Mixer S.p.A. has always been “Wired Differently,” carefully listening to customers’ needs and preferences, and continues to be a trusted partner for companies worldwide seeking innovative materials. The company stands out in providing customized solutions that meet the unique requirements of its customers, from the product design to the delivery logistics, ensuring reliability and competitiveness in today’s market.

Mixer S.p.A. is an Italian company with more than 25 years of expertise, dedicated to fulfilling customers’ needs through comprehensive support and collaborative strategy development. Founded in 1996, the company has consistently prioritized innovation and reliability, driving continuous improvement and growing its expertise in wire and cable compounds. By choosing compounds in the form of pellets rather than strips, Mixer provides to its customers significant advantages, including the optimization of transportation and storage, as well as consistency and homogeneity.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

PRODUCT PORTFOLIO

Among the numerous products supplied for different applications in the cables market, the Mixer’s portfolio includes a wide range of rubber-based solutions, ensuring high-quality standards throughout the entire manufacturing process, from the raw material selection to the final product testing. The Italian company has solidified its position worldwide as a reference point for medium voltage insulation, creating a specialized production line that emphasizes meticulous attention to all details and achieving complete cleanliness.

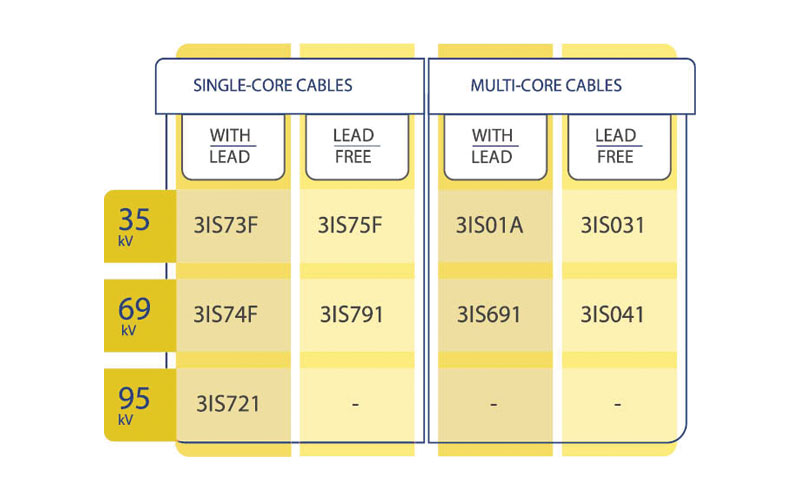

The medium voltage insulation portfolio includes grades for applications up to 95kV, based on full EPR, EPDM, and EPDM-PE blends, comprising solutions with and without lead. The lead-free grades have been specifically developed to minimize the environmental impact, keeping excellent insulating performances in compliance with the lead-free directive necessary to access the European market, the RoHS regulation. All these compounds are fully compliant to the international standards for 90°C and 105°C operating temperatures and they can be employed both for static and dynamic applications, even in extremely cold environments down to -40°C. Moreover, taking advantage of the elastic behaviour of the fully rubber-based compounds, solutions suitable for multicore cables have gained momentum in view for voltages up to 69 kV.

Also Read: Kasturi Metal Composite: Translating Customer Requirements into Innovations

RECENT DEVELOPMENTS

Recently, Mixer has enriched its offer with increased flexibility grades that avoid the scorch issues especially at high extrusion speed. EKOPREN® 3IS73F and 3IS75F for applications up to 35 kV, and EKOPREN® 3IS74F for applications up to 69 kV represent such solutions, always maintaining the highest level of performance. Besides, due to the increasing interest for rubber cables suitable for applications up to 95 kV, a new grade named EKOPREN® 3IS721 is a result of a deep investigation and study of the raw materials capable of providing the highest quality in terms of insulation behaviour and electrical properties. Typical electrical tests are the volume resistivity, the dielectric strength, and the loss factor.

Finally, focusing the attention on the multicore applications, it is worth noting the new grades such as EKOPREN® 3IS01A and EKOPREN® 3IS691 which, together their lead-free counterparts, ensure low deformation in processes that involve a second step of peroxide-induced crosslinking for the sheathing extrusion. These grades are capable of maintaining constant the diameter of each insulation core against the high pressure generated by the outer sheath, ensuring a high level of flexibility and avoiding partial discharges or breakdown issues. Moreover, among them, EKOPREN® 3IS041 consists of a new grade for the wind turbine applications. By paying close attention to every detail, the diverse range of products in the medium voltage compounds field includes environmentally friendly lead-free solutions and fully rubber-based blends suitable for multicore cables.