCL Limited, India’s leading telecommunications equipment and solutions provider, has launched a range of next-generation OFC solutions tailored for diverse applications and installations, catering to the growing network expansions and bandwidth challenges of its customers. This was revealed by Mr. Harsh Pagay, Executive President – Optical Fibre & Optical Fibre Cable, HFCL, in an exclusive interview with Wire & Cable India.

Wire & Cable India: What types of fibre optic cables do you offer, and how do they differ in terms of performance and application? What has made them unique in the competition as well as efficient in applications?

Harsh Pagay: Over the last few years, HFCL has evolved into a technology-driven enterprise with a strong focus on developing cutting-edge, future-ready products. We are advancing a range of next-generation OFC solutions tailored for diverse applications and installations, catering to the growing network expansions and bandwidth challenges of our customers. These next-generation solutions include Intermittent Bonded Ribbon (IBR) Cables, compact 3rd generation micro cables, easy peel micro module cables (wet and dry), high-fibre-count flat ribbon cables in central loose tube and multi loose tube designs in SJSA (single jacket single armored) and dielectric variants, aerial cables for distribution and last mile connectivity in both dielectric and lashed variants with stringent CPR ratings along with variety of other FTTH cables. Most of these cables are designed in multiple variants for different applications, featuring compact designs and higher fibre densities customized to meet consumers’ needs.

With digital transformation happening across sectors, HFCL’s cables cater to a wide range of applications in industries like telecom, data centers, FTTH, FTTA, defense, and railways. Our high-fibre-count IBR cables are particularly well-suited for data centers, while our rugged armoured cables ensure high durability and performance in demanding environments such as railways, defense, and the oil and gas industries.

Additionally, we focus on developing passive connectivity solutions to complement our fibre optic cables. We offer a full range of connectivity solutions, including joint closures, FMS, fibre and copper cable assemblies (including CPRI cable assemblies for telecom applications), specialized breakout cables, jumper cables, MPO/MTP cable assemblies for sophisticated data center applications, and pre-connectorized drop cable assemblies for FTTH applications. HFCL’s competitive edge in passive connectivity solutions lies in a strategic blend of advanced technologies, in-house connectorization, and injection molding capabilities. This, combined with the reliability and cost-effectiveness of our comprehensive fibre and copper portfolio, positions us as a preferred partner in India and key global markets for customers seeking high-performance passive components across diverse sectors and applications.

Our leadership in the OFC industry is driven by our R&D efforts, particularly in micro cable designs. Our compact 144-864F IBR cables, with a record fibre density of 9.5 fibres per millimeter square, allow operators to maximize fibre capacity while minimizing space. Some of our cables are industry firsts, helping us achieve market leadership in this space. Cables such as the IBR microcable, 288-864F, have won prestigious international awards, including the Cabling Innovators Award, LIGHTWAVE Award, and MERIT Award, for their innovation and technology. HFCL has also received a patent for its ULW 96F cable, with many other applications pending approval, offering the company a first-mover advantage to capitalize on growing demand.

We utilize cutting-edge technologies in manufacturing, including advanced self-designed and specified machinery, stringent quality control processes, and a variety of the latest testing equipment to simulate harsh field environments, ensuring our cables meet the highest international standards. Continuous testing, field simulation, and iterations allow us to upgrade our products for maximum efficiency.

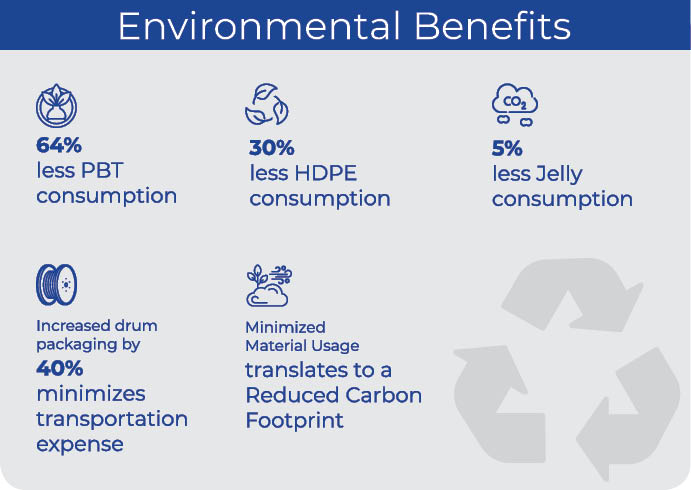

“We are shifting our product base towards greener alternatives. For example, our Optibend portfolio has achieved a 64 percent reduction in Polybutylene Terephthalate (PBT) consumption, 30 percent less High-Density Polyethylene (HDPE) consumption, and 5 percent less jelly consumption.”

WCI: What are the latest advancements in fibre optic technology, and how might they benefit the users? What state-of-the-art technologies do you use to manufacture them?

HP: Fibre technology is constantly evolving to address the never-ending network expansion and bandwidth challenges faced by operators. New technologies like multi-core fibre, hollow fibre, and ultra low attenuation fibres are aimed at reducing these challenges significantly. However, these technologies are still in the development phase and will take time to become cost-competitive, as the entire ecosystem around them needs to be built and matured. HFCL is closely analyzing these advancements and building its R&D and manufacturing capabilities to benefit from these technological opportunities, establishing itself as a leader in OFC technology.

To provide quick, cost-competitive solutions (with a turnaround time of 3-6 months), HFCL works closely with its customers and develops innovative OFC solutions that not only ease rollout operations but also offer significant commercial benefits in terms of reduced installation costs per fibre kilometer. HFCL has a proven track record of developing such solutions for tier-1 telecom operators.

Our robust R&D investments allow us to continuously innovate and meet evolving industry demands, enhancing network infrastructure requirements. We focus on developing indigenous OFC technology solutions, backed by our own intellectual property rights (IPR). We are also strengthening our cost competitiveness through backward integration, as well as automation and digitization of various manufacturing and business processes. The company has made substantial investments in upgrading and automating with the latest business solutions like SAP and Industry 4.0 automation. These efforts enable HFCL to strengthen its innovation and technology strategy while reducing dependence on external factors. Over time, HFCL has positioned itself as an end-to-end service provider for its customers.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

WCI: How closely do you coordinate with your clients when it comes to installation? Do you offer any warranties or guarantees on your fibre optic products and services?

HP: We work closely with our customers to provide comprehensive, end-to-end solutions, ensuring assistance at every stage for optimized performance. HFCL’s commitment goes beyond simply providing optical fibre cables; we also assist with the entire cable management process, from warehousing to distribution, including the disposal and recycling of wooden packaging. Our services include advising customers on the best duct sizes, cable blowing performance, and providing reports certifying blowing distances and speeds. We also guide them on choosing the right passive connectivity solutions to ensure seamless network integration and the highest level of operational efficiency.

Our optical fibre cables, when installed correctly, have a lifespan of over 25 years, during which they maintain optimal performance. However, these cables may be subject to physical damage, which could affect signal transmission. As a result, we offer a standard warranty of 12 months from installation or up to 18 months from the date of supply, whichever is earlier. That said, as mentioned, the life expectancy of our OFC is more than 25 years, with no significant degradation in performance.

“We have significantly expanded our optical fibre capacity from 12 million fibre kilometers (fkm) to 33 million fkm, and our optical fibre cable capacity from 25 million fkm to 30 million fkm.”

WCI: How important is sustainability to your operations? Elaborate some of the initiatives.

HP: Sustainability is not just a priority; it is at the core of our business operations. The global push for environmentally responsible practices has further fueled our efforts to reduce our carbon footprint. We have implemented several initiatives to minimize our environmental impact.

We have a dedicated sustainability team that tracks our progress against defined carbon reduction targets and explores new ways to further reduce our carbon footprint. Beyond our internal efforts, we are also monitoring our suppliers’ carbon footprint.

We are shifting our product base towards greener alternatives. For example, our Optibend portfolio has achieved a 64 percent reduction in Polybutylene Terephthalate (PBT) consumption, 30 percent less High-Density Polyethylene (HDPE) consumption, and 5 percent less jelly consumption. We have also replaced plastic packaging with cardboard and increased drum packaging by 40 percent, improving packaging efficiency and cutting emissions during transportation.

Some of our manufacturing plants run on 80-90 percent renewable energy sourced from solar or wind power, and similar efforts are underway at other facilities. We maximize solar energy usage within state regulatory limits. Our plants also have rainwater harvesting systems, and the harvested water is purified for sanitation and gardening purposes. Additionally, we recycle 100 percent of our process water to conserve resources. HFCL has been recognized with prestigious certifications for achieving ‘zero waste to landfills.’

Also Read: Polycab India: Making India Digital with High-Speed Connectivity Solutions

WCI: Please discuss some of the major challenges you often encounter.

HP: Macroeconomic factors such as rising capital costs, inflation, inventory buildup, and continued geopolitical tensions have temporarily impacted the demand for optical fibre cables. The OFC industry is currently seeing a softening in demand across key industries and global markets. However, we anticipate that the market will begin to recover in the last quarter of the current fiscal year (2024-25).

Another key challenge is the fierce competition and lack of a level playing field due to the dumping of low-quality OFCs by manufacturers benefitting from significant export subsidies from their countries. Governments worldwide are beginning to recognize this unfair advantage, and anti-dumping duties are being implemented to tackle the issue, ensuring fair competition for players like HFCL, which focuses on long-term customer relationships and fair trade practices.

Despite these challenges, we are optimistic about the growing demand for OFCs driven by projects like BharatNet-III, the expansion of 5G networks, FTTH (Fibre-To-The-Home) implementations, and the hyper-scaling of data centers globally. In response to the slowdown in optical fibre cable revenue, HFCL has expanded its business in passive connectivity solutions, becoming an end-to-end solution provider for governments, telcos, and enterprises.

WCI: How are you positioned in the market, in terms of market share and production capacity? Where do you see yourself in 2024-25?

HP: HFCL has maintained a leadership position with over 60 percent market share in the Indian OFC market. We have also successfully established ourselves as a trusted partner in key global markets, including the UK, Europe, the US, the Middle East, and Africa. To meet rising demand, we have significantly expanded our optical fibre capacity from 12 million fibre kilometers (fkm) to 33 million fkm, and our optical fibre cable capacity from 25 million fkm to 30 million fkm.

We are determined to capitalize on global opportunities and boost revenue from international operations. To achieve this, we are actively developing new product portfolios that meet international standards and appointing employees, agents, and distributors in key markets like the UK, US, the Middle East, and Africa.